13

Test new wheels for cracks and maintain the

existing sequence of retaining hardware. Be sure

the grinder is unplugged before attempting repairs.

To change a wheel (refer to Figure 5):

1. Disconnect grinder from power source.

2. Move spark guard and tool rest away from the

wheel.

3. Remove the guard cover using a Phillips or

flathead screwdriver.

4. Stabilize the wheel by holding the opposite

wheel firmly.

5. Unscrew the arbor nut with a 1" wrench.

Note

: Turn the locking nut on the right-hand

wheel counterclockwise to loosen. Turn the

locking nut on the left-hand wheel clockwise to

loosen.

6. Remove the outer flange and wheel.

7. Clean flanges. Check the flanges to make sure

they are flat. Wheel flanges that are not flat will

cause the wheel to wobble.

8. Install the inner flange, wheel, outer flange,

and nut on the arbor. Tighten the nut.

Do not

over tighten

– this may cause the wheel to

crack, or the flanges to bend.

9. Replace the guard cover. Adjust spark guards

and tool rests to 1/16" clearance from wheel.

10.3

Cleaning

Metal shavings may still be hot

from recent grinding operations. Make sure

shavings and debris are cold before cleaning

the grinder.

Brush all shavings from the motor housing, tool

rests, and wheel guards.

Check grinding wheels for cracks and chips.

Replace if damaged.

Avoid the use of the following

cleaning chemicals or solvents: gasoline,

carbon tetrachloride, chlorinated solvents,

ammonia and household detergents containing

ammonia.

10.4

Lubrication

All motor bearings are permanently lubricated by

the manufacturer and require no additional

lubrication.

11.0

Optional accessory

The bench grinder can be mounted to the JET

pedestal stand (optional accessory, p/n 577172),

which has an adjustable platform with coolant cup.

See Figure 10. To order, contact your dealer or call

Walter Meier customer service at the phone

number on the cover.

Figure 10: optional stand

Содержание JWBG-8

Страница 16: ...16 13 1 1 JWBG 8 Bench Grinder Exploded View ...

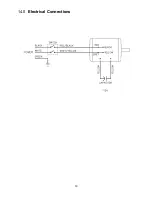

Страница 19: ...19 14 0 Electrical Connections ...