Maintenance

12.1

Maintenance Requirements

All maintenance must be

carried out with the

power switched off

. Failure

to comply may result in serious injury!

On completion of maintenance, ensure that

replaced parts and/or any tools used have been

removed from the machine before starting it up.

12.2

Periodic Maintenance

Remove chips from the machine, preferably with

a cloth

Remove chips from the coolant tank and change

coolant regularly (see

Coolant

section)

Top up the coolant level (see

Coolant

)

Check the wear of the blade and change if

necessary (see

Changing the Saw Blade

)

Empty the chips out of the base.

Clean the vise and lubricate all the joints and

sliding surfaces, using good quality oil.

Attend to daily, weekly and annual lubrication

recommendations (see the

Lubrication

section)

12.3

Coolant

The

coolant tank access door

is located on the

back of the cabinet stand. Remove four hex cap

screws with a 5mm hex wrench. Check coolant

level in the coolant tank periodically and top off if

necessary. Coolant can also be added by pouring

directly on the table, which will drain into the tank

through the

chip strainer

.

Remove excess chips periodically from the tank.

Use the coolant level gauge to check the coolant

level.

12.4

Changing the Saw Blade

The cold saw must not be

connected to the power source when changing

saw blades. Failure to comply may result in

serious injury!

To change the saw blade:

1.

Switch off the machine.

2.

Release the lower disc guard.

3.

Move the lower guard upwards.

4.

Remove the blade and replace it with a new

one.

5.

To secure the saw blade, reverse the

preceding steps.

12.5

Lubrication

For long life and trouble-free operation, it is

essential that this machine be kept well lubricated.

The vise and leadscrew should be oiled daily. Pivot

joints and bearings should be greased weekly.

Check the gearbox oil level weekly; full level is top

of sight glass with head in full up position. The

gearbox oil should be changed annually.

Recommended Lubricants:

Gearbox

Use Texaco Meropa 460 or equivalent.

Grease fittings

Texaco Starplex 2 or equivalent

Vise and Leadscrew

Regal R & O 68

12.6

Coolant System

This coolant system can operate with either a

soluble oil base coolant or water-soluble synthetic

coolant. Coolant should be changed regularly.

Some recommended brands are

DoAll

and

Lenox

.

These coolants are available at your local industrial

distributor.

Coolant Type:

Soluble Oil Base

Water-Soluble Synthetic Coolant

Содержание J-FK350-4

Страница 1: ...Operating Instructions and Parts Manual Ferrous Manual Cold Saws Models J FK350 2 J FK350 4...

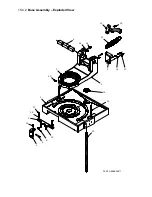

Страница 15: ...15 1 2 Head Assembly Exploded View...

Страница 21: ...15 5 2 Manual Vise Assembly Exploded View...

Страница 23: ...15 6 2 Guard Assembly Exploded View...

Страница 26: ...Wiring Diagram...