5

5.0

Setup and assembly

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

5.1

Shipping contents

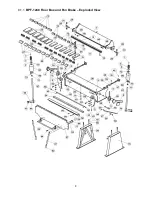

Refer to Figures 1 and 2.

1 Box and pan brake (not shown)

2

Support legs – A

1

Curved handle – B

2

Straight handles – C

1

Stop rod – D

2

Counterweight assemblies – E

1

Stop rod pin – F

1

Stop collar – G

1

Hex key, 6mm – H

4

Hex cap bolts, M12x40 – HP1

8

Hex cap bolts, M10x40 – HP2

1

Flat washer, M16 – HP3

8

Flat washers, M12 – HP4

8

Flat washers, M10 – HP5

8

Lock washers, M12 – HP6

8

Lock washers, M10 – HP7

4

Hex nuts, M12 – HP8

1

Hex nut, M16 – HP9

1

Cotter pin – HP10

Figure 1

Figure 2

5.2

Tools required for assembly

6mm hex key (provided)

pliers

5.3

Unpacking and cleanup

1. Remove all contents from shipping crate and

compare to the contents list in this manual. If

shipping damage or any part shortages are

identified, contact your distributor. Do not

discard packing material until brake is

assembled and operating satisfactorily.

2. Carefully clean all rust protected surfaces with

a mild solvent or kerosene and a soft rag. Do

not use lacquer thinner, paint thinner, or

gasoline – these will damage painted surfaces.

3. Coat all machined surfaces with a light coat of

oil to inhibit rust.

5.4

Assembly

Refer to exploded view if additional clarification is

needed for assembly.

1. Remove bolts holding support legs and brake to

pallet.

2. Locate brake in a dry, well-lighted area with a

sturdy, level floor. Machine location must allow

room for loading and offloading stock, and

access on all sides for maintenance.

3. Use hoist or forklift to carefully lift brake onto

support legs. Secure with M12 bolts, washers

and nuts (HP1/HP4/HP6/HP8).

Do not allow anyone

beneath brake while moving it into position

and until it is secured on support legs.

4. Verify that brake is level; use shims if

necessary. Secure support legs to floor with

appropriate fasteners, such as lag bolts (not

provided).

5. Install counterweight assemblies to left and

right hinges with M12 bolts, lock washers and

flat washers (HP1/HP4/HP6). See Figure 3.

Figure 3