17

EGH1740 | EGH1760

Fig. 18

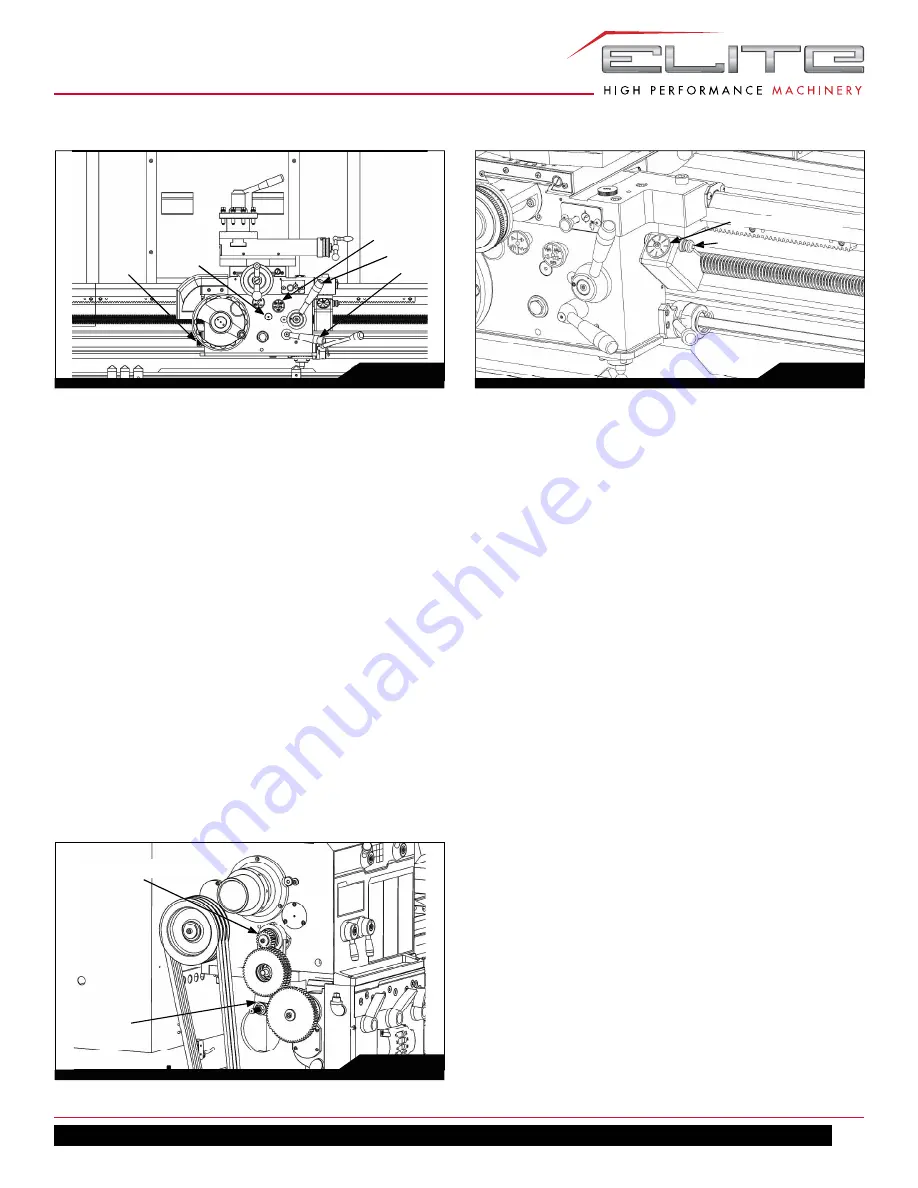

9.6 THREADING DIAL INDICATOR

For threads cutting:

• Tighten the handnut to retain indicator in when

engaging the indicator with the leadscrew. When not

required, release hand-nut and swing indicator out of

engagement.

•

To cut threads with an even number per inch, the

leadscrew nut can be closed as any line on the dial

passes the datum mark.

• To cut threads with an odd number per inch, close

the leadscrew nut at any NUMBERED line.

• Fractional threads of 1/2 or 1/4 T.P.I. may be cut by

closing the nut at the SAME NUMBERED LINE on

each pass of the tool.

• This dial can not be used with an IMPERIAL

leadscrew to cut metric threads, D.P., M.P. which are

shown on gear box data plate. For the threads being

shown, the leadscrew nut must be kept closed. Use

apron control lever after each thread cutting when

the tool is withdrawn to original start of thread cutting

operation.

Fig. 19

Multi-start threads can be cut on a lathe in three ways:

1. By repositioning the compound (top) slide one pitch

forward for each start. Note that the slide is normally

set at 90º to the axis of the machine cross-slide. The

accuracy of this method depends upon the skill of

the operator.

2. By using an accurately divided driver plate and

turning the work-piece one division forward for each

start.

3. By advancing the driver gear a calculated number

of turns to advance the spindle by one pitch of the

thread to be cut. The accuracy of this method is

that of the machine.

• With all series lathes, two ratios exist between

the spindle and driver gear shift, i.e. the LOW

range where the ratio is 1:2 and the HIGH range

where the ratio is 2:1

• In order to use this method, the number of

teeth on the driver gear must be divisible by

the number of starts being cut. The driver gear

is then advanced by half this number of teeth

when in LOW range. And conversely, by twice

the number of teeth when in HIGH range.

• On the standard end gear train for this machine

the driver gear has 24 teeth; so that two, three

or four start threads, can readily be cut. For

other odd numbers of start a choice must be

made of methods 1 or 2.

9.7 CROSS SLIDE AND TOP SLIDE

•

A solid topslide is fitted as standard equipment to

the cross-slide mounted on a swivel base which is

marked 0-90-0-90º for accurate indexing.

•

Handwheel dials are graduated in inch or metric

divisions to suit the operation.

A

D

C

Fig. 20

Handnut

Threading dial indicator

F

Gear 24T for Imperial leadscrew

(Gear 28T/22T for Metric leadscrew)

End Gear Train

Содержание 892100

Страница 21: ...21 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Страница 22: ...22 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Страница 23: ...23 EGH1740 EGH1760 HEADSTOCK ASSEMBLY ...

Страница 24: ...24 1700 Series Lathe HEADSTOCK ASSEMBLY ...

Страница 28: ...28 1700 Series Lathe GEARBOX ASSEMBLY ...

Страница 29: ...29 EGH1740 EGH1760 GEARBOX ASSEMBLY ...

Страница 33: ...33 EGH1740 EGH1760 APRON L H ASSEMBLY ...

Страница 34: ...34 1700 Series Lathe APRON L H ASSEMBLY ...

Страница 39: ...39 EGH1740 EGH1760 4 WAY TOOL POST ...

Страница 41: ...41 EGH1740 EGH1760 SADDLES ASSEMBLY ...

Страница 42: ...42 1700 Series Lathe SADDLES ASSEMBLY 2 ...

Страница 45: ...45 EGH1740 EGH1760 BED AND SHAFTS ASSEMBLY ...

Страница 48: ...48 1700 Series Lathe END GEAR ASSEMBLY ...

Страница 50: ...50 1700 Series Lathe MAIN MOTOR ASSEMBLY ...

Страница 52: ...52 1700 Series Lathe CABINET AND PANEL ASSEMBLY FRONT MOVEABLE CHIP TRAY OPTIONS ...

Страница 56: ...56 1700 Series Lathe CONVENTIONAL TAILSTOCK ASSEMBLY ...

Страница 58: ...58 1700 Series Lathe STEADY REST ASSEMBLY ...

Страница 62: ...62 1700 Series Lathe 892156 5C COLLET CLOSER OPTIONAL ...

Страница 64: ...64 1700 Series Lathe 892157 TAPER ATTACHMENT OPTIONAL ...

Страница 68: ...68 1700 Series Lathe 12 0 WIRING DIAGRAM ...