The RPM Readout shows the spindle

speed

Use the toggle switch (B) to reverse

the spindle direction.

The headstock lock handle locks the

headstock in position. Unlock handle to

position the head along the lathe bed.

6. Machine operation

6.1 Correct operating position

Always support the tool on the tool rest

and guide with the palm of your hand

keeping your fingers closed.

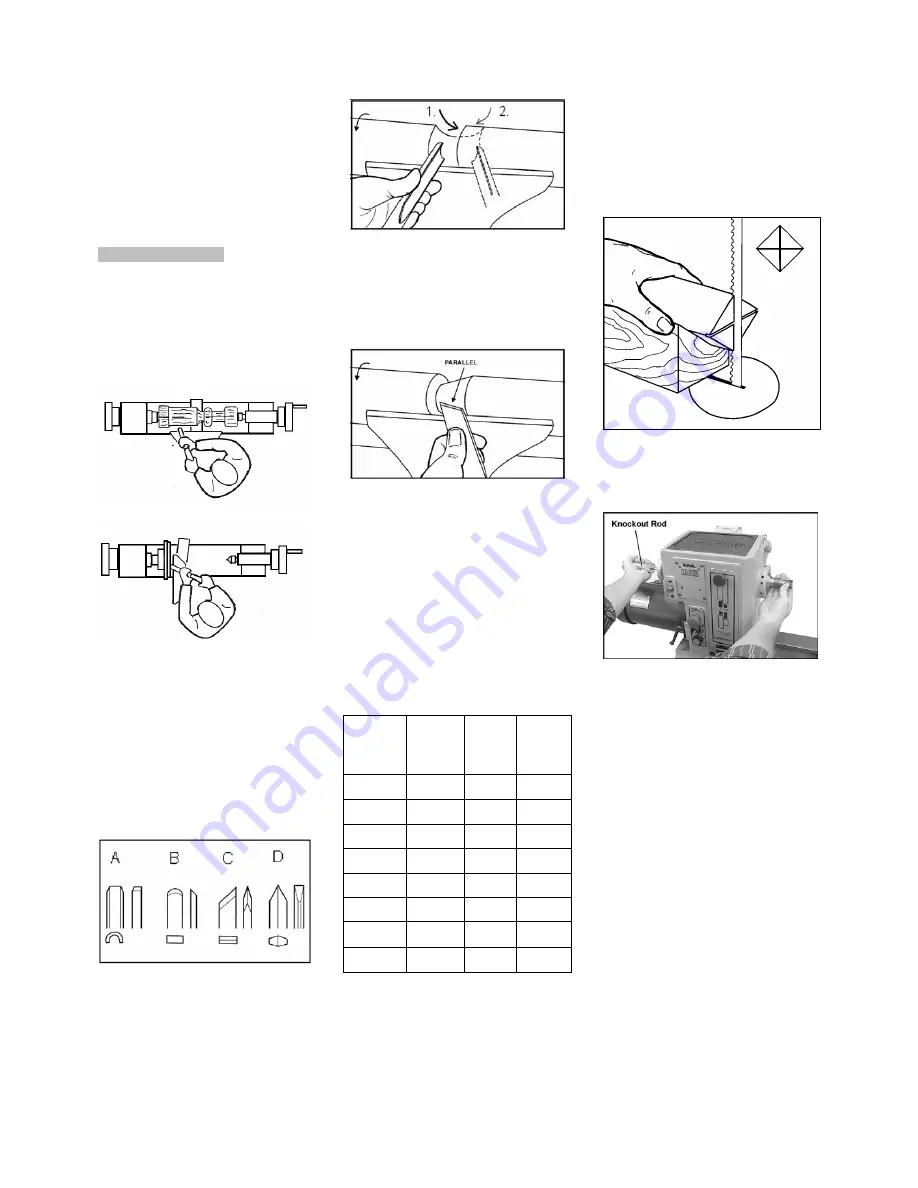

(see Fig. 15 )

Fig 15

6.2 Tool selection

Successful wood turning does not

result from high speeds, but rather,

from the correct use of turning tools.

A perfect and sharp wood turner tool is

a precondition for professional wood-

turning.

Major tools:

Fig 16

Gouge (A, Fig 16)

, used for rapidly cut

raw wood into round stock, for turning

bowls and plates, for turning beds,

coves and other detail (Fig 17).

Fig 17

Scraper (B, Fig 16)

, used for diameter

scraping and to reduce ridges.

Skew Chisel (C, Fig 16),

used to

make vees, beads, etc. (Fig 18). The

bevel of scew is parallel to the cut.

Fig 18

Parting tool (D, Fig 16),

used to cut

directly into the material, or to make a

cut off. Also used for scraping and to

set diameters.

6.3 Speed selection:

Use low speeds for roughing and for

large diameter work. If vibrations

occur, stop the machine and correct

the cause.

See speed recommendations.

Speed recommendations

Workpiec

e

Diameter

mm

Roughin

g

RPM

Genera

l

Cutting

RPM

Finishin

g

RPM

< 50

1500 3200 3200

50-100

700 1600 2500

100-150

500 1100 1600

150-200

370 800 1200

200-250

300 650 1000

250-300

250 500 800

300-350

220 450 700

350-400

180 400 600

6.4 Turning between centres

With a ruler locate and mark the centre

on each end.

Put a dimple in each end of the shock.

Extremely hard woods may require

kerfs cut into the spur drive end of

stock (see Fig 19).

Fig 19

The spur drive centre locks into the

cleaned spindle taper and can be

removed with the knockout rod (Fig 20)

Fig 20

Mount the centred workpiece between

the spur drive centre and the tailstock

mounted live centre

Turn the tailstock hand wheel until the

live centre well penetrates the

workpiece. Reverse the hand wheel by

one quarter turn and lock the tailstock

spindle.

Turn the workpiece by hand to see if it

rests securely between centres and

can be rotated freely.

For turning between centres the tool

rest is set appr. 3mm higher than

centre line (Fig 21 and 22).