16 of 20

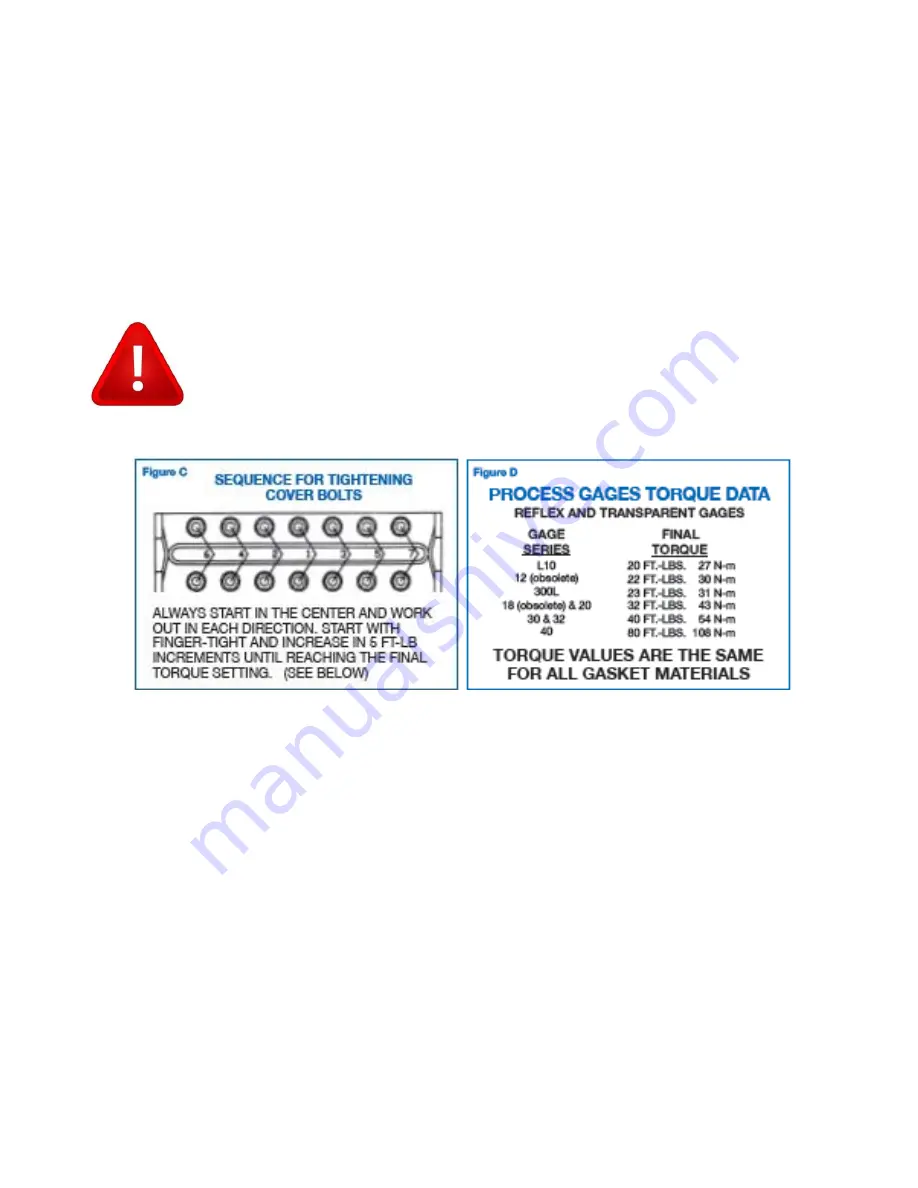

11. Tighten the nuts finger-tight, working from the middle set, alternating outward (see

Figure C below). Next, tighten with a torque wrench in the same sequence in 5 ft.-lb.

(6.7 N-m) increments until the final torque value is achieved (see Figure D below).

With the torque wrench still set at the final value, make one final pass moving from left

to right to confirm final torque value on all nuts. Moving from left to right will eliminate

any crosstalk that may have occurred between bolt sets.

Warning:

Moving in this sequence shall only be done after achieving factory

torque value in Figure D below. Failure to achieve final torque using any

sequence other than as described in Figure C (below) may result in glass

breakage at time of assembly or at pressurization.

12. Note: Gages should be re-torqued prior to being put into service. Additionally, new

gaskets can become permanently compressed after a short time in service (especially

if the gage operates hot). This causes slight leaks or apparent loosening of bolts. (If

the gage is installed in high temperature service and it is not equipped with spring

washers, a hot torque procedure must be performed.)

13. All reassembled gages should be hydrotested for a minimum of five minutes before

returning the gage to service. Recommended hydrotest pressure is one and half (1.5x)

times the gage rating as seen on the tag.