5

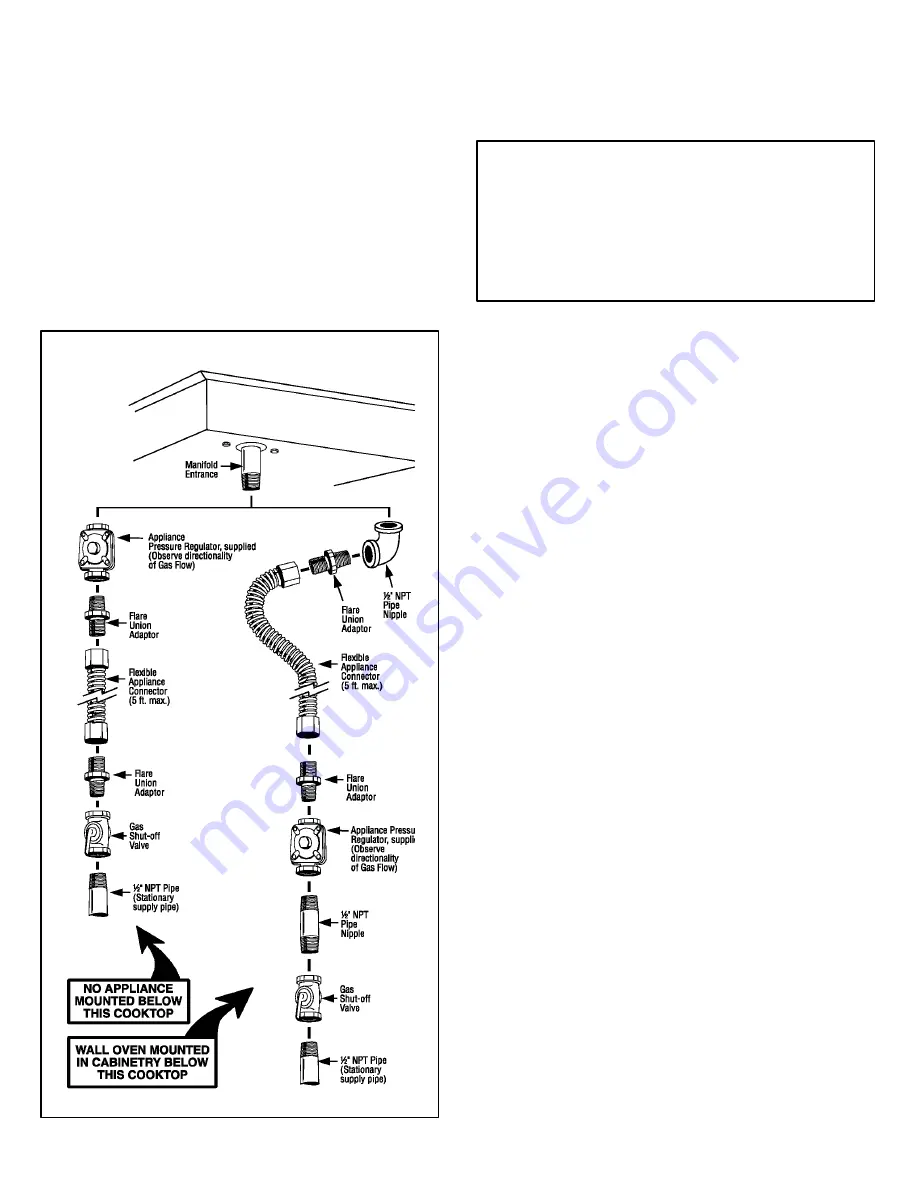

ALTERNATIVE PIPING METHODS TO CONNECT

APPLIANCE TO GAS SUPPLY

A TRAINED SERVICEMAN OR GAS APPLIANCE INSTALLER MUST

MAKE THE GAS SUPPLY CONNECTION. Leak testing of the appliance

shall be conducted by the installer according to the instructions

given.

Unless prohibited by local codes or ordinances, a new A.G.A. -- Certified,

flexible metal appliance connector may be used to connect this appliance

to its gas supply. The connector must have an internal diameter not less

than nominal 1/2

²

NPT pipe and be no more than 5 feet in length. A 1/2

²

NPT x 1/2

²

flare union adapter is required at each end of the flexible

connector. If a flexible connector is used assure that both the appliance

pressure regulator and manual shut-off valve are joined solidly to other

permanent hard piping (either gas supply or the appliance manifold) so as

to be physically stationary. See illustrations below:

FIGURE 5

ILLUSTRATIVE ALTERNATIVE PIPING

Elbow

CAUTION:

Do not attempt to attach the flexible connector directly to an

external pipe thread. Connection requires flare union adapters.

IMPORTANT

Apply a non-corrosive leak detection fluid to all joints and fittings in the

gas connection between the supply line shut-off valve and the range.

Include gas fittings and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing around fittings

and connections will indicate a leak. If a leak appears, turn off supply line

gas shut-off valve, tighten connections, turn on the supply line gas shut

off valve, and retest for leaks. Never test for gas leaks with an open

flame.

PRESSURE TESTING

The appliance must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2

PSIG (3.5 kPa).

This appliance, as well as its individual shut-off valve, must be

disconnected from the gas supply piping system during any pressure

testing of the system at test pressures in excess of 1/2 PSIG (3.5 kPa).

When checking appliance regulator function, make certain pressure of

natural gas supply is between 6 and 14 inches of water column or, if

converted for LP gas, between 11 and 14 inches.