12

3.4. Items to be checked after installation.

S/N

Check items

YES NO

1

Are the posts vertical to the floor?

2

Is the oil hose well connected?

3

Is the steel cable well connected?

4

Are two platforms well connected?

5

Are electrical connections, right?

6

Are the rest joints firmly screwed?

7

Are all items need lubricating added with grease?

4. Operation instructions

4.1 Precautions

4.1.1 Check all the joints of oil hose. Only when there is no leakage, the lift can start work.

4.1.2 The lift, if its safety device malfunctions, shall not be used.

4.1.3 The machine shall not lift or lower an automobile if its center of gravity is not positioned midway of the platforms. Otherwise,

the Jema Autolifte as well as our dealers will not bear any responsibility for any consequence resulted thereby.

4.1.4 Operators and other personnel concerned should stand in a safety area during lifting and lowering process.

4.1.5 When the platforms rise to the desired height, switch off the power at once to prevent any mal operation done by

unconcerned people.

4.1.6. Make sure the safety lock of the lift is engaged before start working under the vehicle and no people under the vehicle

during lifting and lowering process.

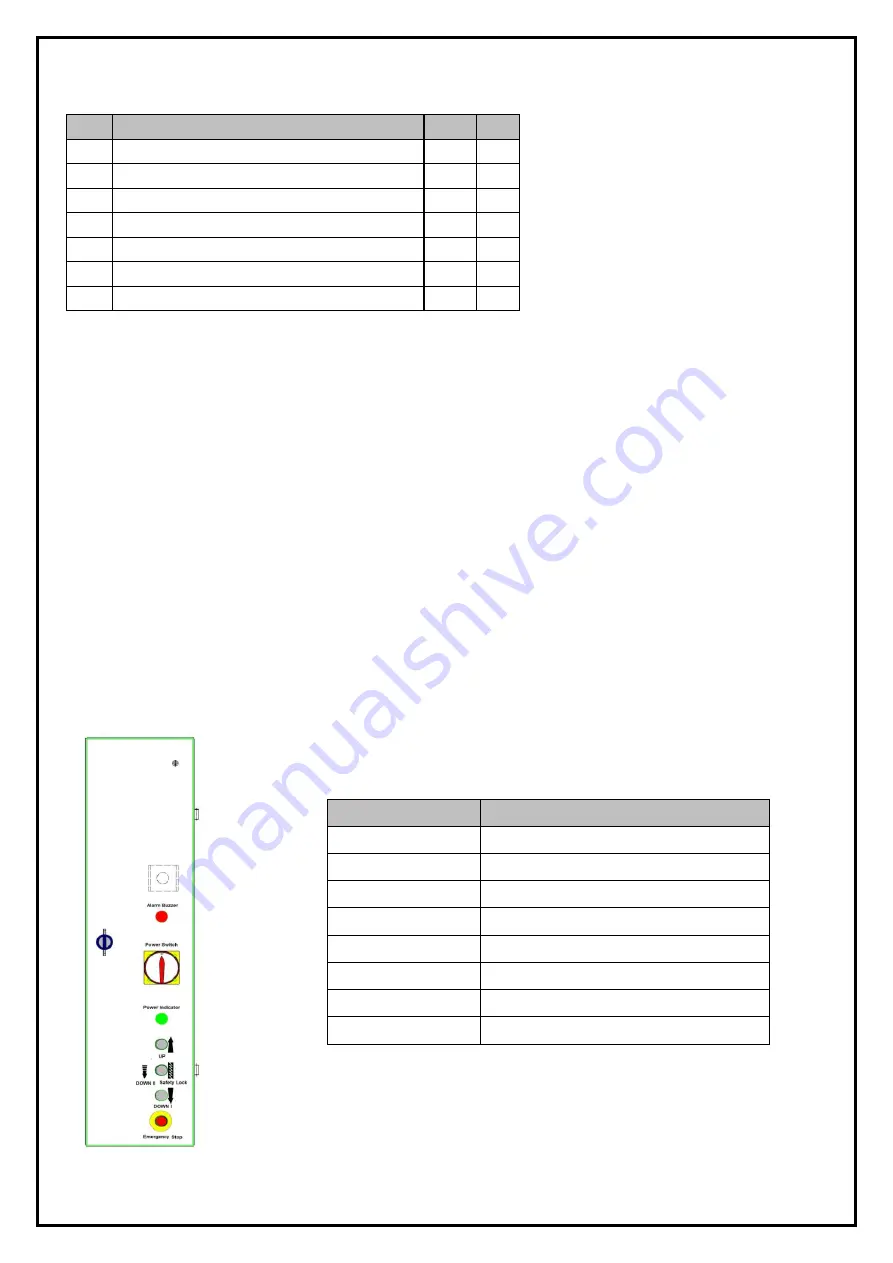

4.2 Descriptions of control box

Description

Function

Alarm buzzer

Low height alarm

Power switch

Control power connection

Power indicator

Show if power is connected

UP button

Control the UP movement

Safety lock

Safety lock engaged

DOWN I button

Control down movement

DOWN II button

Control down movement

EMG.Stop

Ensure safety in emergency conditions

Содержание JA5500F

Страница 19: ...19 Annex2 Overall diagram...

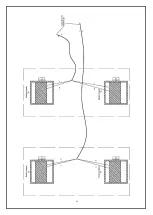

Страница 20: ...20 Annex3 Floor plan Annex 4 Steel cable connection...

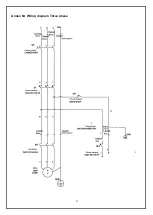

Страница 22: ...22 Annex 6 Wiring diagram Three phase...

Страница 23: ...23 Electric wire connections in control box Picture of the control box and connections...

Страница 24: ...24...

Страница 25: ...25...

Страница 26: ...26...

Страница 27: ...27 Annex7 Separate diagrams for the lift JA5500F...

Страница 35: ...35 Annex9 Size and weight requirements on vehicles...

Страница 36: ...36...