h

5

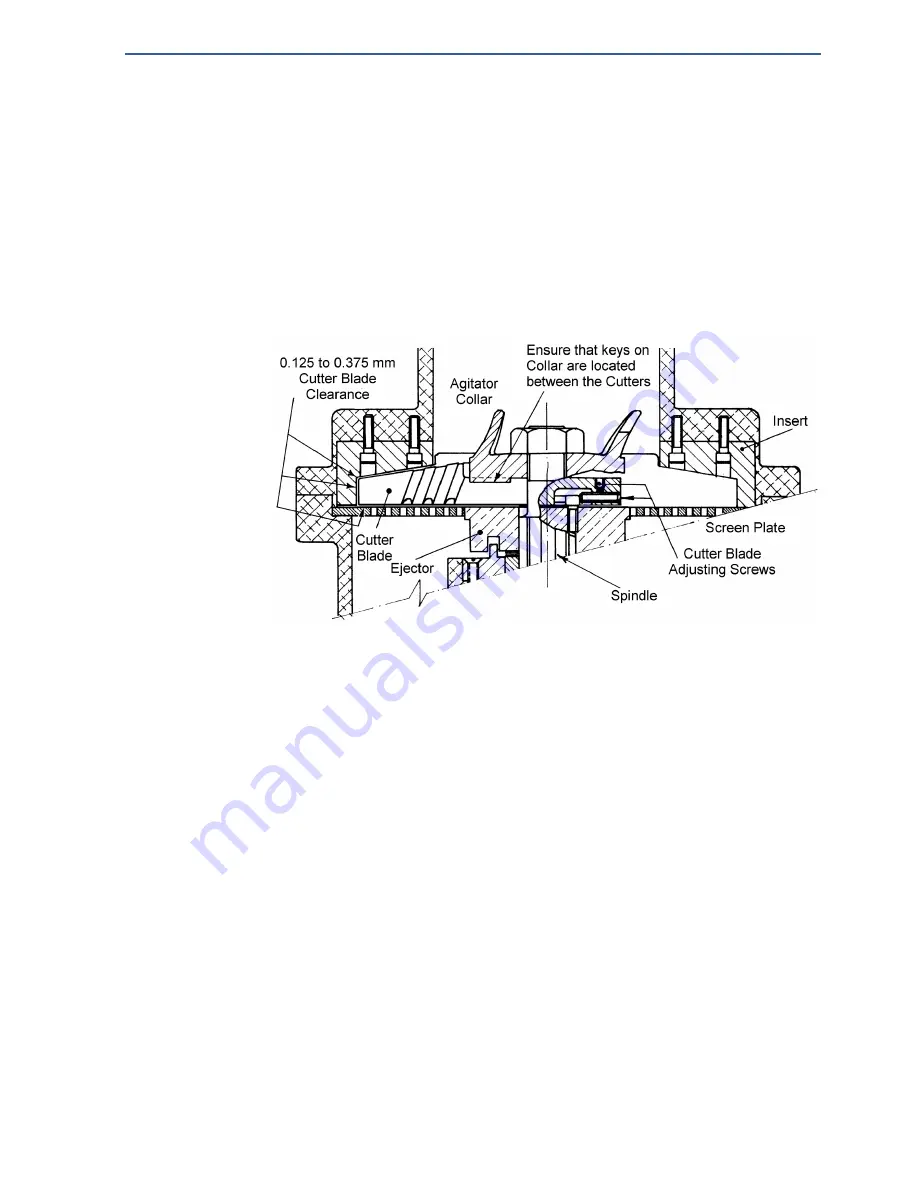

The Cutting System

The most critical adjustments in the Cutter Grinder are the location and condi-

tion of the cutter blades. If these are maintained correctly, the

h

Cutter

Grinder Model CG02

will give long and effective performance. Incorrectly ad-

justed blades can cause motor overload and could pose a safety hazard, so note

these steps carefully. The cutter blades should be sharpened regularly according

to the directions in the section

MAINTAINING THE CUTTING COMPONENTS

.

The cutter blades must always have the correct angles and sizes maintained, and

have a clearance from the screen plate and head inserts of between 0.125mm and

0.375mm. This clearance is maintained through the brass spacer rings under the

ejector and the adjusting screws in the end of each cutter blade.

The clearance should be minimal to provide optimum performance and careful

adjustment will be rewarded with excellent performance. For machines doing

heavy duty, a light touch up for the blades each day on a fine grinding stone will

ensure an uninterrupted work cycle.

Never allow the cutter blades to be sharpened beyond their useful, safe life – re-

fer the section entitled

MAINTAINING THE CUTTING COMPONENTS

. When re-

placing cutter blades onto the ejector during reassembly make sure that they are

matched by the numbers to the correct key. The head inserts do not accomplish

the cutting within the Cutter Grinder so they should not need to be kept as sharp

as the cutter blades and should have a longer life.

Always keep the mating surfaces of the head and midbody free of any foreign

matter and never allow contamination of the grease in the area of the bearing.

Figure 2. Section of Head & Midbody with Cutter Blades, Inserts & Screen Plate