11

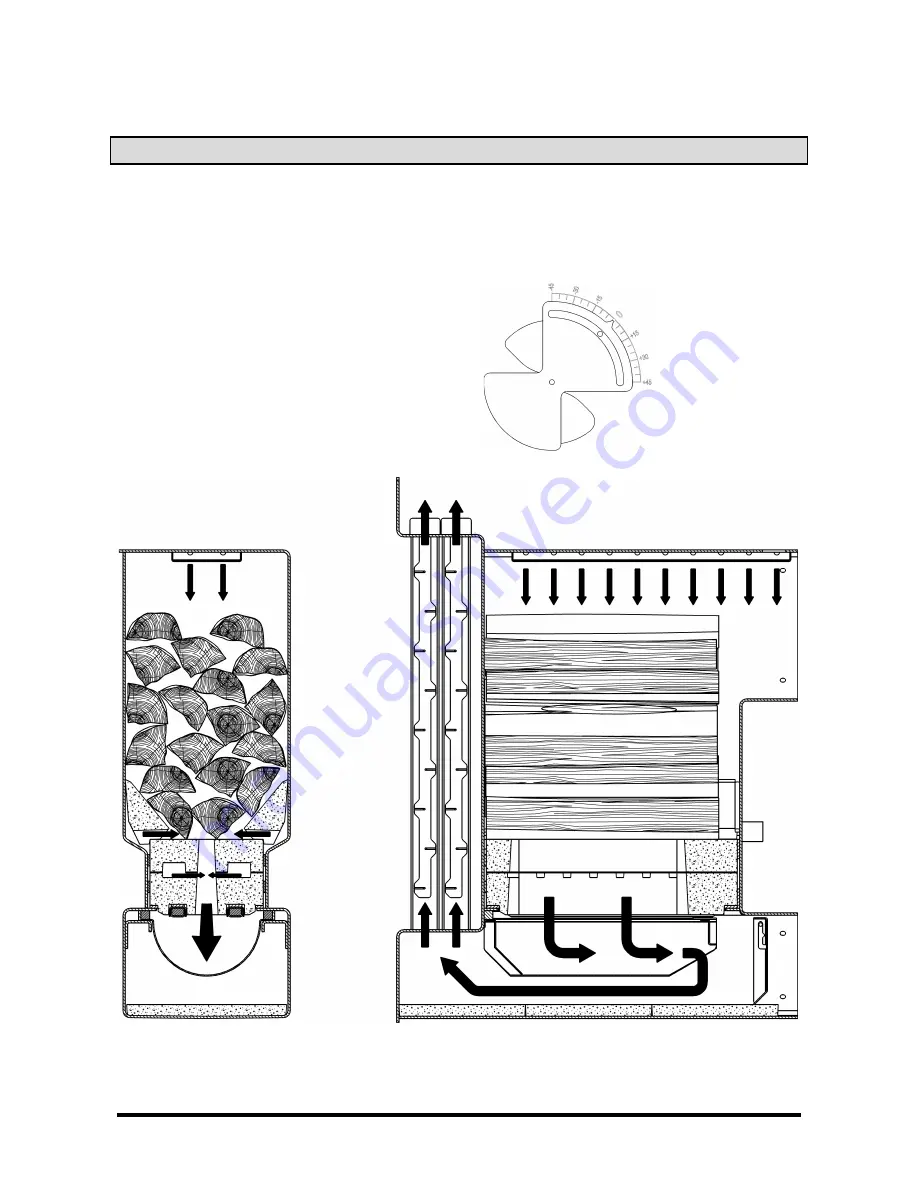

Combustion Air Control

For clean boiler convection surfaces, the flue

gas temperature should be approximately 170

ºC. Raising temperature by increasing power

will reduce the boiler efficiency. Too low

power should not be used either as this will

drop the flue gas temperature below 150 ºC

due to corrosion hazard.

The required air quantity and ratio for burning

varies depending on the wood to be burnt.

Primary and secondary air is factory adjusted

for birch firewood.

Upper primary air does not have to be ad-

justed under normal operating conditions.

Lower primary air should be adjusted when

the boiler power needs to be changed. The

boiler power grows in correlation with the

flame length.

Secondary air can be adjusted when the boiler

water temperature has been unchanged for 45

minutes after the beginning of combustion.

Upper

primary air

Lower primary

air

Lower seconda-

ry air