11

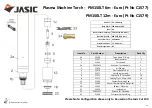

Plasma Machine Torch

-

PM150LT 6m

-

Euro (Pt No C1577)

PM150LT 12m

-

Euro (Pt No C1579)

Current :

50

-

150 Amps

Duty Cycle :

150 Amps at 60%

Gas :

Air

Gas Pressure

-

Cutting :

72

-

87 PSI (5.0

-

6.0 bar)

Gas Flow @ 125A :

466 SCFH (220 lpm)

Post Flow Time :

45 Seconds

Pilot Arc Current :

15

-

22 Amps

Pilot Arc Ignition :

HF

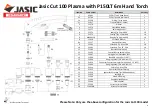

Please Note: Configuration above only to be used on the Jasic Cut 100

Wilkinson Star Technical

Item No

Part Number

Description

Pack Qty

1b

C1398

Torch Head

‘

O

’

Ring

1

1c

C1017

Front Insulator

1

2

C1354

Torch Head

1

2a

C3055623

Machine Torch Handle

1

3

C1378

Air Diffuser

1

4

C1376

Electrode Hafnium

5

5

C1377

Swirl Ring (Vespel)

1

6

C1371

Cutting Tip (1.1mm) 60A

10

6

C1372

Cutting Tip (1.35mm) 90A

10

12

C1393

Contact Retaining Cap

1

12

C1006

Contact Retaining Cap (Long Life)

1

18

C1012

Spacer

-

Machine

1

22

C1016

Locking Nut

1

23

C3045012

Wrench for Electrode

1

24

C1509

Extractor for Swirl Ring

1