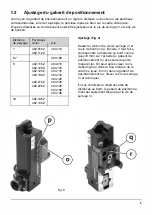

1.2

Setting the depth stop (f)

In order to set the depth stop (f) we recommend dispensing several test screws. First of all

the depth gauge must be set to the corresponding clearance x (Diagram 1 ).

450.007 /008:

x

=

7,3 mm= 8 notches

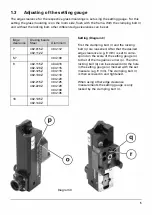

lf the following results occur, the equipment should be adjusted as indicated:

a) The screw threads are stripped or the screwdriver blades break frequently, or the Philips

heads an the screws ar damaged. The depth stop (f) is set too far to the rear. Correct this

by turning the sdjustment screw (f) in a clockwise direction (Diagram 2). (The equipment

should be in the operating position.)

b) The screw flange is not seated flush with the steel tube. The depth stop (f) is set too far to

the front. Correct this by turning the adjustment screw (f) in a counter-clockwise direction.

(The equipment should be in the operating position.)

4

-

--

-

-

Diagram 1

Diagram 2