18

TO ENTER sElF-DiAgNOsTiC MODE:

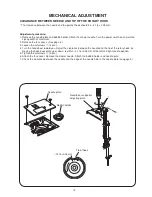

Preparation:

1. Turn the power switch off.

2. Move the bobbin winder spindle to the left.

3. Raise the feed dog.

4. Set the speed control lever to the left.

5. Remove the presser foot and raise the presser foot lifter.

6. Turn the hand wheel toward you to raise the needle to its highest position.

NOTE:

• Be careful: the sewing machine may start running in its own while in test mode.

• Turn off the power switch before replacing any parts.

• Repeat the diagnostic test until the problem has been resolved.

• You can skip steps in the diagnostic procedure and go directly to the test you want to perform.

(Enter self-diagnostic mode, then select the step number of the diagnostic test you require by pressing the

start/stop button.)

To begin:

Turn on the switch. If any of the following problems occur, take the recommended actions in the order they

are shown.

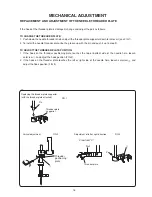

1. The machine does not respond when the power switch is turned on:

• Check each connector connection

• Replace the machine socket

• Replace the switching regulator

• Replace the printed circuit board A

2. The sewing machine lamp does not light up:

• Replace the light bulb

• Replace the printed circuit board A

sElF-DiAgNOsTiC TEsT

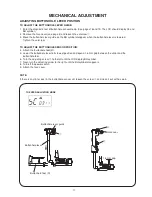

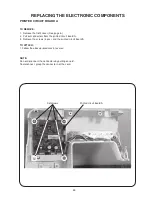

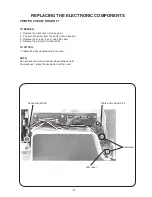

1. Turn the power switch on while

simultaneously pressing auto-lock

button and needle up/down button.

2. The LCD display

will indicate “01”.

3. Press the start/stop

button to enter the

self-diagnostic mode.