12

MECHANICAL ADJUSTMENT

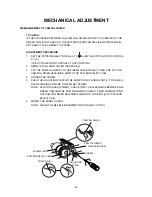

CLEARANCE BETWEEN NEEDLE AND HOOK (ADJUSTMENT METHOD NO. 1)

TO CHECK:

THE CLEARANCE BETWEEN THE NEEDLE AND SHUTTLE RACE SHOULD BE –0.05 TO

+0.10 MM.

IF NOT, ADJUST AS FOLLOWS:

ADJUSTMENT PROCEDURE:

1.

REMOVE THE TOP COVER (SEE PAGE 4).

2.

SET THE PATTERN SELECTOR DIAL AT ( ), STITCH WIDTH CONTROL AT ( 0 ).

3.

LOOSEN SETSCREW (A), AND MOVE THE NEEDLE BAR SUPPORTER IN THE

DIRECTION OF THE ARROWS TO GET A CLEARANCE BETWEEN –0.05 TO +0.10 MM.

* IF CLEARANCE IS TOO WIDE, MOVE THE NEEDLE BAR SUPPORTER TO

DIRECTION (B).

* IF CLEARANCE IS TOO NARROW, MOVE THE NEEDLE BAR SUPPORTER TO

DIRECTION (C).

NOTE: AFTER THIS ADJUSTMENT, CHECK IF THE CLEARANCE BETWEEN THE

NEEDLE AND NEEDLE PLATE IS MORE THAN 0.15 MM AS SHOWN IN FIGURE

(D). IF NOT, ADJUST THE CLEARANCE BETWEEN NEEDLE AND SHUTTLE

RACE BY ADJUSTMENT METHOD (2), AFTER RE-ADJUSTMENT CHECK THE

CLEARANCE BETWEEN NEEDLE AND NEEDLE PLATE AGAIN.

4.

ATTACH THE TOP COVER.

SETSCREW (A)

DIRECTION (C)

DIRECTION (B)

NEEDLE BAR SUPPOTER

–0.05 TO +0.10MM

FIGURE (D)

CLEARANCE BETWEEN NEEDLE

AND NEEDLE PLATE IS MORE

THAN 0.15MM.

Содержание 415

Страница 1: ...SERVICING MANUAL 419S 423S 415...

Страница 26: ...24 WIRING FOR 110 120V FROM LAMP SOCKET FROM MOTOR FROM MOTOR FROM LAMP SOCKET FOR 220 240V...

Страница 27: ...PARTS LIST MODEL 423S 419S...

Страница 34: ...PARTS LIST 1 2 3 4 5 8 8 7 6 6 9 10 11 12 13 14 15 16 17 18 19 20 21 22 7...

Страница 38: ...PARTS LIST 1 7 8 9 11 4 12 13 14 10 2 3 4 4 5 6 4 4 4 15 16 17 10 18 19 20 21 22 11...

Страница 40: ...PARTS LIST 26 19 3 5 12 7 1 2 4 6 8 9 11 10 13 14 15 16 17 18 16 20 21 22 23 24 25 27 28 29 18 32 30 8 31 13...

Страница 42: ...PARTS LIST 1 2 3 4 5 6 7 8 9 10 15...

Страница 44: ...PARTS LIST 1 2 3 4 5 6 7 8 9 10 11 12 13 17...