Page 14

ENGLISH

Jandy

®

Variable-Speed Pumps

|

Installation & Operation Manual

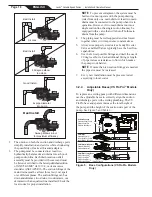

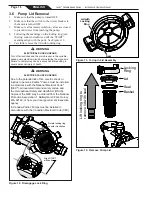

An access cover with Phillips-head screw must be

removed before proceeding.

Auxiliary Load Connection Requirements

WARNING

ELECTRICAL SHOCK HAZARD

Due to the potential risk of fire, electric shock, or

injuries to persons, Zodiac

®

Pumps and any auxiliary

loads must be installed in accordance with the

National Electrical Code

®

(NEC

®

), all local electrical

and safety codes, and the Occupational Safety and

Health Act (OSHA). Copies of the NEC may be

ordered from the National Protection Association, 1

Batterymarch Park, Quincy, MA 02169, or from your

local government inspection agency.

In Canada, Zodiac Pumps must be installed in

accordance with the Canadian Electrical Code

(CEC).

• The Auxiliary Load relay contacts are rated

at 230V/115V, 11A RMS. Please ensure the

requirements of the equipment to be connected to

the Auxiliary Load

do not exceed this rating

.

3.5.1

Auxiliary Relay Operation

Characteristics

Auxiliary Relay contact activation is speed dependent.

Auxiliary Relay 1 has an activation speed of 1725 RPM

and Auxiliary Relay 2 has an activation speed of 2250

RPM.

3.5.2

Contact Closure

From a stopped condition, there is a three-minute delay

before the Auxiliary Relay contact is closed when the

motor speed reaches and maintains the activation speed.

Once the three minute run time criteria has been reached,

when going from an RPM below the activation speed to

an RPM above the activation speed, there is a 5-second

delay before the Auxiliary Relay contact is closed.

3.5.3

Contact Opening

When going from an RPM above the activation speed to

an RPM below the activation speed, the relay opening is

always immediate.

3.5.4

Dry Contact Operation

Dry contacts can be used as a controller if a Zodiac

controller is not connected to the RS-485 line. By

jumping one of the inputs to common, it will turn on

the pump, prime, and go to a pre-determined speed

indefinitely until the short is broken (See Figure 10 &

11). If no inputs are jumped to common, the RPM is

zero. These speed settings cannot be changed unless

a Zodiac controller is connected. When any Zodiac

controller is connected through RS-485, all dry contact

commands will be ignored.

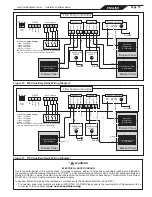

BLACK

YELLOW

RED

GREEN

RS485

4 3 2 1

RED

BLACK

YELLOW

GREEN

REMOTE CONTROL

5 4 3 2 1

INPUT

2

INPUT

3

INPUT

4

COMMON

INPUT

1

2-Position

DIP Switch

1- 3/8” Threaded

2- 3/4” Threadless

3- 1/2” Threadless

4- 1/2” Threaded

Bonding Lug

Controller

(Rear View)

RS485

Cable

(22 A

WG)

1

2

3

4

4 3 2 1

BLACK

YELLOW

RED

GREEN

Figure 9. Wiring to a Controller

3.4 Pump DIP Switch Settings

The motor is equipped with an auto sensing power

circuit which illiminates the need for DIP switches

1 and 2. As shown in Figures 9, the 2-position DIP

switch serves the function of pump addressing when

using multiple pumps. If the pump is connected to a

JEP-R controller or iQpump01, DIP switches 3 and 4

must remain in the OFF position. If connecting to an

automation system that supports multiple pumps, use

the DIP switches (See Table 3) to set the address for the

pump and refer to the automation system's manual for

additional instructions.

NOTE

DIP switches 3 and 4 must only be used if your

Zodiac

®

Automation system does NOT have RS-485

auto-addressing capabilities.

Switch 3 Switch 4 Pump Address

OFF

OFF

PUMP 1 (Factory Default)

ON

OFF

PUMP 2

OFF

ON

PUMP 3

ON

ON

PUMP 4

Table 3. DIP Switch Settings

3.5 Auxiliary Relay Operation

Jandy pump model numbers ending with "2A" are

equipped with a terminal bar that provides user access to

two built-in Auxiliary Relays. The normally-open relays

are activated under certain operating conditions and

are intended to be used to control external devices that

require system water flow for proper functioning, such

as booster pumps, salt water chlorinators, etc.

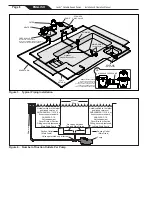

See Figures 10 and 11 for compartment’s location

details.