GB-23

RANSOMES MASTIFF 91

SAFETY, OPERATORS, MAINTENANCE AND PARTS MANUAL

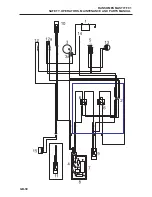

Fig.32

Fig.33

Fig.34

ADJUSTMENTS

Read the safety instructions

HEIGHT OF CUT ADJUSTMENT

The cutting height is determined by the position of

the front rolls in relation to the bottom blade;

variation of this setting is made by adjusting the

front roll:

1.

Loosen the bolts (Fig. 32) securing the front

roll brackets on both sides of the machine.

2.

Set the roll at the required height - raise the

height of cut by lowering the front roll and

reverse the procedure to reduce the height

of cut. Check that the setting is the same at

both sides of the machine.

3.

Tighten the bolts.

NOTE: The front roll should never be set so that

the bottom blade is pressing on the turf; this will

damage the spiral cutters, bottom blade and the

turf.

HANDLE (PEDESTRIAN MACHINE

ONLY)

The height of the handle can be adjusted to suit

the operator. Always raise the handle when fitting

and using the trailing seat to give clearance for

legs over undulating ground.

To adjust:

1.

Slacken the clamp bolts (Fig. 33)

2.

Move the handle to the required height.

3.

Re-tighten the bolts.

CYLINDER TO BOTTOM BLADE

ADJUSTMENT

To check that the cutting cylinder is set correctly to

the bottom blade: tilt the machine back, hold a thin

piece of paper between the edge of the blade and

spiral cutters, and turn the cylinder manually.

The paper should be cut cleanly along the length

of the bottom blade; if not, some adjustment is

necessary, DO NOT OVERTIGHTEN.

Adjustment is made by turning the adjustment

screws (Fig. 34) clockwise to move the cylinder

towards the blade.

It is recommended that an 1/8 of turn is made

alternatively to each screw, checking frequently

with the paper until the correct setting is achieved.

Содержание LDEA130

Страница 2: ...2003 Ransomes Jacobsen Limited All Rights Reserved...

Страница 32: ...GB 30 RANSOMES MASTIFF 91 SAFETY OPERATORS MAINTENANCE AND PARTS MANUAL...

Страница 68: ...Parts 2 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 1 CUTTING UNIT...

Страница 70: ...Parts 4 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 1 CUTTING UNIT...

Страница 72: ...Parts 6 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 2 FRONT ROLL SIDE ROLLS...

Страница 74: ...Parts 8 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 2 FRONT ROLL SIDE ROLLS...

Страница 86: ...Parts 20 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 6 GEAR BOX FINAL DRIVE...

Страница 88: ...Parts 22 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 6 GEAR BOX FINAL DRIVE...

Страница 90: ...Parts 24 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 6 GEAR BOX FINAL DRIVE...

Страница 92: ...Parts 26 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 7 LANDROLLS BRAKE...

Страница 94: ...Parts 28 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 7 LANDROLLS BRAKE...

Страница 96: ...Parts 30 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 8 GRASSBOX...

Страница 100: ...Parts 34 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10a Grooved Front Roll...

Страница 102: ...Parts 36 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10b Trailing Seat 26...

Страница 104: ...Parts 38 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10c Steering Seat...

Страница 106: ...Parts 40 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10c Steering Seat...

Страница 108: ...Parts 42 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10c Steering Seat...

Страница 110: ...Parts 44 RANSOMES MASTIFF 91 Series BY CJ SAFETY OPERATION MAINTENANCE AND PARTS MANUAL 10d Groomer Kit...

Страница 117: ......