10 MAINTENANCE & LUBRICATION CHARTS

28

10

MAINTENANCE & LUBRICATION CHARTS

10.1 GENERAL ________________________________________________________________

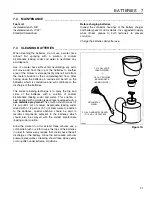

The mower was designed for minimum lubrication. Over

greasing will produce high loads on the bearings;

thereby reducing the performance of the machine.

All maintenance intervals must be performed more

frequently when operating in extremely dusty conditions.

1.

Always clean grease fittings before and after lubrication.

2.

Lubricate with grease that meets or exceeds NLGI

Grade 2 LB specifications. Apply grease with a

manual grease gun and fill slowly until grease

begins to seep out. Do not use compressed air.

3.

For smooth operation of pivot points and other

friction points, apply several drops of SAE 30 oil

every 50 hours or as required.

4.

To lubricate point

(L4)

, remove L.H. transport wheel

and mounting bracket

(E)

to gain access to fitting.

Turn the traction drum if pulley

(F)

is blocking the

fitting then insert grease gun through hole and

carefully apply grease.

5.

To lubricate points

(L7)

, remove transport wheel,

nut

(A)

from end of shaft and pull wheel hub

(D)

off.

Remove collar

(B)

and bushing

(C)

then pack

bearing with lithium grease.

10.2 MAINTENANCE CHART ____________________________________________________

A - Adjust C - Clean I - Inspect L- Lubricate R - Replace AR - As Required

* Indicates initial service for new machines.

I

Manual grease gun with NLGI Grade 2 (Service Class LB).

WARNING

Before you clean, adjust, or repair this equipment,

disengage all drives, engage parking brake, turn power

off and disconnect power connector to prevent injuries.

!

!

Recommended Service and Lubrication Intervals

Every

3-4

Hours

Every

20

Hours

Every

50

Hours

Every

100

Hours

Every

250

Hours

Yearly

Lubricant

Type

Charge Batteries

AR

I

C

Belt Tension

I-A

Grease Locations

L1 - L5

L

L

I

L6-L7

L

I

Содержание E-Walk 62290

Страница 1: ...Technical Manual GB E Walk 62290 22 11 Blade Reel 4105380 Rev A...

Страница 30: ...11 NOTES 30 11 NOTES...

Страница 61: ...61 INDEX...