GB-5

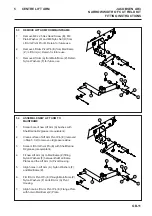

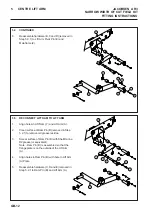

JACOBSEN AR3

NARROW WIDTH OF CUT FIELD KIT

FITTING INSTRUCTIONS

•

Release blockages with care. Keep all parts

of the body away from the cutting edge.

Beware of energy in the drive which can

cause rotation when the blockage is released.

•

Keep other people away from the cutting units

as rotation of one cylinder can cause the

others to rotate.

2.9

ADJUSTMENTS, LUBRICATION AND

MAINTENANCE

•

Stop the engine and make sure all moving

parts are stationary.

•

Apply brakes and disengage all drives.

•

Read all the appropriate servicing instructions.

•

Use only the replacement parts supplied by

the original manufacturer.

•

When adjusting the cutting cylinders take

care not to get hands and feet trapped when

rotating cylinders.

•

Make sure that other people are not touching

any cutting units, as rotation of one cylinder

can cause the others to rotate.

•

To reduce the fire hazard, keep the engine,

silencer and battery compartments free of

grass, leaves or excessive grease.

•

Replace worn or damaged parts for safety.

•

When working underneath lifted parts or

machines, make sure adequate support Is

provided.

•

Do not dismantle the machine without

releasing or restraining forces which can

cause parts to move suddenly.

DANGER - Indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING - Indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION - Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor

or moderate injury and property damage. It may

also be used to alert against unsafe practices.

2

SAFETY INSTRUCTIONS

Содержание AR3

Страница 2: ...2005 Ransomes Jacobsen Limited All Rights Reserved...

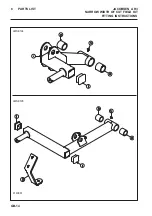

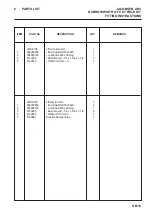

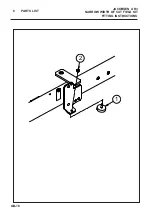

Страница 14: ...GB 14 JACOBSEN AR3 NARROW WIDTH OF CUT FIELD KIT FITTING INSTRUCTIONS 6 PARTS LIST LMSE194 LMSE195 4140881...

Страница 16: ...GB 16 JACOBSEN AR3 NARROW WIDTH OF CUT FIELD KIT FITTING INSTRUCTIONS 6 PARTS LIST 2 1...

Страница 18: ...GB 18 JACOBSEN AR3 NARROW WIDTH OF CUT FIELD KIT FITTING INSTRUCTIONS 7 NOTES...

Страница 19: ......