1/8

g

Please read this manual carefully, also with related manual for the machinery before

use the controller.

g

For installing and operating the controller properly and safely, qualified engineers

are required.

g

Please stay away from arc welding equipment, in order to avoid electromagnetic

interference and malfunction of the controller.

g

Keep room temperature bellow 45°c and above 0°c

g

Do not use in humidity below 30% or above 95% or dew and mist places.

g

Please turn off the power and unplug the power cord, before install the control box

and other components,

g

To prevent interference or electric leakage accidents, please make the ground work;

the power cord ground wire must be securely connected to earth by an effective

way.

g

All parts for the repair provided by the Company or approved before use.

g

Please turn off the power and unplug the power cord before any maintenance

action. There is dangerous high voltage control box, you must turn the power off

after one minute before opening the control box.

g

The symbol

in this manual means Safety Precautions, please pay attention to it

and strictly follow it, to avoid any unnecessary damage.

K4 Operation Manual

1 Installation Instructions

1.1 Product specifications

Product Type

AHE59

Supply Voltage

AC 220 ±

V

Power frequency

50Hz/60Hz

Maximum output power

550W

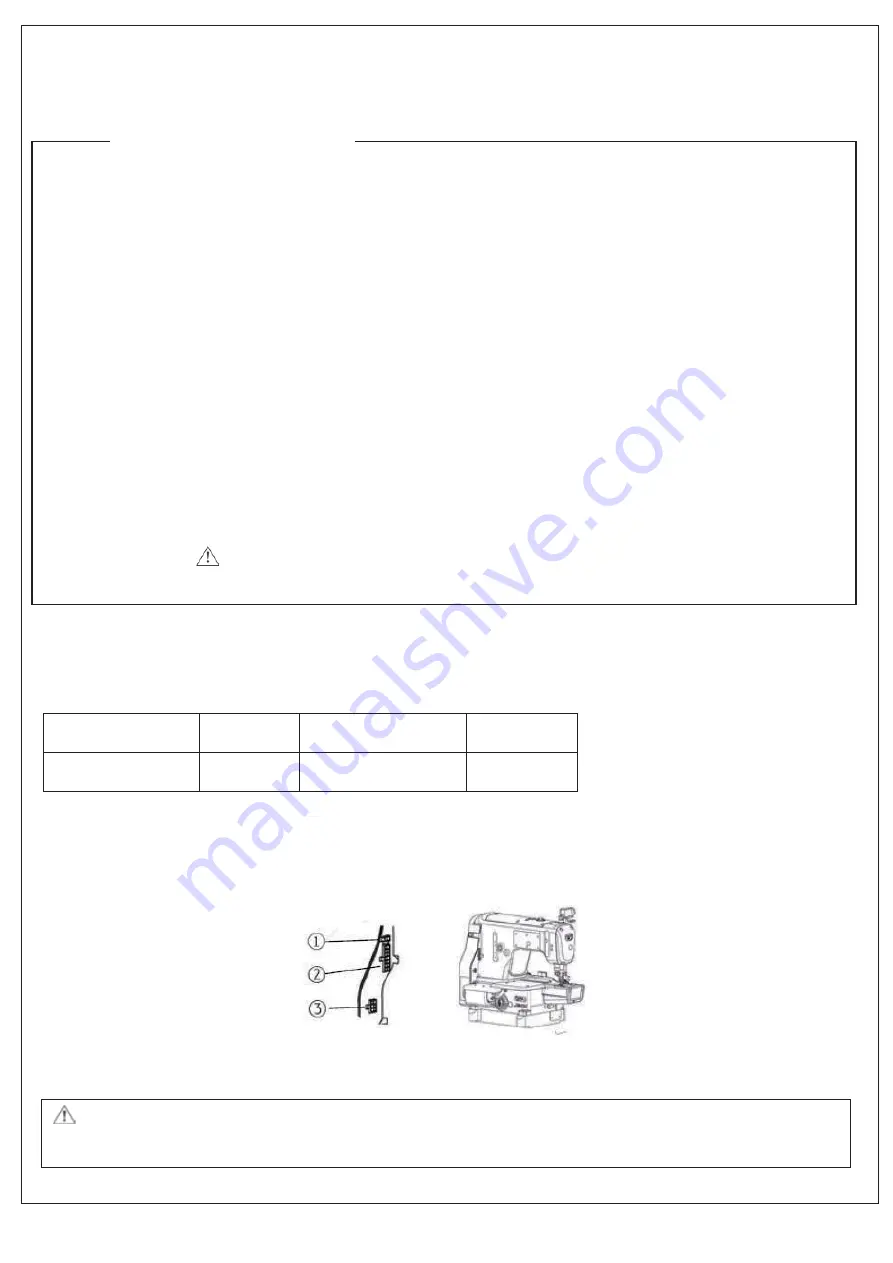

1.2 Interface plug connections

Connecting the plugs of pedaland machine head to the corresponding sockets at the back of controller, as

Figure 1-2. Please check and confirm the plug is inserted firmly.

Fig.1-1 Controller Socket Diagram

ķ

Presser Foot lifter solenoid socket;

ʓ

Solenoid socket ;

ʔ

Pedal socket;

喚

If it is difficult toinserted plug into socket, please check whether them are matching with each other, or the inserting direction

or needle insertion direction is correct!

Safety Instruction

Содержание JK-K4-UT

Страница 1: ......

Страница 2: ...0 51 1 1 YKXOKY YK SGT GR...

Страница 22: ...20 51...

Страница 36: ...34 51 YKZ YIXK IXGTQ JOYQ JXO K IUTTKIZOTM XUJ T Z T Z...

Страница 40: ...38 51 Moving cutter is parallel to the fixed cutter Screw1 Screw3 Screw4 Screw2 Fixed cutter...

Страница 41: ...39 51 JP YZ IROV GTJ VXKYY XK YNKKZ clip Pressure sheet clip is parallel to the fixed cutter...

Страница 47: ...45 51...

Страница 48: ...46 51 SS...

Страница 50: ...48 51...

Страница 52: ...50 51...

Страница 53: ...f 9 g g g g g g g g g g...

Страница 54: ...1 11 2 12 13 14 15 16 17 8 8 8 8 8 8 8 8...

Страница 55: ...3S...

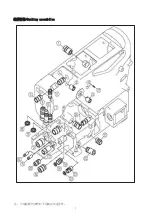

Страница 68: ...XVKLQJ DVVHPEOLHV...

Страница 70: ...UDPH DVVHPEOLHV...

Страница 72: ...RYHU DVVHPEOLHV...

Страница 74: ...ORWK SODWH DVVHPEOLHV...

Страница 76: ...RRN VKDIW DVVHPEOLHV...

Страница 78: ...0DLQ VKDIW DVVHVPEOLHV...

Страница 80: ...1HHGOH EDU DVVHPEOLHV...

Страница 82: ...1HHGOH JXDUG DVVHPEOLHV...

Страница 84: ...HHG PHFKDQLVP...

Страница 86: ...1HHG PHFKDQLVP...

Страница 88: ...3UHVVHU IRUP DVVHPEOLHV...

Страница 90: ...1HHGOH IHHGLQJ DVVHPEOLHV...

Страница 92: ...7KUHDG ORRVLQJ DVVHPEOLHV RQH...

Страница 94: ...7KUHDG ORRVLQJ DVVHPEOLHV WZR...

Страница 96: ...7KUHDG ORRVLQJ DVVHPEOLHV...

Страница 98: ...DP DVVHVEOLHV...

Страница 100: ...XEULFDWULRQ DVVHPEOLHV...

Страница 102: ...2LO SXPS DVVHPEOLHV...

Страница 104: ...6LOLFRQ RLO GHOLFH DVVHPEOLHV...

Страница 106: ...DXJH VHW VSHFLILF SDUWV...

Страница 108: ...QLIH KROGHU DVVHPEOLHV...

Страница 111: ...7RS ZLSHU DVVHPEOLHV...

Страница 113: ...6ROHQRLG DVVHPEOLHV...

Страница 115: ...OHFWURQLF FRQWURO DVVHPEOLHV...

Страница 117: ...IWHU FDP DVVHPEOLHV...

Страница 120: ...IWHU ILJKW FDP DVVHPEOLHV...

Страница 122: ...7KUHDG SRRO VVHPEOLHV...

Страница 124: ...35AC 35ACFT device...

Страница 126: ...35AC 35ACFT device...

Страница 128: ...FFHVVRULHV DVVHPEOLHV...

Страница 130: ...HGSODWH DVVHPEOLHV...