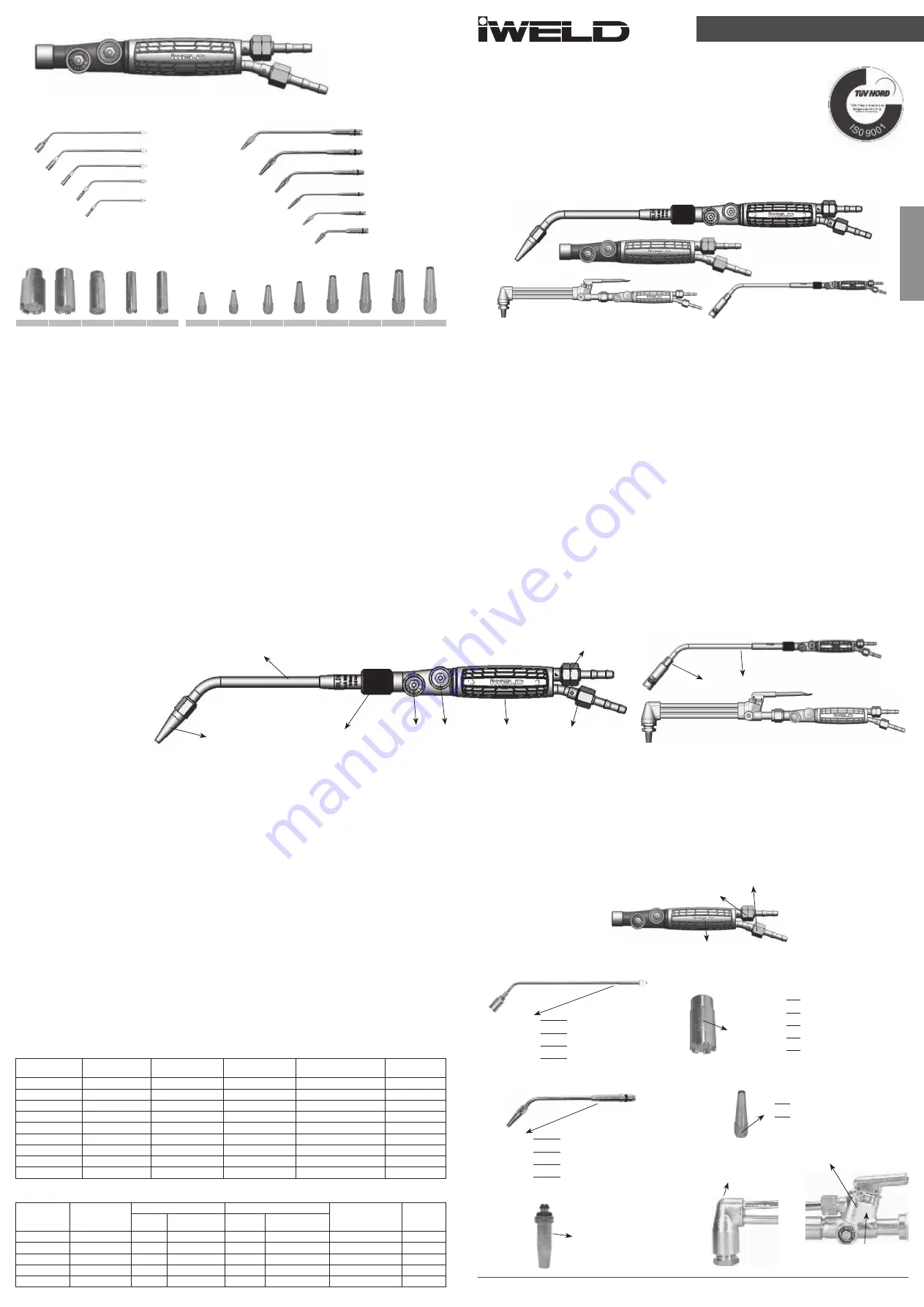

4 - Shank and Attachments

5IK302601

IWELD KOMBI 30 shank

Heating Attachments

Welding Attachments

Heating Nozzles

Welding Nozzles

5 - Frequent malfunctions

• Loose connection nut

- Loose connection nut (6) will not insure proper gas aspiration therefore the flashback danger will be

high.

• Incorrect nozzle selection for welding, cutting or heating process.

As a result of applying incorrect nozzle for welding, heating or cutting the flame will not be stable dur

-

ing the process. Choose the proper nozzle size always!

6 - Maintenance

• Repair and maintenance should be done by trained and authorized technician. Only original spare

parts should be used for repair. Producer declines all liability for damages, accidents caused by un

-

professional repairs.

• Torches must be controlled periodically. If any part, valves, nipples etc. are leaking, damaged or

simply are dirty from oil, the use of the equipment is strictly prohibited! Send the device to authorized

service partner for repair or inspection.

• Should you notice any internal or external leakage at the shank valves, at the nipples and nuts then

the gas supply must be closed immediately! Never retry to use the leaking components prior any pro

-

fessional inspection!

7 - Storing and transportation

• To protect your device from any possible damage during transportation store it always in its original

box.

• Shall you store your equipment for long time please make sure that all components are clean, and

dry. The storage area must be dry, clean and safe from dust sources.

8 - Cautions

• There shouldn’t be done any changes on torches without our company’s control and information.

• Improper use of the cutting torches may cause serious damages. They should be used by trained

staff only.

• Torches must be protected from accidentally crashes, falls, oil and another dirt sources.

• Torches and their attachments should be used respecting the markings.

• Attachments and nozzles on the heating and welding process must be selected according to in

needed heat values as shown in Table-1 and Table-2.

9 - Installation

• Welding attachment or heating attachment’s connection nut (6) must be screwed on the shank

tightly.

• As Regards of changing nozzles on welding attachment and heating attachment, welding or heat

-

ing nozzle (8-10) that are picked considering Table-1 or Table-2 must be installed to welding or heating

attacments (7-9) by using suitable wrench.

• Gas hose ( Ø6 mm) must be connected to installed welding or heating attachment hose connection

by using clip according to equipment which is used.

• When using welding, heating and cutting torches, flashback arresters must be used between hose or

flachback arrester that is suitable to torch on the system must be used.

Due to welding, heating and cutting torches are working with vacuum principle, shank

connection nut (6) must not be loose!

10 - Technical information tables

Table-1 Welding Attachments and Nozzles

Welding Nozzle

Order No.

Welding Attach

-

ment Order No.

Welding Capacity

Oxygene Pressure

and consumption

Acetylene Consumption

Heat Value

5IKVRG2010

5IK303610

0.2 -0.5 mm

2,5 bar - 85 (l/h)

0,25-0,35 bar - 85 (l/h)

8026 kj/h

5IKVRG2011

5IK303611

0.5 - 1 mm

2,5 bar - 95 (l/h)

0,25-0,35 bar - 105 (l/h)

9915 kj/h

5IKVRG2012

5IK303612

1 - 2 mm

2,5 bar -105 (l/h)

0,25-0,35 bar - 127 (l/h)

11992 kj/h

5IKVRG2013

5IK303613

2 - 4 mm

2,5 bar -125 (l/h)

0,25-0,35 bar - 150 (l/h)

14164 kj/h

5IKVRG2014

5IK303614

4 - 6 mm

2,5 bar -160 (l/h)

0,25-0,35 bar - 230 (l/h)

21718 kj/h

5IKVRG2015

5IK303615

6 - 9 mm

2,5 bar -220 (l/h)

0,25-0,35 bar - 280 (l/h)

26440 kj/h

5IKVRG2016

5IK303616

9 - 14 mm

2,5 bar -280 (l/h)

0,25-0,35 bar - 385 (l/h)

36355 kj/h

5IKVRG2017

5IK303617

14 - 20 mm

2,5 bar -390 (l/h)

0,25-0,35 bar - 500 (l/h)

47215 kj/h

5IKVRG2018

5IK303618

20 - 30 mm

2,5 bar -435 (l/h)

0,25-0,35 bar - 610 (l/h)

57602 kj/h

Table-2 Heating Attachments and Nozzles

Heating

Nozzle

Art. No.

Heating Attach

-

ment

Order No.

Oxygene

Propane (LPG)

Heat Value

Attach.

Lenght

Pressure

Consumption

Pressure

Consumption

87694721H

5IK303701

1-2 bar

4000-7000 l/h

0.5 bar

1000-2000 l/h

93700-187395 kj/h

420 mm

87694732H

5IK303702

1-2 bar

5900-12800 l/h

0.5 bar

1500-3200 l/h

93700-187395 kj/h

420 mm

87694743H

5IK303703

1-2 bar

8500-22900 l/h

0.5 bar

2200-5700 l/h

205890-534000 kj/h

490 mm

87694754H

5IK303704

1-2 bar

14200-28400 l/h 0.5 bar

3600-7100 l/h

337400-663865 kj/h

600 mm

87694765H

5IK303705

1-2 bar

17000-39700 l/h 0.5 bar

4300 -100000 l/h

403360-936975 kj/h

670 mm

KOMBI

30

Cutting and Welding Sets and Attachments

INSTRUCTION MANUAL

The device should be used by trained person after regarding this manual only.

1 - Sets and their specifications

• Both welding, heating and cutting processes can be executed with the shank (IK302601).

• The system is designed and manufactured according to EN ISO 5172 standard.

Welding

• Welding attachments are designed ergonomically by forming different flame sizes for oxy-acetylene

welding processes in different industrial areas. Spare welding nozzles are available to reduce your

maintenece cost.

Heating

• Heating attachments are designed to form large flame sizes for heating, burning and melting pro

-

cesses for different industrial areas where high temperature is needed. Oxy-propane flame temp-

erature is reasonably higher than air-propane mixture flame temperature. Spare heating nozzles are

availables also.

Cutting

• The cutting attachment is designed to answer different industrial sector’s oxy-fuel cutting needs.

The cutter that is designed for both acetylene, propane and natural gas is a state of the art tool. The

cutting attachment is very safe, however you have to pay special attention to use the proper fuel gas

specific cutting nozzle.

2 - Application

• Set the gas pressures on the regulators for welding, cutting and heating as specified in Table1 and

Table 2. Calculate with some pressure drops at the flashback arrestors used in the gas supply system.

• Open smoothly first the Oxygen Valve (5) then gas mixture will flow to the enviroment by opening the

Fuel Gas Valve (4).

• Ignite the gas mixture flow at the welding nozzle, cutting nozzle or at the heating nozzle.

• Adjust the setup by turning smoothly into opening or closing direction both the Oxygen and Fuel Gas

Valves.

Turning off the device

• When the welding, heating or cutting process should be ended, close first the Fuel Gas Valve and

Oxygen Valve after.

3 - Marking

“ F “ Fuel Gas

“ O “ Oxygen

Heating

Cutting

IWELD

No:0 3610 A

0.2-0.5 mm

2,5 bar

Producer Identification Marking

Welding attachment No. And Gas Type

Welding Capacity

Operation Pressure

Cutting Thickness

Gas Pressures

Gas Type

Nozzle Size

Producers

Identification Mark

Production Date

Company Trademark

‘’ IWELD ‘’

0

Y

Nozzle No.

Producer Identification Marking

Trademark

“ IWELD “

Welding

IWELD

No: 1

OX 1-2 bar

PRO 1/2 bar

Producer Identification

Heating Attachment No.

Operation Pressure (oxygen)

Operation Pressure (Propane)

1- Shank

2- Oxygen Hose Connection

3- Fuel Gas Hose Connection

4- Fuel Gas Valve

5- Oxygen Valve

6- Welding or Heating

Attachment Connection Nut

7- Welding Attachment

8- Welding Nozzle

9 - Heating Attachment

10- Heating Nozzle

5IK303705

5IK303704

5IK303703

5IK303702

5IK303701

CUTTING EDGE WELDING

5IKVRG2010 5IKVRG2011 5IKVRG2012 5IKVRG2013 5IKVRG2014 5IKVRG2015 5IKVRG2016 5IKVRG2017

87694765H 87694754H 87694743H 87694732H 87694721H

IWELD

1H

P. 0.15-0.5 bar

O. 0.7-2.0 bar

PROP

A

NE

Producer Identification Mark

Nozzle No.

Propane Operation Pressure

Oxygene Operation Pressure

Gas Type

8

7

6

5

4

1

2

3

10

9

EN ISO 5172

ENGLISH

IWELD KFT.

2314 Halásztelek, II. Rákóczi Ferenc út 90/B

Tel: +36 24 532-625

Fax: +36 24 532-626

E-mail: [email protected]

www.iweld.hu

5IK303616

5IK303615

5IK303614

5IK303613

5IK303612

5IK303611