n

8

1. The suction pipe should employ the flooded suction method if possible. The shortest pipe possible, with

the minimum number of bends, should be designed. Arrange a proper support on the suction pipe so that

the load and the thermal stress of the pipe itself are not applied to the pump.

2. Attach the coupling on the suction pipe carefully, so that no air enters the line. The presence of air in the

suction pipe may prevent priming of the pump.

3. Avoid installations with poor suction conditions (e.g. vacuum in suction tank, large suction head or long

suction piping). NPSHa should always be at least 2 feet greater than NPSHr. For NPSHr values, refer to

the standard performance curve for your pump model or contact Iwaki Walchem or your distributor.

4. When using a bend on the suction side, install a straight pipe which is more than 20 inches long or 10

times as long as the suction port diameter before the suction port of the pump. Use the largest possible

radius of curvature for the bend.

5. Do not allow any projection where air may be trapped along the suction pipe. The suction pipe should

have an ascending gradient toward the pump.

n

Suction Piping

n

Piping

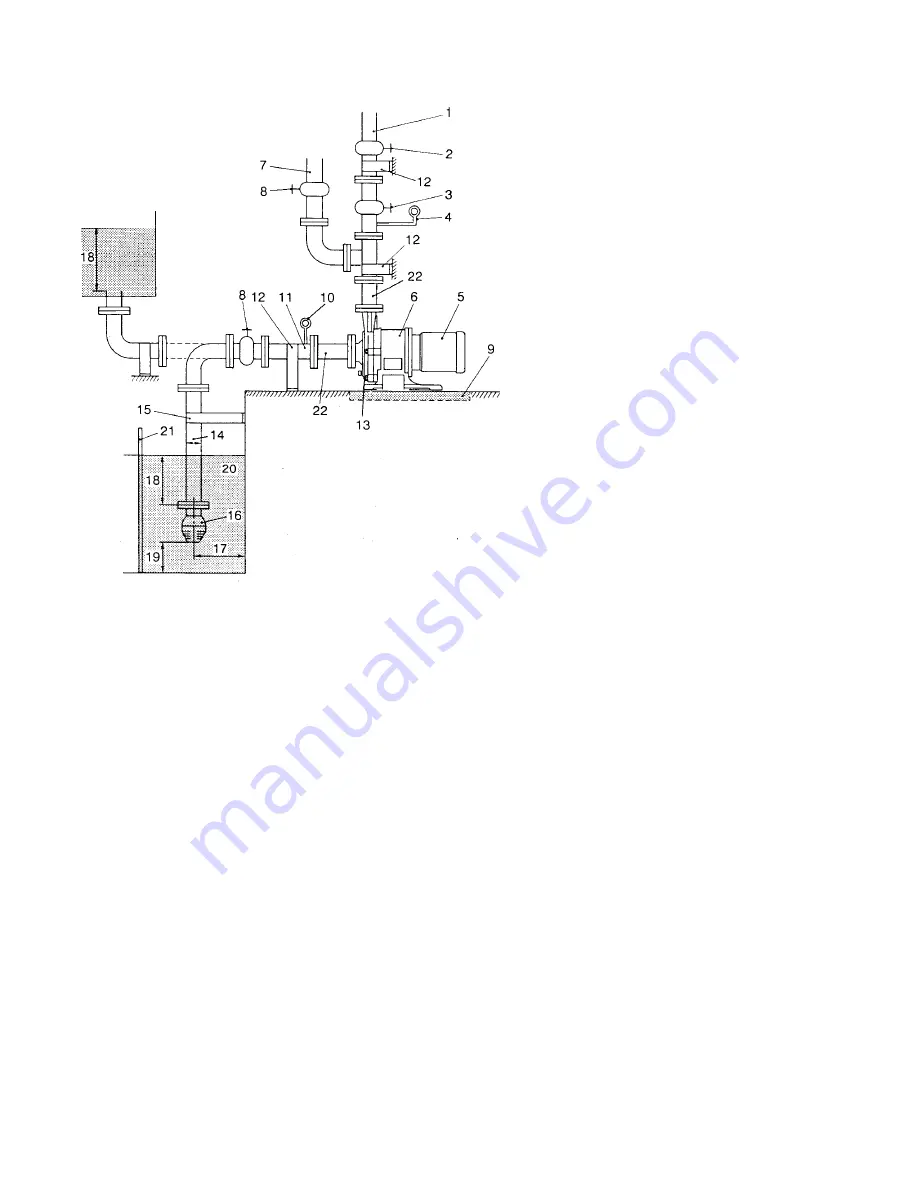

1. Discharge pipe (Use a support to keep the

pump free from the load of the pipe.)

2. Gate valve

3. Check valve

4. Pressure gauge

5. Motor

6. Pump

7. Priming pipe

8. Gate valve

9. Drain ditch

10. Compound gauge

11. Suction pipe (D=Diameter of pipe) (Shortest

horizontal section with an ascending gradient

toward the pump)

12. Pipe support

13. Pump drain (not applicable to MDH-(F))

14. Suction pipe (D=Diameter of pipe)

15. Suction pipe stabilizer brace (Used if the

suction pipe is particularly long.)

16. Foot valve

17. 1.5D or more

18.18 inches or more

19. 1- 1.5D or more (if sediment accumulates

easily)

20. Suction tank

21. Screen

22. Short pipe

Fig. 4