C78 ENT M50

INSTALLATION INSTRUCTIONS

7

FEBRUARY 2003 EDITION

FUEL LINE

charges. The tank shall be provided with a vent to prevent

internal pressure from exceeding ± 5kPa (± 0.5 mmH

2

O).

Fuel tank and suction assembly shall be so shaped as to

assure suction even at the maximum longitudinal and trans-

verse inclination allowed for the boat, with a residual quan-

tity of fuel oil considered “reserves”.

It is recommended to obtain a residual capacity on the bot-

tom of the tank, where the intake inlet should be posi-

tioned, and to use a Venturi inlet cup to prevent the entry

of sludge.The return flow must take place in such a way as

to favor the mixing of returning fuel oil with the fuel oil in

the tank.

Use of metallic pipes, except those made of copper or its

alloys, shall entail connecting each individual segment to the

engine ground or battery negative terminal to prevent the

accumulation of electrostatic discharges, and inserting a

vibration damping elastic junction on each segment.

Installed pipes shall be CE certified.

Pre-filter

The pre-filter with priming pump, supplied separate from

the engine, must be adequately fastened in such a way as to

enable easily to replace the filtering cartridge and/or to

operate the pump.

To avoid introducing impurities in the feeding pipelines

inside the engine, we recommend not installing filtering car-

tridges previously filled with fuel in the system.

Material Characteristics

The fuel tank, the suction and return assembly and the feed

pipes shall withstand the continuous abrasion caused by a

90 l/h flow of fuel oil at a temperature of 80 °C without

noticeable warping, wear, or release of material.

Use of metallic materials, though not copper alloys, is

allowed provided they are connected to the battery’s neg-

ative terminal to avoid the accumulation of electrostatic dis-

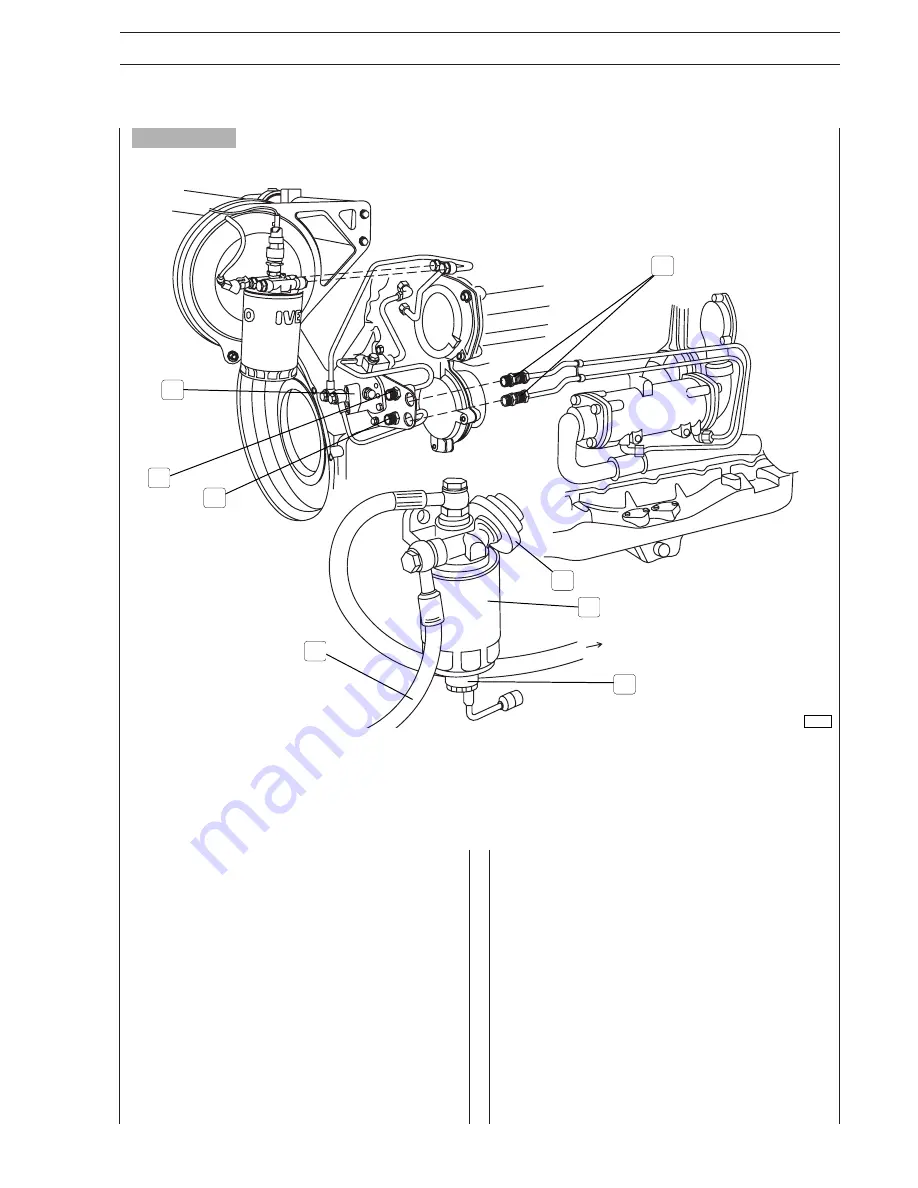

1. From the tank - 2. Sensor for detecting the presence of water in the filter - 3. Decanting filter - 4.Priming pump -

5. Fuel inlet junction - 6. Fuel return junction to tank - 7. Gear pump - 8. Junctions for inverter oil heat exchanger.

Figure 3

3

1

8

7

2

6

5

4

81795

Содержание C78 ENT M50

Страница 1: ...C78 ENT M50 MARINE ENGINE INSTALLATION INSTRUCTION ...

Страница 4: ...C78 ENT M50 IV FEBRUARY 2003 EDITION ...

Страница 6: ...C78 ENT M50 OVERVIEW 2 FEBRUARY 2003 EDITION ...

Страница 34: ...C78 ENT M50 DIAGNOSTICS 2 FEBRUARY 2003 EDITION ...

Страница 37: ...C78 ENT M50 5 FEBRUARY 2003 EDITION NOTES ...

Страница 38: ...C78 ENT M50 6 FEBRUARY 2003 EDITION NOTES ...

Страница 39: ...C78 ENT M50 7 FEBRUARY 2003 EDITION ...