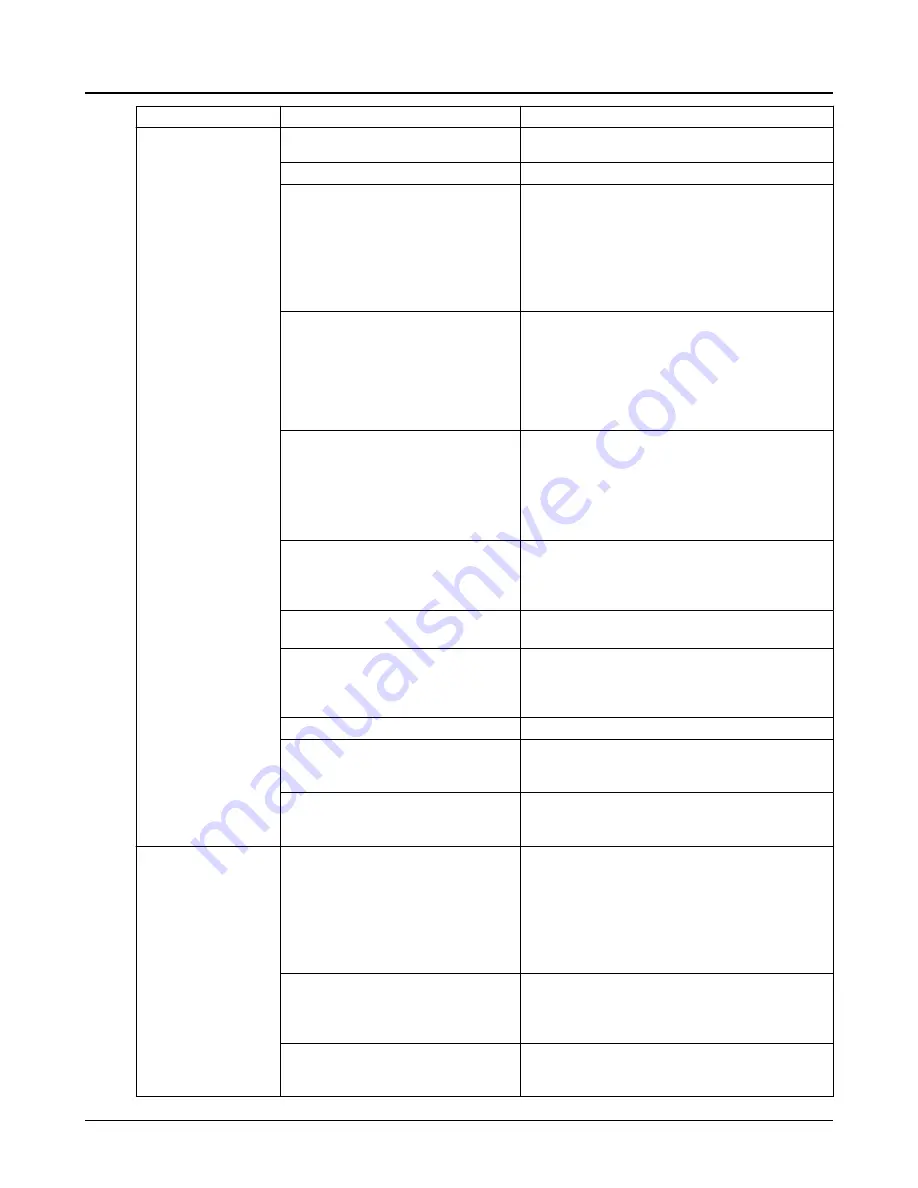

Symptom

Cause

Remedy

losses. Use a vacuum or compound gauge to

check the NPSH available.

The impeller is clogged.

Back-flush the pump in order to clean the impeller.

The amount of available NPSH is not

sufficient.

1.

Increase the positive suction head by low-

ering the pump or increasing the suction

pipe and fittings size.

2.

Sub-cool the suction piping at the inlet to

lower the temperature of liquid that is en-

tering the pump.

3.

Pressurize the suction vessel.

The impeller or wear rings are worn or

broken.

Inspect the impeller and wear rings and replace if

any of the following conditions are present:

•

The impeller or wear rings are damaged.

•

The vane sections are severely eroded.

•

The wear ring clearance is three times nor-

mal.

The foot valve is too small or partially

obstructed.

Check the valve and replace with the correct size if

necessary.

The openings of the valve ports must be 1–1.5

times as large as the suction pipe opening. If a

strainer is used, then the valve port openings must

be 3–4 times as large the suction pipe opening.

The suction inlet is not submersed

deep enough.

If the inlet cannot be lowered or if the problem per-

sists after the inlet is lowered, then chain a board

to the suction pipe. The board will be drawn into

the eddies and smother the vortex.

The shaft is rotating in the wrong direc-

tion.

Change the rotation. The rotation must match the

arrow on the bearing housing or pump casing.

The system static head is too high.

Check with ITT to determine whether a larger im-

peller can be used. If not, then you can cut pipe

losses, increase the speed, or both. Do not over-

load the driver.

The mechanical seal is worn or broken. Repair or replace the seal as necessary.

The liquid passages are obstructed.

Make sure that the suction and discharge valves

are fully open. Disassemble the pump and inspect

the passages and casing. Remove the obstruction.

Air or gases are trapped in the liquid.

Install a gas separation chamber on the suction

line near the pump and periodically exhaust the ac-

cumulated gas.

The pump starts and

then stops pumping.

The amount of available NPSH is not

sufficient.

1.

Increase the positive suction head by low-

ering the pump or increasing the suction

pipe and fittings size.

2.

Sub-cool the suction piping at the inlet to

lower the temperature of liquid that is en-

tering the pump.

3.

Pressurize the suction vessel.

The system static head is too high.

Check with ITT to determine whether a larger im-

peller can be used. If not, then cut pipe losses, in-

crease the speed, or both. Make sure to not over-

load the driver.

The system head or discharge head is

too high.

Check for pipe friction losses and that the valves

are wide open. The condition can be corrected with

larger piping.

7.1 Troubleshooting

60

Model 3409 Installation, Operation, and Maintenance Manual

Содержание Goulds Pumps 3409

Страница 1: ...Installation Operation and Maintenance Manual Model 3409 ...

Страница 2: ......