© Intatec Ltd 2017

14

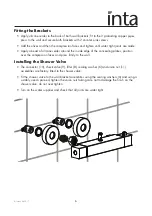

Fixed Riser Rail - Installation

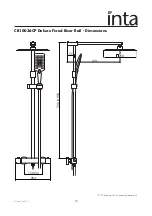

Fit the shower valve and finish tiling the wall prior to installing the shower riser.

Ensure the overhead arm projection does not exceed the shower tray.

Assemble the adjustment piece (6) into the top of the riser rail (1) ensuring both seals are fully

inserted.

Slide the handset holder (3) over the adjustment piece (6) and lock into position on the riser

rail (1).

Slide the adjustment bracket (4) over the adjustment piece and set to the required height.

Once the height has been set lock the bracket into place by tightening the grub screws (5)

using a suitably sized Allen key.

Locate the overhead shower arm (9) onto the adjustment piece (6) and the wall bracket (7) into

the overhead arm.

Fit the riser rail assembly to the shower valve and using a suitable method mark round the wall

bracket (7) onto the wall.

Remove the riser rail and wall bracket.

Position the wall bracket onto the wall within the markings and using the hole as a template,

drill a 6mm diameter hole.

If drilling into ceramic tiles use a ceramic bit.

To avoid cracking ensure the wall plug is pushed all the way behind the ceramic tile.

Using the screw provided secure the wall box firmly to the wall. This is the main fixing

screw for the riser and shower so must be held securely by the plastic plug in the wall.

If the wall is plaster board or soft building block use special wall plugs obtainable from most DIY

stores.

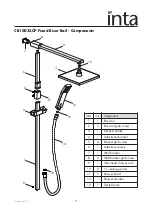

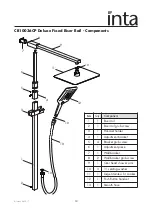

Fixed Riser Rail - Assembly

Attach the shower head (11) to the shower arm using a ½” sealing washer (10) to create a water

tight seal onto the riser rail assembly.

Re-assemble the riser rail to the shower valve and over head arm (9) onto the wall bracket

(7) ensuring the riser rail is vertical.

Tighten the two wall bracket grub screws (8) to secure the riser rail.

Secure the grub screw (2) at the bottom of the riser rail to fix in position.

Connect the shower handset (12) to the flexible hose (13) and the hose to the bottom outlet of the

shower valve, ensure the ½” sealing washers (10) are fitted.

Turn on the water supply and check joints for leakage.

Содержание Nulo CB10032CP

Страница 21: ...Intatec Ltd 2017 20 Notes...

Страница 22: ...Intatec Ltd 2017 21 Notes...

Страница 23: ...Intatec Ltd 2017 22 Notes...