34

9.5. Plan for maintenance jobs

1.

After first two hours of work always:

Check the belt tension

Check if all bolts and taper locks are tightened enough

Do the same also after each belt changing.

2.

After every 8 hours always check:

If the nuts are tightened enough,

A wear and condition of working tools,

Belts and taper locks

,

A condition of safe guards,

Oil level in the gearbox,

That any foreign parts are not stuck on the rotor shaft,

That the frame and the 3-point hitch are in good condition,

That all parts are greased well.

3.

On every 100 hours we recommend to:

Check and grease the PTO shaft

4.

On every 12 months we recommend to:

Change the oil in the gearbox and check the belts tension.

9.6. Replacement of working tools

Immediately after you notice that working tools are damaged, change

them. If it is necessary to change only few blades, always change the

broken or worn one and the one diametrically opposite in order to

maintain the balance. If the rotor shaft is vibrating after changing the

blades, immediately stop the machine. The machine must be balanced

before any work.

Содержание MKM

Страница 33: ...33 Fig 33 Fig 34 Fig 37 Fig 38 1 Fig 34 6 Fig 35 Fig 36 Fig 38 2 5 9 4 10 7 8 3 1 2 ...

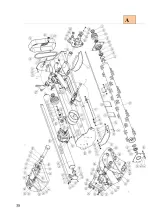

Страница 38: ...38 A ...

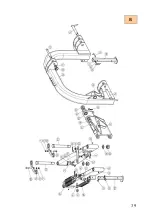

Страница 39: ...39 B ...