32

On every eight hours check that all nuts are tighten

enough.

Never tighten the nuts on the connecting part (Fig.32)

completely, the connecting parts must remain movable.

Proper tighten nuts are when tighten the nuts till the end

and than loose them for ¼ of the round.

At greasing use the glaves. After greasing always wash

your hands.

Use type LIS 3 for greasing.

9.4. Greasing

The machine has the following greasing points:

Left and right bearing on the rotor shaft (Fig.35/7,8)

Left and right bearing on the rear roller (Fig.36/9,10)

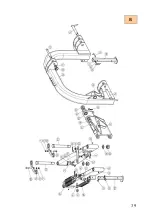

Pins of the arm (Fig.33/1-3, Fig.34/4,5)

Connection (Fig.34/6)

End parts of PTO shaft

Hydraulic cylinder (Fig.37)

Lifting system (Fig.38/1,2)

Before any greasing operation read these instructions

first.

Содержание MKM

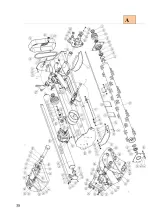

Страница 33: ...33 Fig 33 Fig 34 Fig 37 Fig 38 1 Fig 34 6 Fig 35 Fig 36 Fig 38 2 5 9 4 10 7 8 3 1 2 ...

Страница 38: ...38 A ...

Страница 39: ...39 B ...