PARA

METER

DESCRIPTION

DEFAULT

DISPLAY

PARA

METER

DESCRIPTION

DEFAULT

DISPLAY

ALARM

INHIBIT

This parameter can be used to inhibit (suppress) the Alarm activation upon power-up

conditions by setting the parameter value to ‘YES”. From Power-up, the Alarm

system remains disabled until PV is found with in the limits.

If Alarm activation is desired even under Power-up condition, Set this parameter

value to ‘NO’.

NO

ALARM

LOGIC

DIRECT

If this parameter is set as ‘Direct’, Relay/SSR energizes under Alarm condition &

remains De-energized otherwise. ‘Direct’ setting is generally used for Audio/Visual

Alarm Output.

If this parameter is set as ‘Reverse’, Relay/SSR De-energizes under Alarm condition

& remains energized otherwise. ‘Reverse’ setting is generally used for tripping the

process under Alarm condition.

ALARM

ACK.

AUTO

Once Alarm is activated, it can be de-activated either by pressing UP key or when PV

falls within the alarm limits.

Once Alarm is activated, it remains activated until manually acknowledged by UP

key.

Once Alarm is activated, user has following three options to de-activate it.

When PV falls within the programmed limits, Alarm will be de-activated automatically.

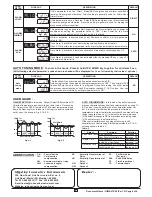

ON-OFF ACTION:

In this mode, Output (Relay/SSR) remains ON

till actual temperature reaches to the set point value. On reaching

SP, Output turns OFF & remains OFF till actual temperature drops

down (in Heat Logic) or raises (in Cool Logic) equal to hysterisis

set by user. (As shown in Fig. 3.1 & 3.2).

USER GUIDE :

(All following selected parameter’s code shown in shaded will be displayed for 1 sec. followed by their values / options)

HEAT LOGIC/ON-OFF

TIME

TEMP ( C)

0

HYSTRISIS

SP

ON

ON

ON

AMB

O/P

OFF

OFF

TIME

COOL LOGIC / ON OFF

O/P

O/P

TEMP ( C)

0

AMB

HYSTERISIS

ON

ON

ON

SP

OFF

OFF

Table: 3

Adjust

Proportional Band

Integral Time

Derivative Time

Slow Response

Over Shoot or Oscillations

Slow Response

Instability or Oscillation

Slow Response or Oscillation

High Over Shoot

Decrease PB

Increase PB

Decrease Int

Increase Int

Decrease Dt

Increase Dt

Symptom

Solution

AUTO TUNING MODE :

In this mode, Controller learns the

process characteristics by itself and calculates the required P, I

& D values. It can be performed at any time after power ON

but, it is best to start it when the process is at Ambient

temperature in order to minimize overshoot & undershoot. Auto

tuning is applied in case : (1) Initial set up for a new process.

(2) Substantial change in SP from previous auto tuning value.

(3) Control accuracy is not satisfactory.

If the control performance by using auto-tuning is still

unsatisfactory, User can apply further adjustments of P, I & D

values as shown in table 3.

ABBREVIATION :

NC

: Normally Close terminal of

Relay

NO

: Normally Open terminal of

Relay

OP1

: Output 1

OP2

: Output 2

C.A.

: Control Action

CJC

: Cold junction

compensation

CM

: Common terminal of relay

LWC

: Lead wire (Length)

compensation

SP

: Set Point Value

(Set temp.)

SSR

: Solid State Relay

T.P.

: Time Proportional

T/C

: Thermocouple

Fig: 3.1

Fig: 3.2

Auto

tuning

mode

This function will be executed only if selected control action is PID.

Auto-tuning function is enabled by setting this parameter to ‘YES’. The decimal of LSB

flashes till Auto tuning function is in progress. During Auto-tuning, Controller learns

the process characteristics by itself & calculates required P, I & D values. User can

cancel or abort this feature by setting this parameter to ‘NO’.

NO

AUTO TUNING MODE :

To enter in this mode, Press & hold UP & DOWN key together for minimum 3 sec.

338, New Sonal Link Service Ind. Est. no.2 ,

Link Road, Malad (W), Mumbai - 400064.

Tel: 022-66939916/17. Fax: 022-66939918

E-mail:[email protected] ;

Website: innovativeinstrument.com

: Innovative Instruments

Mfgd by

: -

Dealer

6

Document Name : OIM AI-7X42 (Ver 1.2) Page 6 of 6