4

1

S

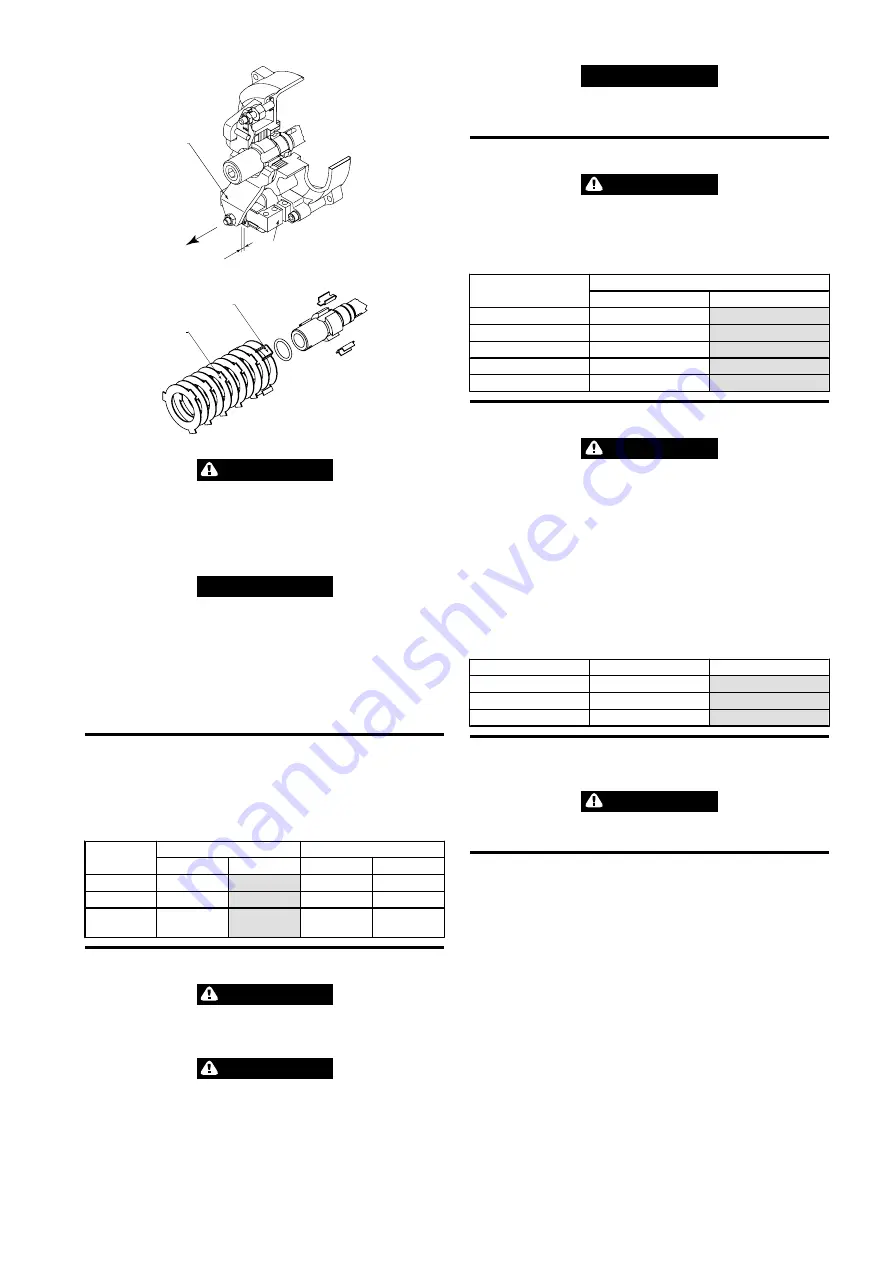

(Dwg. MHP3333)

3

2

(Dwg. MHP3334)

CAUTION

•

Should the brake magnet (1) hum, buzz or vibrate, then the air gap (S) must

be reset in accordance with Table 4 ‘Brake Air Gap (DC Brake)’

•

If the lifting speed is only reached slowly or the load drops a little further

after it has been lowered, this is a sign of oily or sticky brake discs (2) or the

closing of the disc cage (3). Dismantle brake discs, clean and degrease. Disc

cage to be replaced if damaged.

NOTICE

•

By releasing the disc brake [carefully pull on the brake arm (4)] the load can

be lowered in a manual mode.

•

Replace brake discs if they are distorted or severely discolored.

1. Turn nut (5) or (7) until the ‘S’ gap (refer to Table 4 ‘Brake Air Gap (DC Brake)’

2. Push brake solenoid in and rotate cup disc (11) with fingers. Disc should rotate

with a little drag. Loosen nut on capscrew (8). Adjust capscrew until disc rotates

with a little drag. If cup disc is too loose the brake will chatter or hum during

operation.

3. Repeat steps 1 and until ‘S’ gap is correct and disc cup just rotates.

n

Brake Test

1. Use a test load that is 100% of hoist capacity.

2. With cover off, hoist load, in low speed mode, approximately 1 ft. (0.3 m).

3. Listen to brake while hoisting.

4. When hoisting stops, brake should hold load.

Table 4: Brake Air Gap (DC Brake)

Brake type

Brake Air gap ‘S’

Number of discs

(inch)

(mm)

internal

external

QCH50

0.080

2.00

5

5

QCH100

0.080

2.00

7

7

QCH2

00/300/500

0.080

2.00

8

8

n

Load Chain

WARNING

•

Before conducting maintenance on the hoist, lower and remove suspended

load. Disconnect electrical supply and remove hoist from overhead

suspension.

CAUTION

•

The chain is to be replaced when the measurements exceed those defined

in the Table 2 ‘Load Chain’ on page 3. The chain wheel and chain guide are

to be checked for wear at the same time, and, where necessary are to be

replaced.

•

Only original chains are to be used. The chain links are not to be welded.

NOTICE

•

For ease of installation, do not remove the old chain from the hoist. The old

chain can be used to feed the new chain through the hoist by connecting

them with a “C” link.

n

Limit Stop Assembly

CAUTION

•

Defect spring elements and rubber buffers are to be replaced.

Screw connections at the limit stop and shims at lower sheaves are to be checked

and, where necessary, tightened to the right torque. For torque values see Table 5.

Table 5: Torque Values

Dimension

Torque

lbs-in

N-m

M5

53

6

M6

88

10

M8

212

24

M10

425

48

M12

732

83

n

Gears

CAUTION

•

Use extreme care when removing gear end cover to avoid grease spillage.

The gear compartment is filled with grease at the factory to provide continual

lubrication. Replacement of the grease for the life of the hoist should not be required.

n

Lubrication grease:

Strub N142 4

Compatible with Type DIN 51502 : GP OM-2

If it becomes necessary to remove the gear end cover, first ensure the hoist body is

standing on end with the gear end cover up. Failure to observe this procedure will

allow the grease to flow from the hoist. Whenever the gear end cover is removed,

always replace the cover gasket. For quantity refer to Table 6.

Table 6: Gear Case Greasing Quantity

Model

lbs

kg

QCH50

0.88

0.40

QCH100

2.20

1.00

QCH200/300/500

4.00

1.80

n

Slip Clutch

The slip clutch is pre-adjusted. The lining is wear resistant.

CAUTION

•

An adjustment of the slip clutch may only be effected by qualified personnel

and must be entered in the inspection pass.

n

General Overhaul

On reaching the theoretical service life (no later than 10 years for collection without

BDE), a general overhaul is to be performed. Hereby the device is put into a condition

allowing a safe operation within another period of utilization (service life).

For this, components according to Table 7 must be inspected and/or exchanged.

The inspection of as well as the approval for further utilization must be performed

either by an expert company authorized by the manufacturer, or by the

manufacturer personally.

The inspector determines:

- the new possible theoretical utilization

- the max. period until the next general overhaul

Such data is to be documented in the inspection report.

Form 16586737 Edition 4

7

Содержание QCH100

Страница 10: ...www ingersollrandproducts com...