6

MHD56208 - Edition 3

INSTALLATION

Prior to installing the motor, carefully inspect it for possible

shipping damage.

• Owners and users are advised to examine specific, local or

other regulations, including American National Standards

Institute and/or OSHA Regulations which may apply to a

particular type of use of this product before installing or

putting motor to use.

Mounting

• Use motor eyebolt only when lifting motor. Motor eyebolt is

designed to hold only weight of motor.

The

MMP150

air motor may be mounted in any orientation. The

lubrication free design removes any consideration for maintaining

an oil sump or vent cap orientation. However; if using a motor

mounted control valve operator safety and ease of operation

should be considered.

Base Mounted Installation:

1.

Surface must be flat and of sufficient strength to handle the

motor and any components attached or connected to it.

2.

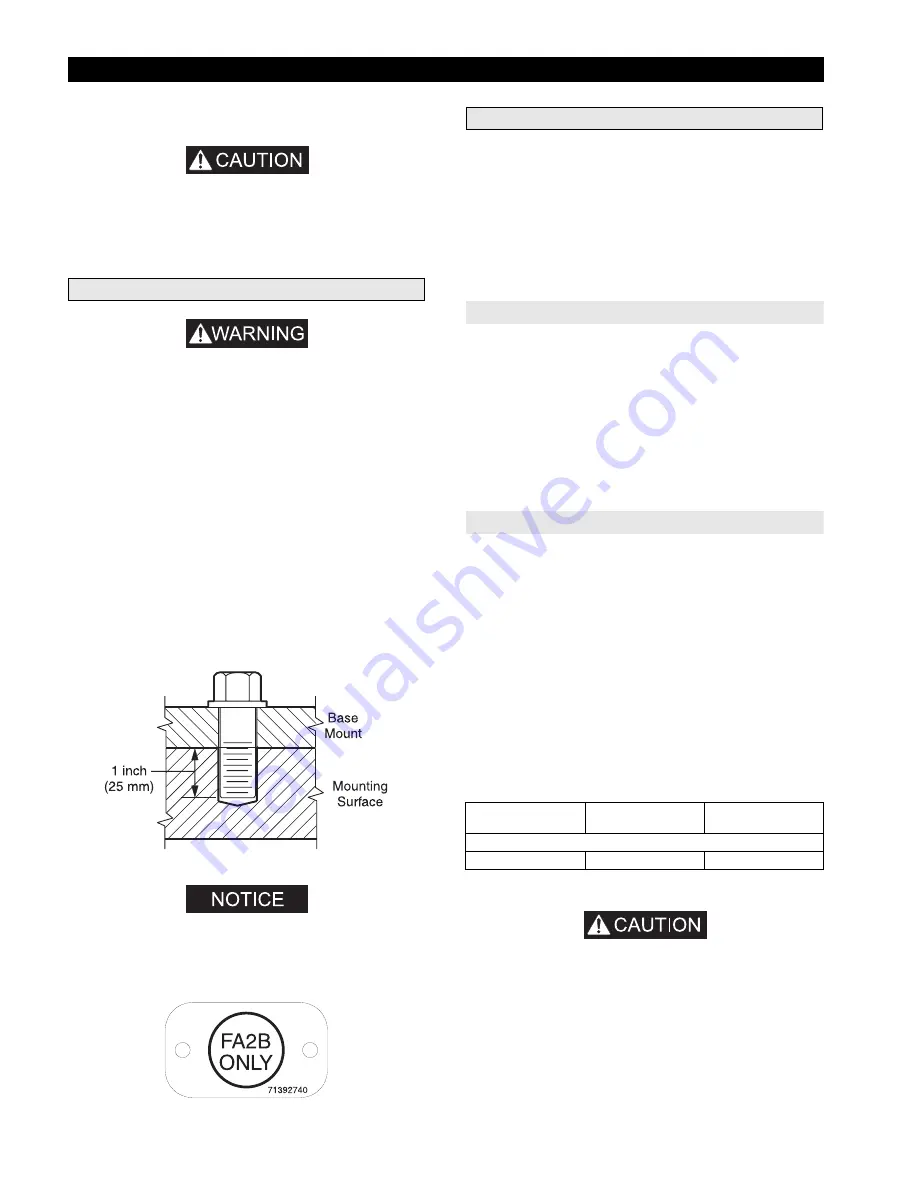

Mounting bolts must be 3/4 inch (18 mm) Grade 8 or better.

If mounting surface is threaded the minimum depth of thread

engagement should be 1 inch (25 mm). Refer to Dwg.

MHP2019 on page 6. For mounting into drilled holes, use

self-locking nuts and lockwashers to secure fasteners.

3.

Refer to Dwg. MHP2004 on page 5 for bolt hole location

dimensions.

(Dwg. MHP2019)

• Control valves supplied with motors will have label 71392740

attached. Label is only applicable if motor is used in an

Ingersoll Rand winch application. Refer to Dwg. MHP2335 on

page 6.

(Dwg. MHP2335)

Air Supply

The air supply should be clean and filtered to ensure optimum

motor performance and minimize wear. Foreign particles are the

primary cause of motor wear and breakdown. Using an air filter

will improve overall motor performance and reduce unscheduled

downtime.

Maximum air consumption is 425 scfm (12 cu. m/min) at rated

operating pressure of 90 psig (6.3 bar/630 kPa) at the motor inlet.

If air supply varies from recommended, motor performance will

change. Refer to ‘Performance Graphs’ on page 4.

Air Lines

The inside diameter of motor air supply lines must be at least

1-1/4 inch (32 mm) to achieve maximum performance. Use of

smaller diameter lines will result in reduced performance (lower

speeds). Before making final connections, all air supply lines

should be purged with clean, moisture-free air or nitrogen before

connecting to motor inlet. Supply lines should be as short and

straight as installation conditions permit. Long transmission lines

and excessive use of fittings, elbows, tees, globe valves etc. cause

a reduction in pressure due to restrictions and surface friction in

the lines.

Air Line Lubricator

Refer to Dwg. MHP0191 on page 7.

An air line lubricator is not required with the

MMP150

air motor

when supplying air source is either a portable compressor or air

compressor system without an air dryer or coalescing filter located

between the compressor and motor. However, using an air line

lubricator will extend piston ring life.

The lubricator must have an inlet and outlet at least as large as the

inlet on the motor directional control valve. Install air line

lubricator as close to air inlet on motor as possible.

Air Spring Operation

Air motors are often used as ‘Air Springs’. This refers to operating

the motor against normal motor rotation. When used for this

purpose an ‘Air Line Lubricator’ is required.

Lubricator Settings

• Shut off air supply before filling air line lubricator, if

equipped.

If equipped, the airline lubricator should be replenished daily with

ISO VG 32 (10W SAE) oil. Refer to “Lubricator Settings” on

page 6.

For optimum performance and maximum parts durability, provide

a lubricated air supply. The air motor should be installed as near as

possible to the compressor or air receiver. Recommended

pressures and volumes are measured at the point of entry to the air

motor directional control valve.

Without

Lubricator

With

Lubricator

Air Spring

Operation

(drops per minute)

0

3-6

6-8

Do not exceed values stated.

Содержание MMP150

Страница 5: ...MHD56208 Edition 3 5 Dwg MHP2004...

Страница 23: ...MHD56208 Edition 3 23 SERVICE NOTES...

Страница 26: ...26 MHD56208 Edition 3 SERVICE NOTES...

Страница 36: ...www irtools com...