Book 43212455 (11/03)

33

SCAVENGE LINE

High pressure air can cause severe injury or

death from hot oil and flying parts. Always

relieve pressure before removing caps, plugs,

covers or other parts from pressurized air

system.

The scavenge line originates at the receiver

separator tank cover and terminates at the

compressor airend through an orifice. Once a

year or every 2000 hours of operation, whichever

comes first, remove this line and the orifice,

thoroughly clean, then reassemble.

Excessive oil carry-over may be caused by an

oil-logged separator element. Do not replace

element without first performing the following

maintenance procedure:

1.

Check the oil level. Maintain as indicated

earlier in this section.

2. Thoroughly clean scavenge line, any

orifice and check valve.

3. Assure minimum pressure valve (if so

equipped) has proper setting.

4.

Run unit at rated operating pressure for

30 to 40 minutes to permit element to

clear itself.

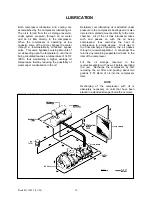

EXTERIOR FINISH CARE

The unit was painted and heat cured at the factory

with a high quality, thermostat polyester powder

coating. The following care will ensure the longest

possible life from this finish.

1. If necessary to remove dust, pollen,

etc. from housing, wash with water and

soap or dish washing liquid detergent.

Do not scrub with a rough cloth, pad,

etc.

2. If grease removal is needed, a fast

evaporating alcohol or chlorinated

solvent can be used.

3. If the paint has faded or chalked, the

use of a commercial grade, non-

abrasive car wax may partially restore

the color and gloss.

Note: This may cause some dulling of the

paint finish.

WARNING

Содержание HP600CMH

Страница 8: ...Book 43212455 11 03 8 IMPORTANT SAFETY INSTRUCTIONS ...

Страница 9: ...Book 43212455 11 03 9 ...

Страница 10: ...Book 43212455 11 03 10 ...

Страница 14: ...Book 43212455 11 03 14 fold ...

Страница 37: ...Book 43212455 11 03 37 ...

Страница 44: ......