Page 8 of 8

S237-SA (en)

PN 97999-1860

install two new Oiler Felts (4) in the Oiler Body,

and retain them with the Oiler Adjusting Screw

(5). Run the Screw in until its trailing face is flush

with the face of the Oiler Body.

24. Install the Oiler Body O-rings (3) and (6) in their

respective grooves on the Oiler Body.

25. Install the Oiler Body Assembly in the Backhead

and retain it with the Oiler Body Retainer (7).

26. Place the Housing Seal (17) on the rim of the

Housing.

27. Place the Backhead (1) on the Housing, making

certain the Cylinder Dowel engages the dowel

hole in the Backhead. Install the Backhead Cap

Screws (13) and Lock Washers (12). Tighten them

to 20 ft-lb (27 Nm) torque.

28. Lay the Pump on its side and slide the Impeller

(41), hub side first, on the splined end of the Ro-

tor Shaft. Manually rotate the Impeller. If it rubs

against the Housing, install an Impeller Shim (40)

or Shims as required to provide running clear-

ance between the Impeller and Housing.

29. Install the Impeller Retaining Washer (42) and

Screw (43). Tighten the Impeller Retaining Screw

to 12 to 15 ft-lb (16.2 to 20.3 Nm) torque.

30. For the most efficient operation of the Pump,

particularly against high heads, it is necessary

that the clearance between the Impeller and Im-

peller Cover (45) be regulated at 0.010”. Place the

Impeller Cover on the base of the Housing, using

the required Impeller Cover Shim (44) or Shims to

obtain the desired clearance.

31. Place the Inlet (46) against the Impeller Cover

and install the Impeller Cover Cap Screws (48)

and Lock Washers (47). Tighten the Cap Screws to

9 to 12 ft-lb (12.2 to 16.2 Nm) torque.

32. Inject 10 or 15 strokes of Ingersoll-Rand No. 80

Water Pump Grease into the Grease Fitting (15)

on the Motor Housing (14). Use the No. P25-228

Grease Gun.

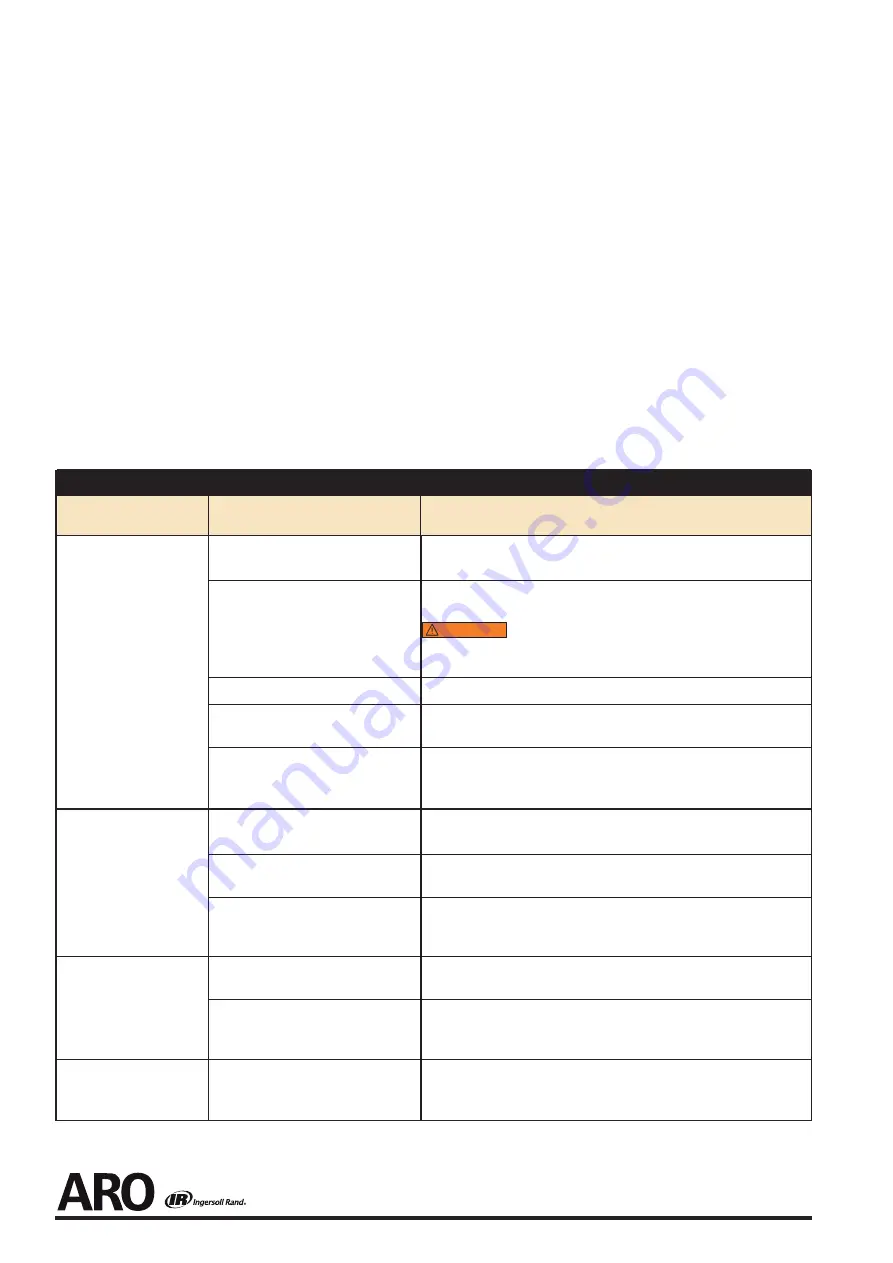

TROUBLESHOOTING GUIDE

Trouble

Probable Cause

Solution

Low power or low free

speed

Low air pressure at the Inlet

Check the air pressure at the Inlet. The pressure must not exceed 90

psig (6.2 bar/620 kPa).

Plugged Inlet Bushing Screen or Air

Strainer Screen

Clean the Screen in a clean, suitable, cleaning solution. If it cannot be

cleaned, replace it.

WARNING

Never operate a Sump Pump without an Inlet Screen.

Ingestion of dirt into the Sump Pump can, in some cases, cause an

unsafe condition.

Worn or broken Vanes

Replace the complete set of Vanes.

Worn or broken Cylinder

Replace the Cylinder if it is worn or broken or if the bore is scored or

wavy.

Improper lubrication or dirt build -up

in the motor.

Lubricate the Sump Pump as instructed in

LUBRICATION.

If lubrica-

tion does not result in satisfactory operation, disassemble the motor

inspect and clean all parts.

Rough operation

Worn or broken Rear Rotor Bearing or

Front Rotor Bearing

Examine each Bearing. Replace the Rear Rotor Bearing Seal Assembly if

worn or damaged or replace the Front Rotor Bearing.

Worn Rotor Key

Replace the Key. Check the Arbor and Rotor for keyslot wear and re-

place if necessary.

Bent Arbor

Mount the Arbor on centers. Check the bearing diameter runout with

an indicator. Replace the Arbor if runout exceeds 0.002” Total Indicator

Reading.

Scoring of End Plates or

Cylinder

Improper assembly

Make certain that all motor parts are properly aligned prior to clamp-

ing the motor assembly.

Rotor Bearing Seal misalignment

Loosen the Cylinder Case Screws. Rotate the spindle by hand to align

the seal. Re-tighten the Screws to 14 ft-lb (19 Nm) torque. The Spindle

must rotate freely.

High free speed

Worn Rotor Bearing Seal

Replace the Rotor Bearing Seal if the outside high diameter of the hub

is worn to 1.76” or smaller and/or the large inside diameter is worn

0.910” or larger.