Page 6 of 12

PP10A-XXX-XXX-A (en)

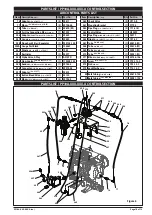

PARTS LIST / PP10A-XXX-XXX-A FLUID SECTION

FLUID SECTION SERVICE KITS (637401-XXX or 637401-XX)

For Fluid Kits With Seats:

637401

-XXX fluid section service kits include: Seats (see SEAT Option, refer to -XXX in chart below), Balls (see

BALL Option, refer to -XXX in chart below), Diaphragms (see DIAPHRAGM Option, refer to -XXX in chart below), and items 19, 70, 144,

175 (listed below) plus items 174 and 94276 Lubriplate

®

FML-2 grease (page 7).

For Fluid Kits Without Seats:

637401

-XX fluid section service kits include: Balls (see BALL Option, refer to -XX in chart below), Dia-

phragms (see DIAPHRAGM Option, refer to -XX in chart below), and items 19, 70, 144, 175 (listed below) plus items 174 and 94276 Lubri-

plate® FML-2 grease (page 7).

MATERIAL CODE

[A]

= Aluminum

[B]

= Nitrile

[C]

= Carbon Steel

[Co] = Copper

[MSp] = Medical Grade

Santoprene

[Sp] = Santoprene

[SS] = Stainless Steel

[T]

= PTFE

COMMON PARTS

Item

Description (size)

Qty Part No.

[Mtl]

1 Connecting Rod

(1) 97146

[C]

5 Back-Up Washer

(2) 95990-3

[A]

9 Washer

(2) 93189-1

[SS]

14 Bolt

(M12 x 1.75-6g x 25mm)

(2) 95997

[SS]

68 Air Cap

(1) 95994-6

[A]

69 Air Cap

(1) 95994-5

[A]

70 Gasket

(2) 95843

[B]

74 Pipe Plug

(1/4 - 18 NPT)

(1) Y17-51-N

[C]

126 Pipe Plug

(1/4 - 18 NPT)

(1) Y17-13-S

[SS]

Item

Description (size)

Qty Part No.

[Mtl]

131 Screw

(M8 x 1.25 - 6g x 95 mm)

(4) 96001

[C]

144 “U” Cup

(3/4” x 1-1/8” OD)

(2) Y186-49

[B]

175 “O” Ring

(5/8” x 13/16” OD)

(2) Y325-114

[B]

180 Washer

(0.406” ID x 0.031” thick)

(4) 96006

[Co]

181 Roll Pin

(Ø 0.156 x 0.500)

(4) Y178-52-S

[SS]

195 Nut

(M8 x 1.25 - 6h)

(4) 96005

[SS]

208 Label

(1) 93007

250 Screw, Self-Tapping

(1/4” - 14 x 1/2”)

(1) Y334-104-C [C]

SEAT OPTIONS

PP10A-XXX-XXX-A

BALL OPTIONS

PP10A-XXX-XXX-A

“21”

“22”

(2-1/2” diameter)

-XXX Seat

Qty [Mtl]

-XXX Ball

Qty [Mtl]

-AXX 96152-A (4) [Sp]

-XAX 93278-A (4) [Sp]

-SXX 96151

(4) [SS]

DIAPHRAGM OPTIONS PP10A-XXX-XXX-A

Service Kits

with Seats

Service Kit

without Seats

“7”

“19”

“33”

-XXX

-XXX = (Seat)

-XXX = (Ball)

-XXX = (Diaphragm)

-XX = (Ball)

-XX = (Diaphragm) Diaphragm Qty [Mtl]

“O”

Ring Qty [Mtl]

“O”

Ring Qty [Mtl]

-XXA 637401-XXA

637401-XA

96267-A

(2) [Sp] 93280 (4) [E] 93279 (4) [E]

-XXM 637401-XXM

637401-XM

96267-M

(2) [MSp] 93282 (4) [T] 93281 (4) [T]

MANIFOLD CONNECTION / FLUID CAP MATERIAL OPTIONS PP10A-XXX-XXX-A

Aluminum

Stainless Steel

NPT

BSP

NPT

BSP

PP10A-AAX-XXX

PP10A-BAX-XXX

PP10A-ASX-XXX

PP10A-BSX-XXX

Item Description

(size)

Qty Part No.

[Mtl] Part No.

[Mtl] Part No.

[Mtl]

Part No.

[Mtl]

6 Back-Up Washer

(2) 95990-3

[A]

95990-3

[A]

95990-1

[SS]

95990-1

[SS]

15 Fluid Cap

(2) 97684

[A]

97684

[A]

97677

[SS]

97677

[SS]

60 Inlet Manifold

(1) 97686-1

[A]

97686-2

[A]

97679-1

[SS]

97679-2

[SS]

61 Outlet Manifold

(1) 97687-1

[A]

97687-2

[A]

97681-1

[SS]

97681-2

[SS]

63 Pipe Plug

(1 - 11-1/2 NPT)

(2) Y17-125

[A]

- - - - -

- - -

Y17-55-S

[SS]

- - - - -

- - -

(R1, 1 - 11 BSP)

(2) - - - - -

- - -

96160-2

[A]

- - - - -

- - -

96160-1

[SS]

255 Pipe Plug

( 1/4"-18 NPT)

(2) Y17-51-S

[A]

Y17-51-S

[A]

Y17-51-S

[SS]

Y17-51-S

[SS]

EXTERNAL HARDWARE OPTIONS PP10A-XXX-XXX-A

Plated Steel

Stainless Steel

PP10A-XXP-XXX-A PP10A-XXS-XXX-A

Item Description

(size)

Qty Part No. [Mtl] Part No.

[Mtl]

26 Screw

(M8 x 1.25 - 6g x 30 mm)

(8) 95880-1

[C] 95880

[SS]

27 Screw

(M8 x 1.25 - 6g x 40 mm)

(20) 95896-1

[C] 95896

[SS]

29 Nut

(M8 x 1.25 - 6h)

(20) 95879-1

[C] 95879

[SS]

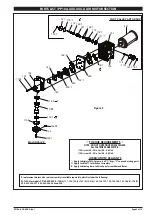

FLUID SECTION DISASSEMBLY

1. Remove (61) outlet manifold and (60) inlet manifold.

2. Remove (22) balls, (19) “O” rings (if applicable) and (21)

seats.

3. Remove (15) fluid caps.

4. Remove the (6) diaphragm washer, (7) diaphragm and (5)

back-up washer.

NOTE:

Do not scratch or mar the surface of (1) diaphragm

rod.

FLUID SECTION ASSEMBLY

y

Assemble in reverse order of disassembly. Refer to the

torque requirements on page 7.

y

Clean and inspect all parts. Replace worn or damaged

parts with new parts as required.

y

Lubricate

®

(1) diaphragm rod and (144) “U” cups with Lu-

briplate FML-2 grease (94276 grease packet is included in

service kit).

y

Examine torque settings after pump has been re-started

and run a while.

Air Motor Kit parts, see pages 8 and 9.