Page 4 of 12

PP10A-XXX-XXX-A (en)

Restart can compress some powders to a solid that may

cause the pump to fail. The pump should cycle until most of

the powder has been purged before it is shut down.

CALIBRATION PROCEDURE ON INITIAL START-UP:

NOTE:

Once these parameters are established for your spe-

cific application, they should not need to be changed.

1. Turn the flow and pressure on the (248) filter / regulator

all the way up.

2. Slowly decrease pressure and flow until pump begins to

labor (work harder).

3. Increase pressure and flow back to a point where the

pump begins to run smoothly. This will optimize the air-

to-powder mix and will help to establish the most effi-

cient working parameters.

If the pump begins to cycle slowly (bog down), the powder

can be purged by depressing the restart button. This will

stop the pump and restart the aeration cycle and allow time

to increase air flow to the aeration ports for proper material

movement.

IMPORTANT

SHUT DOWN PROCEDURE - TO HELP PREVENT PACK-OUT

It is good operating practice to dry cycle the pump 5 - 10

seconds at the end of each dispense cycle. This can be ac-

complished by closing off the powder source at the suction

of the pump or pull wand from material. This will help clear

the pump chambers of any residual powder.

CAUTION

Failure to ensure proper fluidization can

result in internal parts breakage and pump failure.

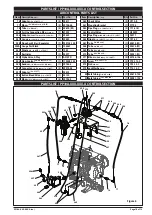

MAINTENANCE

Refer to the part views and descriptions as provided on page

6 through 11 for parts identification and Service Kit informa-

tion.

y

Keep good records of service activity and include pump

in preventive maintenance program.

y

Certain ARO “Smart Parts” are indicated which should be

available for fast repair and reduction of down time.

y

Service kits are divided to service two separate dia-

phragm pump functions: 1. AIR SECTION, 2. FLUID SEC-

TION. The FLUID SECTION is divided further to match

typical part MATERIAL OPTIONS.

y

Provide a clean work surface to protect sensitive internal

moving parts from contamination from dirt and foreign

matter during service disassembly and reassembly.

y

Before disassembling, empty captured material in the

outlet manifold by turning the pump upside down to

drain material from the pump.

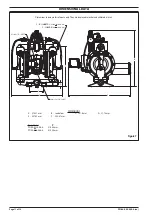

SCHEMATIC CIRCUIT

Figure 2

A212PD

12

14

4 2

Left

2

95077

Air / Nitrogen

Right 4

4

1

2

Exh 24130

1

2

H254PS

94977

3

CP10-B

CP10-B

119309-103

TROUBLESHOOTING

Product discharged from exhaust outlet.

y

Check for diaphragm rupture.

y

Check tightness of (14) diaphragm screw.

Motor blows air or stalls.

y

Check (176) check valve for damage or wear.

y

Check for restrictions in valve / exhaust.

Low output volume, erratic flow, or no flow.

y

Check air supply.

y

Check for plugged outlet hose.

y

Check for kinked (restrictive) outlet material hose.

y

Check for kinked (restrictive) or collapsed inlet material

hose.

y

Suction hose must be a non-collapsing type, conductive

and capable of pulling a high vacuum (up to 30” mer-

cury).

y

Check all joints on the inlet manifolds and suction con-

nections. Connection must be air tight.

y

Inspect the pump for solid objects lodged in the dia-

phragm chamber or the seat area.

y

Loctite® and 242® are registered trademarks of Henkel Loctite Corporation

y

ARO® is a registered trademark of Ingersoll-Rand Company

y

y

Santoprene® is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P.

y

271™ is a trademark of Henkel Loctite Corporation

y

y

Lubriplate® is a registered trademark of Lubriplate Division (Fiske Brothers Refining Company)

y