SECTION 7: ILLUSTRATED PARTS LIST

99906549 rev 00 (JANUARY-2020)

7 - 21

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

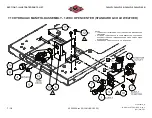

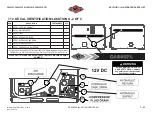

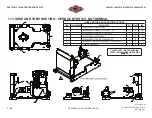

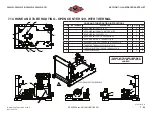

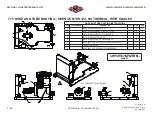

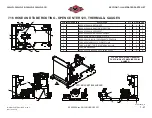

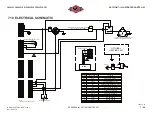

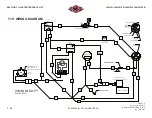

7.11 HYDRAULIC MANIFOLD ASSEMBLY - CLOSED CENTER 24V (STANDARD & COLD WEATHER)

ITEM

DESCRIPTION

VANAIR PART

NUMBER

IMT PART

NUMBER

QTY

1

CONNECTOR, #4 MSAE x #4 MJIC

260387-103

1

2

CONNECTOR, #16 MSAE x #8 MJIC

260387-118

1

3

CONNECTOR, #16 MSAE x #12 MJIC

260387-119

1

4

BULKHEAD, 1 1/16 - 12UNF x 1 5/16 - UNF

269751

1

5

VALVE, HYD ASSY CLOSE CENTER 24V

277854

1

6

CAP, FEMALE JIC SHIPPING #4 7/16-20

279109-001

1

7

CAP, FEMALE JIC SHIPPING #6 9/16-18

279109-002

1

8

CAP, FEMALE JIC SHIPPING #12 1 1/16-12

279109-005

1

9

CAP, FEMALE JIC SHIPPING #16 1 5/16-12

279109-006

1

10

BRACKET, HYD OIL CLSD CTR MNFLD

279469

1

11

NUT, HEX LOCKING 5/16-18

825505-166

2

12

CAPSCREW, HEX GR5 5/16-18 x 2.75

829105-275

2

13

SCREW, SER WASH 5/16-18 x 1

829705-100

2

14

WASHER, LOCK INTERNAL TOOTH 7/16 INCH

837407-040

1

15

WASHER, LOCK INTERNAL TOOTH 9/16 INCH

837409-045

1

16

WASHER, INTERNAL TOOTH 1 INCH

837414-100

1

17

BULKHEAD, MJIC x MJIC #4

862104-025

1

18

BULKHEAD, MJIC x MJIC #6

862106-038

1

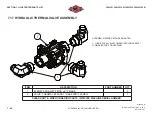

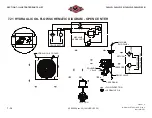

A

Flow Regulator: For

fl

ow regulator replacement, consult the IMT Service Department.

B

Solenoid: For solenoid replacement, consult the IMT Service Department.

PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER.

Содержание CAS40PL

Страница 2: ...BLANK PAGE...

Страница 81: ...BLANK PAGE...