99906549 rev 00 (JANUARY-2020)

5 - 11

SECTION 5: MAINTENANCE

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

2. Position hub on mating shaft. Ideal hub po-

sition is with the pocket face of the hub

fl

ush

with the end of mating shaft. Overhung hubs

should have a minimum shaft engagement

equal to the hub bore diameter.

3. With hub properly positioned, torque clamp-

ing fastener to recommended seating torque.

The manufacturer recommends using me-

dium strength removable Loctite for bore &

key way setscrew (see

Figure 5-6

for proper

bore & key way setscrew seating torques).

4. Repeat steps #2 and #3 for the driven shaft

hub.

5. Move driven and driving equipment togeth-

er until proper distance between hubs is

achieved (assembly gap can be used as

reference when unable to measure distance

between hubs. See

Figure 5-6

for proper dis-

tance between hubs and assembly gap).

6. Ensure driven unit is aligned to driving unit,

within couplings allowable misalignment.

ANGULAR ALIGNMENT

Measure the assembly gap between hubs in

(4) locations 90° apart the measurement range

should not exceed the angular limit listed in

Fig-

ure 5-6

.

PARALLEL ALIGNMENT

Place a straight edge square on the outer diam-

eter of both hubs in (4) locations 90° apart; the

maximum gap should not exceed the o

ff

set limit

listed in

Figure 5-6

.

5.4.7.3 HUB ALIGNMENT CHECK

To ensure alignment, refer to

Figure 5-6

and the

following procedure:

1. Place a straight edge square on the outer di-

ameter of both halves in locations 90° apart.

The maximum gap should not exceed the o

ff

-

set limit as given in

Figure 5-6

.

2. Once this gap is satisfactory, torque screws

to 14 ft-lbs (19.0 Nm).

5.4.7.4 COUPLING MAINTENANCE

Perform the checks and tasks listed below to

keep the CAS40PL coupling in proper working

order.

A

B

KEY

DESCRIPTION

A

DISTANCE BETWEEN HUBS: 0.945 inches

B

ASSEMBLY GAP: 0.118 inches

OFFSET LIMIT: 0.009 inches

ANGULAR LIMIT: 0.030 inches

Figure 5-6: Hub Alignment Check

• Keep coupling components free of dust and

dirt.

• Make sure that the coupling is not in contact

with any non-rotating surfaces.

• Verify application data and review torque spec-

i

fi

cations, mis-alignment and service factors.

If further assistance is needed please contact

the IMT

®

Service Department.

IMPORTANT

Hubs that are modi

fi

ed or machined by the

customer are not covered under the standard

warranty terms. Any modi

fi

cations to instruc-

tions and/or coupling characteristics may result

in a premature failure.

If modi

fi

cations are made by the customer, it

is recommended that the customer adheres to

IMT’s machining standards to ensure proper

operation.

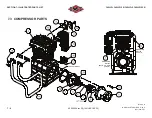

5.4.8 CHECKING HOSES AND WIRING

To maximize the accessible work space needed

for compressor unit maintenance, both side pan-

els (drive assembly access panel and instrumen-

tation panel) must be removed. Consult

Section

Содержание CAS40PL

Страница 2: ...BLANK PAGE...

Страница 81: ...BLANK PAGE...