30

IMT CAS2545 Air Compressor Manual Part No. 99904145

Description of Components

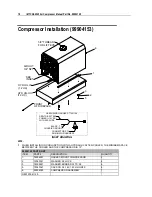

COMPRESSOR ASSEMBLY

The IMT compressor assembly is a positive displacement, oil flooded, rotary screw type unit

employing one stage of compression to achieve the desired pressure. Components include a

housing (stator), two screws (rotors), bearings, and bearing supports. Power from the hydraulic

motor is transferred to the male rotor through a belt and pulley configuration. The female rotor is

driven by the male rotor. There are four lobes on the male rotor and five roots on the female

rotor.

PRINCIPLES OF OPERATION

In operation, two helical grooved rotors mesh to compress air. Inlet air is trapped as the male

lobes roll down the female grooves, pushing trapped air along, compressing it until it reaches the

discharge port in the end of the stator and delivers smooth-flowing, pulse-free air to the receiver.

During the compression cycle, oil is injected into the compressor. The oil lubricates the rotating

parts and bearings; serves as a cooling agent for the compressed air; and seals the running

clearances.

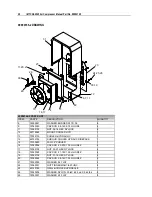

LUBRICATION SYSTEM

Oil from the compressor oil sump, at compressor discharge pressure, is directed through the oil

filter, cooling system, and to the side of the compressor stator, where it is injected into the

compressor. At the same time oil is directed internally to the bearings and shaft seal of the

compressor. The oil-laden air is then discharged back into the sump.

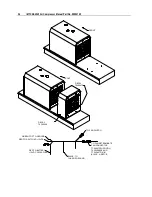

OIL SUMP

Compressed, oil-laden air enters the sump from the compressor. As the oil-laden air enters the

sump, most of the oil is separated from the air as it passes through a series of baffles and

diffusion plates. The oil accumulates at the bottom of the sump for recirculation. However,

some small droplets of oil remain suspended in the air and are passed on to the coalescer.

PRESSURE RELIEF VALVE

The pressure relief valve is set at 210 psi

.

It is located at the top of the air/oil sump. This valve

acts as a backup to protect the system from excessive pressure that might result from a

malfunction.

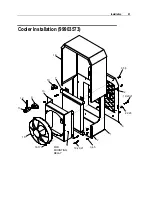

AIR/OIL COALESCER

The coalescer is self-contained within the air end assembly. When air is demanded at the

service line, it passes through the coalescer which efficiently provides the final stage of oil

separation.

Содержание CAS2545

Страница 2: ......

Страница 6: ......

Страница 11: ...Section 1 Compressor Introduction 9 Warning Caution Decals WARNING Do not operate with cover removed...

Страница 15: ...Section 1 Compressor Introduction 13 CAS2545 Performance Charts...

Страница 16: ...14 IMT CAS2545 Air Compressor Manual Part No 99904145...

Страница 17: ...Section 1 Compressor Introduction 15...

Страница 38: ......

Страница 54: ......

Страница 71: ...Parts 69 Electrical Schematic 77441156...

Страница 72: ...70 IMT CAS2545 Air Compressor Manual Part No 99904145 Hydraulic Schematic 99904155...