H H W"

T D

F T T

A

N

[i \X/

R

T

B

B U

N

By following these instructions, in conjunction with the. diagrams

on

the

opposne

page,

the

fitting

ofa

new

ribbon

is

:1

simple

operation.

Before

commencing

the

operation

observe

closely

how

the.

old

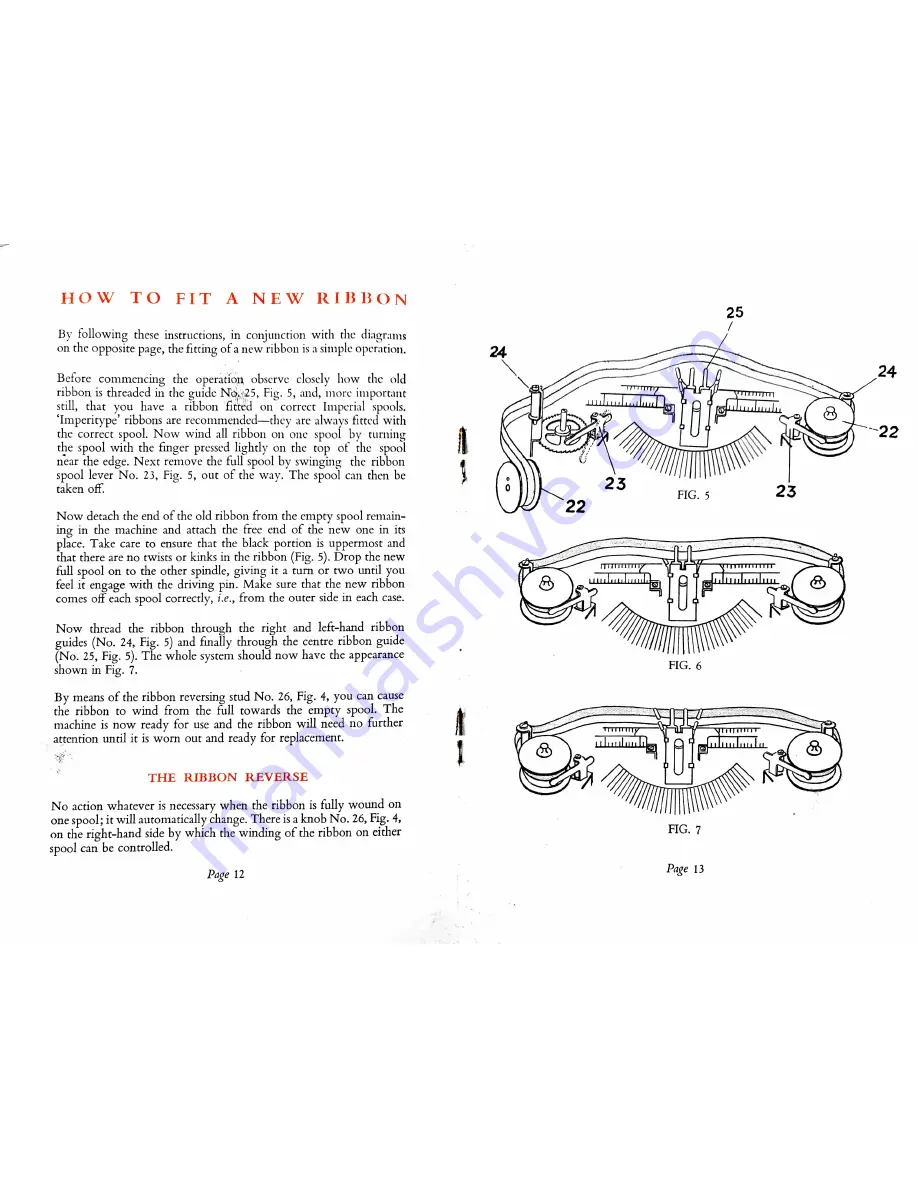

ribbon is threaded in the guide Nq,y;.25, Fig. 5, and, more important

still,

that

you

have

a

ribbon

fitted

on

correct

Imperial

spools.

‘Imperitype’ ribbons are tecommended—they are always fitted with

the correct spool.

Now Wind all ribbon

on one

spool

by

turning

the spool with the finger pressed lightly on the top of. the spool

near

the

edge.

Next

remove

the

full

spool

by

swinging

the

ribbon

spool lever No. 23, Fig. 5, out of the way. The spool can then be

taken of.

N ow detach the end of the old ribbon from the empty spool remain-

ing in the machine and attach the free end of the new one in its

place. Take care to ensure that the black portion is uppermost and

that there are no twists or kinks in the ribbon (Fig. 5). Drop the new

full spool on to the other spindle, giving it a turn or two until you

feel it engage with the driving pin. Make sure that the new ribbon

comes

01?

each

spool

correctly,

i.e.,

from

the

outer

side

in

each

case.

Now

thread

the

ribbon

through

the

right

and

left—hand

ribbon

guides (No. 24, Fig. 5) and finally through the centre ribbon guide

(No. 25, Fig. 5). The whole system should now have the appearance

shown in Fig. 7.

By means of the ribbon reversing stud No. 26, Fig. 4, you can cause

the

ribbon

to

wind

from

the

full

towards

the

empty

spool.

The

machine is now ready for use and the ribbon Will need no further

attention until it is Worn out and ready for replacement.

THE

R US BUN

REVERSE

No action whatever is necessary when the ribbon is fully wound on

one

spool;

it

Will

automatically

change.

There

is

a knob

N o.

26,

Fig.

4,

on

the

right—hand

side

by

Which

the

winding

of

the

ribbon

on

either

spool can be controlled.

Page 12

11

FIG.

6

FIG.

7

Page 13