6

D4 0617GB

December 2000

GREASE

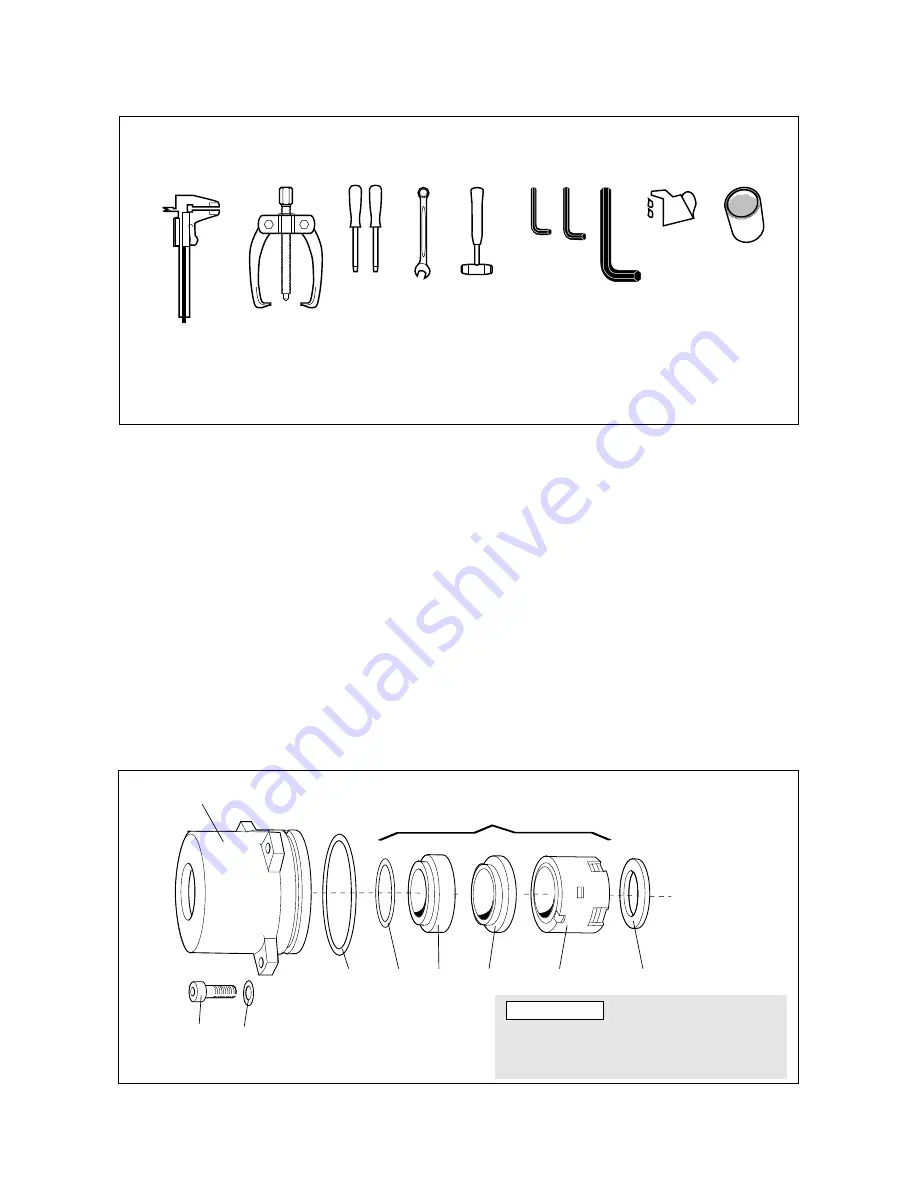

List of tools necessary for dismantling/reassembly

Fig. 3

Sliding Puller

calliper

Plastic

mallet

ACG7 © IMO AB

O-rings

All O-rings found to be hard or damaged shall be

replaced.

Inspection of shaft seal

As the seal faces of a mechanical shaft seal are

lubricated by the fluid, a certain leakage will

always be present. Up to ten drops per hour can be

considered as acceptable. An external visual

inspection of the pump is advisable at least every

two days to assure that the shaftseal is not leaking

too much. Excessively leaking shaft seals should be

changed without delay, as the leakage normally will

grow worse and cause additional damage.

Follow the instructions in the dismantling/reassembly

session.

When working with a shaft seal, cleanliness is of

utmost importance. Avoid touching the seal faces. If

necessary, the seal faces should be cleaned immedi-

ately prior to assembly, using a dust free cloth and

clean solvent.

Never use grease on the seal faces.

D4 5 © IMO AB

Shaft seal – assembly drawing

520A S2 S1 S4

S5

507

521

521A

520

ATTENTION

Be careful to mount these parts in right

order and in right direction!

Look carefully at this drawing!

S1 Seat

S2 O-ring

S4 Seal ring

S5 Bellows unit

2 pcs of

screw-

driver

Screw

spanner

14 mm

Allen keys

5 mm, 6 mm, 10 mm

Oil can

Grease

Shaft seal

D4 4 © IMO AB

Fig. 4