1-26

1-25

19

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

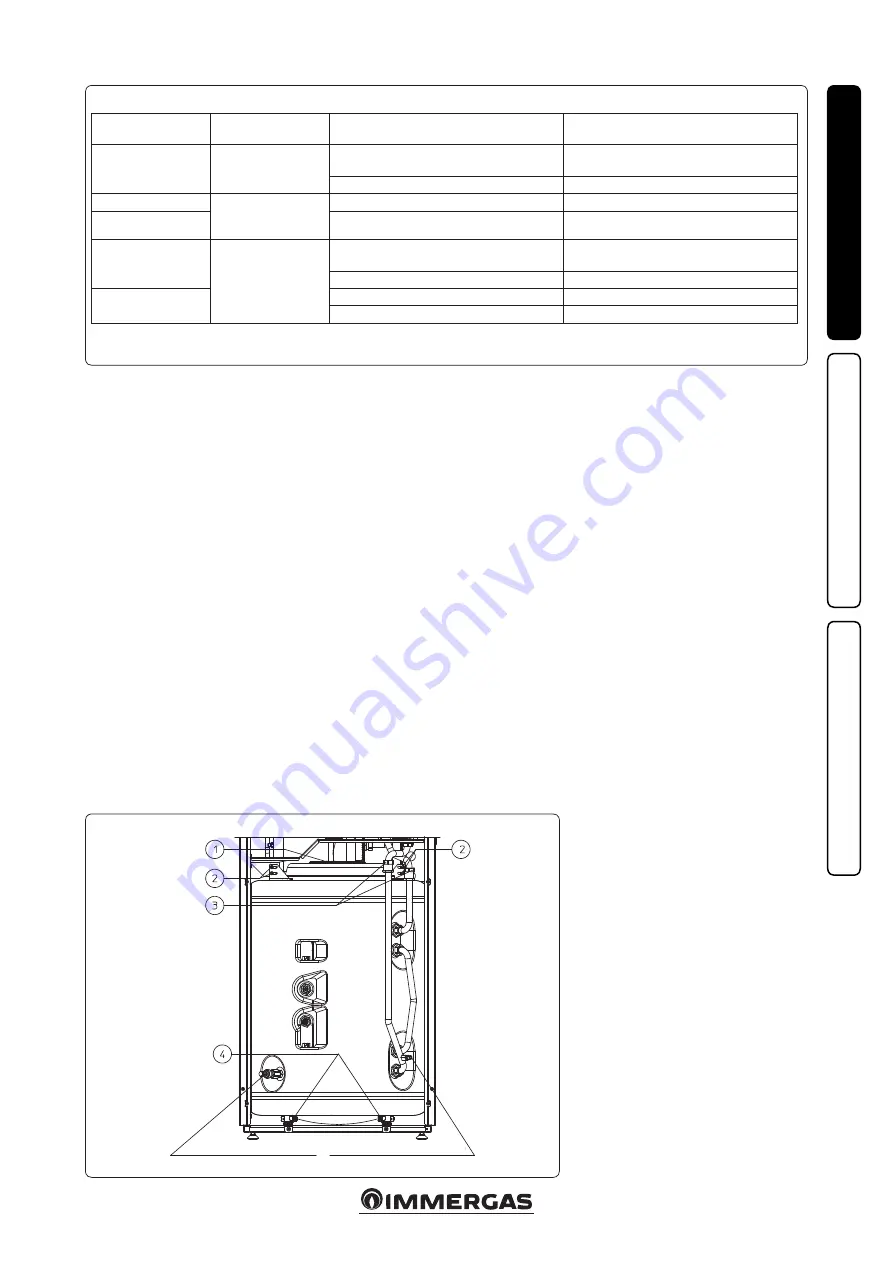

Storage tank unit disassembly.

To disassemble

the storage tank unit, empty the boiler system

by acting on the relevant drain fitting. Before

carrying out this operation, ensure the filling

valve is closed. Close the cold water inlet valve

and open any domestic hot water cock. Loosen

the nuts on the system flow and return pipes (3)

and the cold inlet and hot outlet nuts present

on the storage tank unit (1). Loosen the bracket

fixing screws (2) Remove the screws (4) with the

relative retainer brackets and slide the cylinder

outwards on the relevant guides. Work in reverse

order to assemble the storage tank unit.

N.B.:

have the efficiency of the storage tank Mag-

nesium Anode checked annually by a qualified

firm. The storage tank unit is prepared for intro-

duction of the domestic hot water pump fitting.

1.25 KITS AVAILABLE ON REQUEST.

• Recirculation kit (on request). The boiler

storage tank unit is prepared for application

of the pump kit. Immergas supplies a series of

fittings and attachments that allow connection

between the storage tank unit and domestic hot

water system. The pump probe fitting is already

inserted on the storage unit kit and the indica-

tion of the pump kit attachment is envisioned

on the installation template.

• System cut-off valves kit (on request). The

boiler is designed for installation of system

interception cocks to be placed on flow and

return pipes of the connection assembly. This

kit is particularly useful for maintenance as

it allows the boiler to be drained separately

without having to empty the entire system.

• Polyphosphate dispenser kit (on request). The

polyphosphate dispenser reduces the forma-

tion of lime-scale and preserves the original

heat exchange and domestic hot water pro-

duction conditions. The boiler is prepared for

application of the polyphosphate dispenser kit.

• Zone pumps kit (on request). If the central

heating system is to be divided into several

zones (

max. three

) in order to interlock them

with separate adjustments and to keep water

flow rate high for each zone, Immergas supplies

zone pump kits on request.

• Low temperature kit (on request). If the central

heating system is to be divided into high tem-

perature zones (radiators) and low temperature

zones (floor plants) in order to interlock them

with separate adjustments and to keep water

flow rate high for each zone, Immergas supplies

the low temperature kit on request.

• Solar panels kit (on demand). If solar panels

are to be used for the production of domestic

hot water, Immergas supplies the solar panels

kit on demand.

• Low temperature safety thermostat kit. With

the boiler functioning in direct low tempera-

ture (no control downstream from the boiler),

to prevent problems to the low temperature

system a safety thermostat must be inserted

onto the flow pipe.

The above-mentioned kits are supplied complete

with instructions for assembly and use.

1.24 DOMESTIC HOT WATER STORAGE

TANK UNIT.

The “Hercules Condensing ErP” boiler is the

accumulation type with a capacity of 120 litres.

It contains large coiled stainless steel heat ex-

changer pipes, which allow to notably reduce

hot water production times. These storage tank

units constructed with stainless steel casing and

bottoms, guarantee long duration through time.

The assembly concepts and welding (T.I.G.) are

implemented to the minimum detail to ensure

maximum reliability.

The upper inspection flange ensures practical

control of the storage tank unit and the coiled

heat exchanger and easy internal cleaning.

The domestic hot water connections are placed

on the flange cover (cold inlet and hot outlet)

along with the Magnesium Anode support cap

including the same, supplied as standard for

internal protection of the storage tank unit from

possible corrosion.

Circulating pump

LED

Description

Diagnostics

Remedy

LED steady on

Pump

noisy

Insufficient system pressure, circulating pump

in cavitation

Restore correct thermal circuit pressure

Presence of foreign matter in the impeller

Remove the motor and clean the impeller

Flashing white LED

Noises during cir-

culation of the heat

transfer fluid

Presence of air in the system

Vent the system

LED steady on

Flow rate too high

Reduce rotation speed

LED off

The circulator does

not work

Power outage

Ensure the boiler is correctly powered, ensure

the circulator is correctly powered

Faulty circulating pump

Replace the circulating pump

Red LED

Rotor seized

Remove the motor and clean the impeller

Insufficient power supply voltage

Check boiler power supply voltage

System draining valve

Storage tank draining valve