15

STEMkW Special ed 01/08

EOLO Mini kW Special

Technical Documentation

Technical Documentation

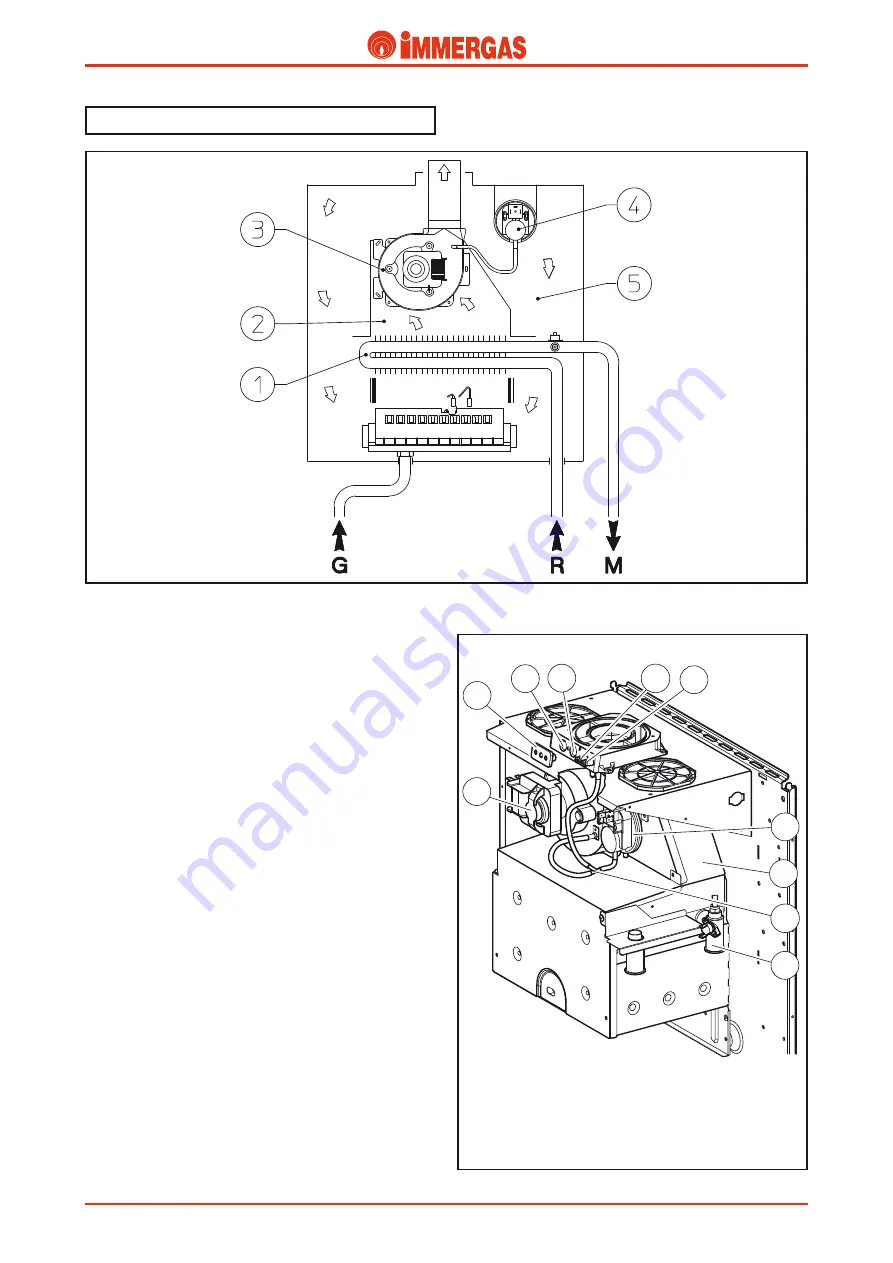

Flue circuit.

Operation.

The products of combustion, after hitting the water-gas exchan-

ger (1), are conveyed to a hood (2) on top of which the fumes

extractor (3) is fitted (fan).

Fan operation guarantees the forced expulsion of the fumes

and, at the same time, creates a vacuum in the sealed chamber

(5) so the combustion air can be aspirated from outside.

Correct fume extraction is controlled by a differential flue

pressure switch (4); when it triggers it either enables or prevents

burner ignition.

Air/fumes testing holes (7-8).

There are two holes at the top on the outside of the sealed

chamber which can be accessed from the front; they are used

to sample combustion air (7) and fumes (8).

The two holes are closed by the one plastic cap (6).

Flue pressure switch signal pressure points (9-

10).

There are two pressure points with screw closing at the top on

the outside of the sealed chamber. They measure the signal at

the ends of the flue pressure switch (4).

The negative pressure point (9) is connected to a Y-shaped

pipe (11) which, in turn, is connected to the negative pressure

point of the flue pressure switch (4)

and to the pressure point

on the fan.

The positive pressure point (10) is connected directly to the

inside of the sealed chamber.

2

1

4

3

7 8

9

11

10

6