25

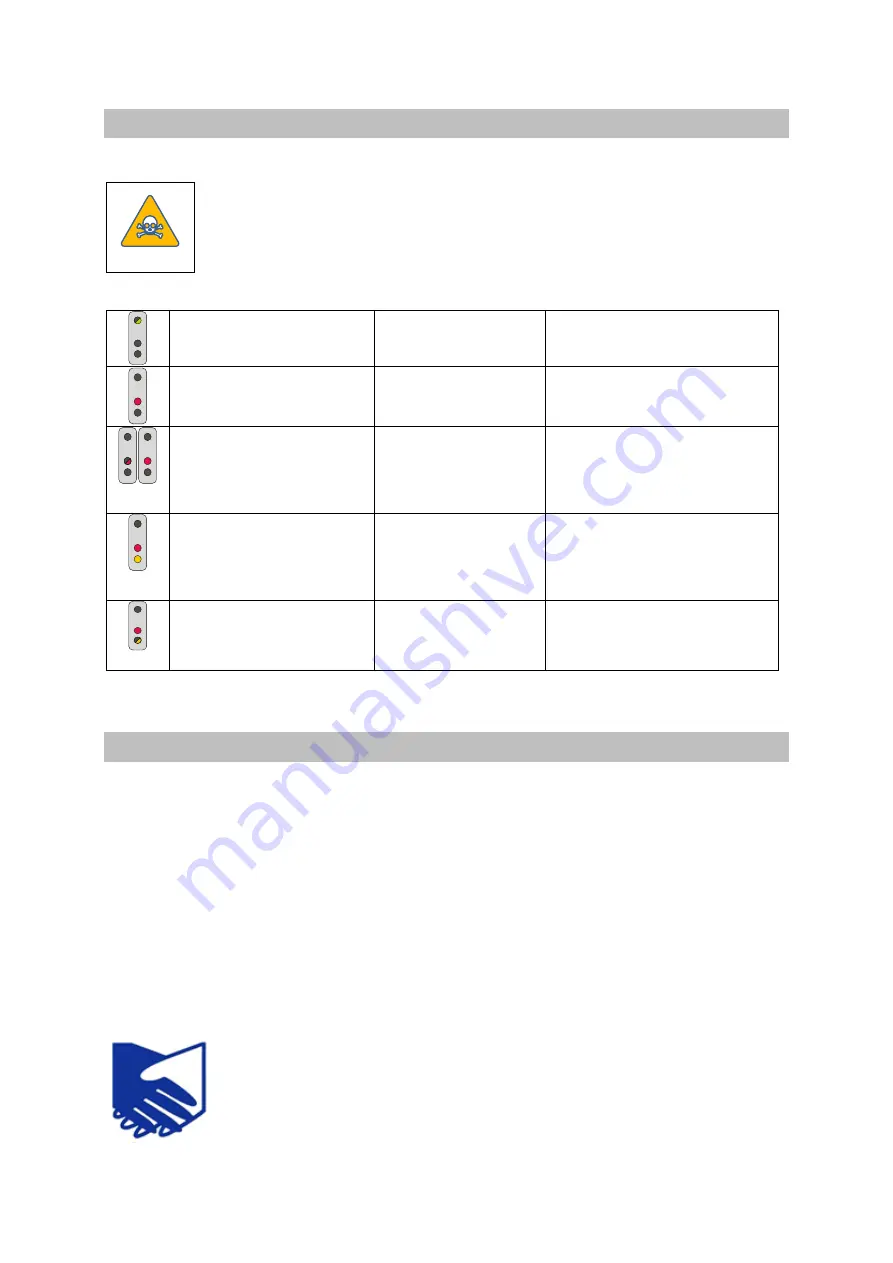

8. Fault analysis and rectification

The device terminal strip is live during operation!!

Before working on the device disconnect it from the mains!!

flashing green LED

(1Hz):

low voltage

Uv < 180V

check power supply

permanent red LED

low water (LLW)

check feed water

flashing red LED for

4..16s

(1 Hz / DIP-switch)

followed by permanent

red LED

insulation electrode

stained

clean probe electrodes

permanent red and

yellow LEDs

system failure

restart controller by

disconnecting from and

reconnecting to power

supply;

change controller

permanent red LED

together with flashing

(1Hz) yellow LED

fault in measuring

cable

(short circuit or cable

break)

check measuring cable

Check cap 4.2, too

9. Warranty

In addition to the statutory warranty, we give a 24-month warranty on our products. The

prerequisite is proper handling in accordance with the installation and operating instructions.

In the case of wearing and replacement parts, the warranty is limited to material and

construction faults. Level probes are wearing parts and are not subject to warranty.

Gefahr

This high-quality IGEMA product was designed, manufactured and tested with the

application of the QM System guidelines in accordance with DIN EN ISO

9001:2015.

If the device supplied indicates transport damage or gives cause for complaint in

spite of our final quality control please contact our SERVICE department on

telephone

+49 2501 92424-0

.by return.

Содержание SMLC2

Страница 26: ...26 10 Conformity declaration...

Страница 27: ...27 11 Certificates PED Type Examination...

Страница 28: ...28 SIL 3 Zertifizierung...

Страница 30: ...30...

Страница 31: ...31...