Changing sensor parameters using the programming menu.

For information on the parameters to be set see the operating

instructions of the respective sensor.

.

Every

modification

of a parameter is

stored in the sensor directly

after confirmation (step 3) and

is effective immediately

. If all

requested parameters are set, programming is finished.

The

menu Snd must not be activated

. Parameters transferred to the

sensor via

Snd would overwrite

the parameter values set with the

programming menu.

The parameter values set with the programming menu are in the sen-

sor and the working memory of the PP2000. They can therefore be

stored permanently

with the menu

Sto

(

→

page 19).

If you change the parameters during operation, the functioning of the

plant will be affected. Ensure that plant malfunction is prevented.

page 24

Remote parameter

setting

Do not activate the

menu "Snd"

Storing possible with

Sto

Remote display, remote evaluation, remote parameter setting

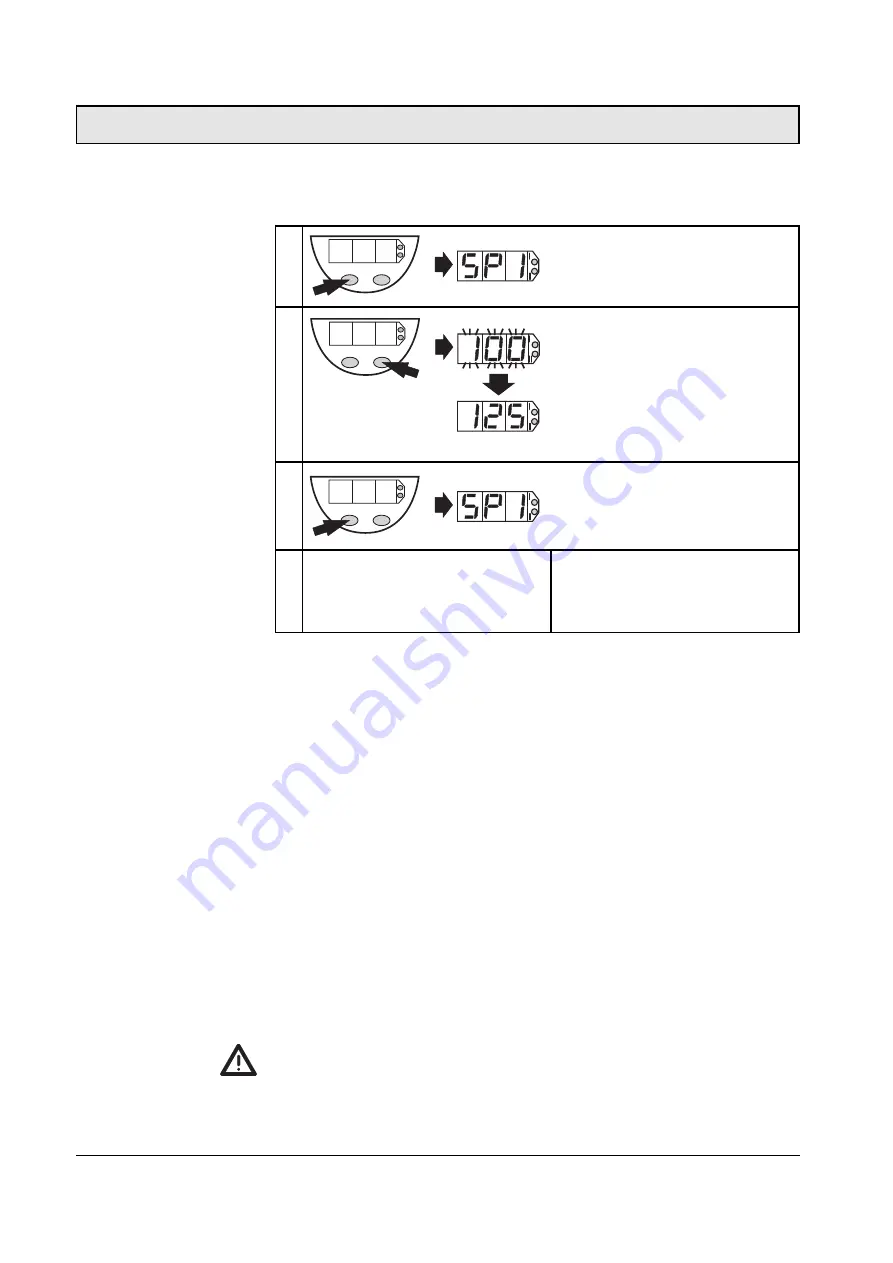

1

Mode/Enter Set

Mode/Enter Set

Mode/Enter Set

Press the

Mode/Enter

button

several times until the

respective

parameter

is displayed.

the

Set

button and keep

it pressed. The current

parameter

value flashes

for 5s,

then

the value

is increased

*

(incremental by pressing briefly or

scrolling by holding pressed).

Press the

Mode/Enter

button

briefly

(= acknowledgement).

The parameter is displayed again,

the set parameter value becomes

effective.

2

3

4

Change more parameters:

Start again with step 1.

Finish programming:

Wait for 15s or press the

Mode/Enter button until the current

measured value is indicated again..

*Decrease the value: Let the display of the parameter value move to the

maximum setting value. Then the cycle starts again at the minimum setting

value.

Select the

display unit

(bar, PSI, Pa)

before

setting the switch points (SPx,

rPx) or the limits for the analog output signal (ASP, AEP). This avoids rounding

errors generated internally during the conversion of the units and enables

exact setting of the values.