43

UK

11.7 Simulation

11.7.1 Set simulation value

►

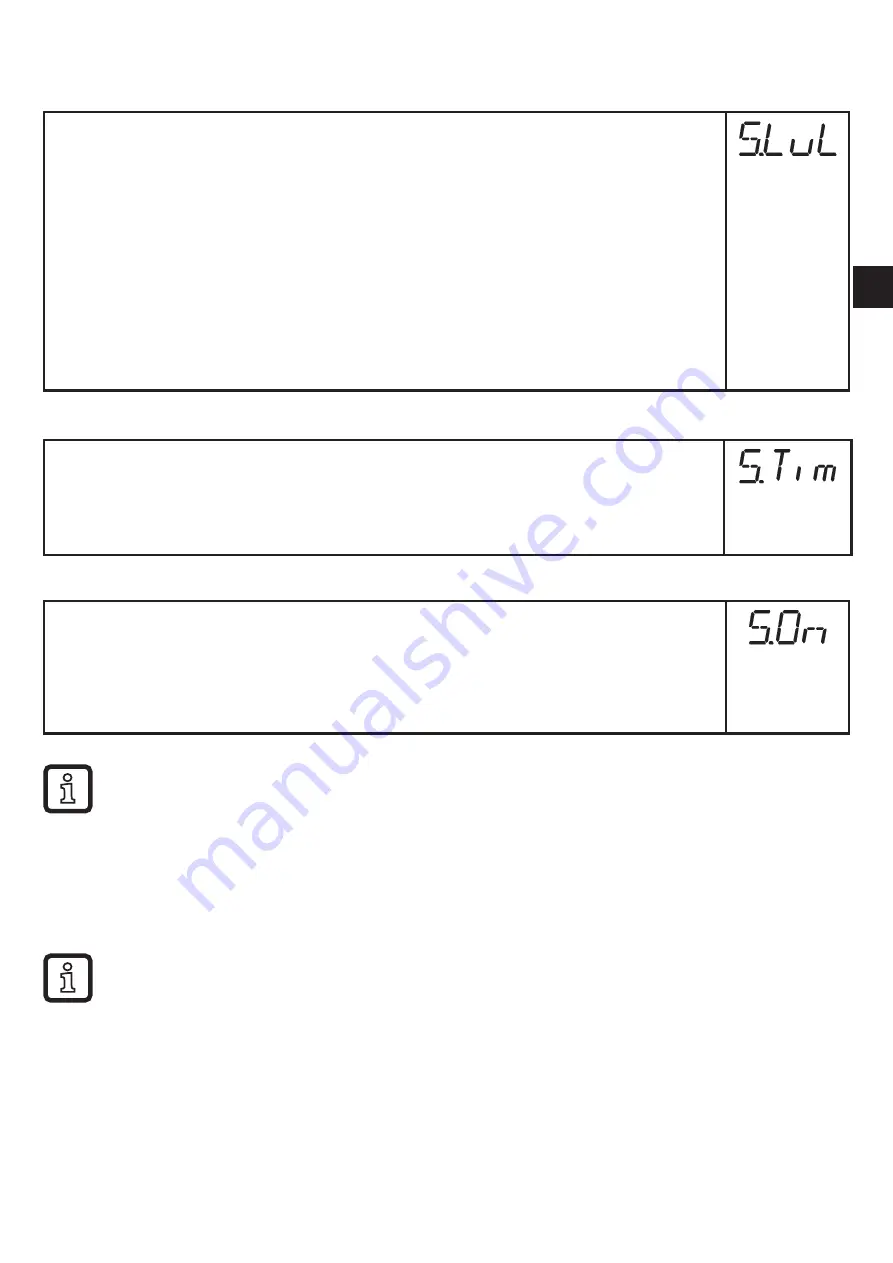

Select [S.LvL].

► Set the process value to be simulated:

[Numerical

value] =

level in mm

[FULL] =

full state

[SEnS] =

weak measured signal

[Err] =

electronic fault found

[EPTY] =

empty state

►

Press [Enter].

11.7.2 Set simulation duration

►

Select [S.Tim].

►

Set time span for simulation.

Setting range: 1, 2, 3, 4, 5, 10, 15, 20, 30, 45, 60 min.

Factory setting: 3 min.

11.7.3 Switch simulation on / off

► Select [S.On] and set:

[OFF] =

simulation off

[On] =

simulation on

►

Press [Enter] to start the simulation.

Simulation active until [Enter] is pressed again or the time set via [S.Tim] elapses.

During the simulation [SIM] is displayed every 3 s.

After the simulation the unit returns to the parameter [S.On] and internally the unit

returns to the operating mode (and the process value transmission).

After another 30 s the display changes to the process value display.

The outputs react according to the simulated process values.

If the simulation is started via IO-Link, it can also only be finished via IO-Link. During

the attempt to finish the simulation via the buttons, C.Loc is displayed.