Module 68

Operating instructions

25 - 38

IEF-Werner GmbH | Wendelhofstraße 6 | DE-78120 Furtwangen | www.ief-werner.de

Er

st

el

lt v

on

: F

ran

k R

ei

ch

el

t

|

MA

N

_E

N

_1040579_

Mo

d

ul

e 68_

R

2f

.d

oc

5

Maintenance and Repair

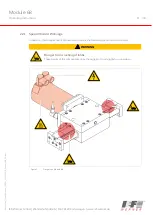

DANGER

Warning of dangerous electrical voltage.

The system must be powered down for all assembly, disassembly or repair work.

Non-observance of the safety provisions may cause death.

CAUTION

Repairs by specialist personnel only.

Any repairs must only be performed by specialist personnel who have read and

understood these original operating instructions.

Only use genuine spare parts, since IEF-Werner GmbH will not assume any warranty

otherwise.

5.1

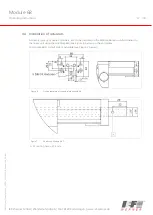

Lubrication of guide carriage

During the design of the linear units Module 68 and Module 68 D, great importance was placed on

the use of low-maintenance components.

All roller elements were provided with lifetime lubrication in the factory.

To avoid danger of over-lubrication of the linear bearings, no external lubrication nipples were

attached to the carriage part.

However, to achieve a high service life of the dirt wipers, we recommend lubricating the guide

shafts with special grease at regular intervals. The lubricant may be procured from IEF in tubes of

50 gr (part no.729148) each.

The recommended maintenance intervals add up to approx. 200 operating hours under regular

ambience conditions. The maintenance intervals should be reduced under difficult ambient

conditions.

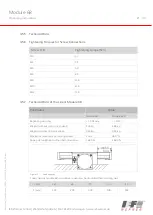

5.2

Tooth belt tension

The toothed belt tension for module 68 is set with spacer ring.

■

See chapter Module 68, TG1000018, Installation variant 1,

30 and

■

Module 68, TG1000018, installation variants 2 and 3,

5.3

Belt tension gear toothed belt

The belt tension of the gear toothed belt should be 150 N.

■

See chapter Module 68 gearbox, TG 1000032,

36, drawing item 20.