BLENDORAMA III

12

3.3

Maintenance

3.3.1

Blendorama Maintenance Kit

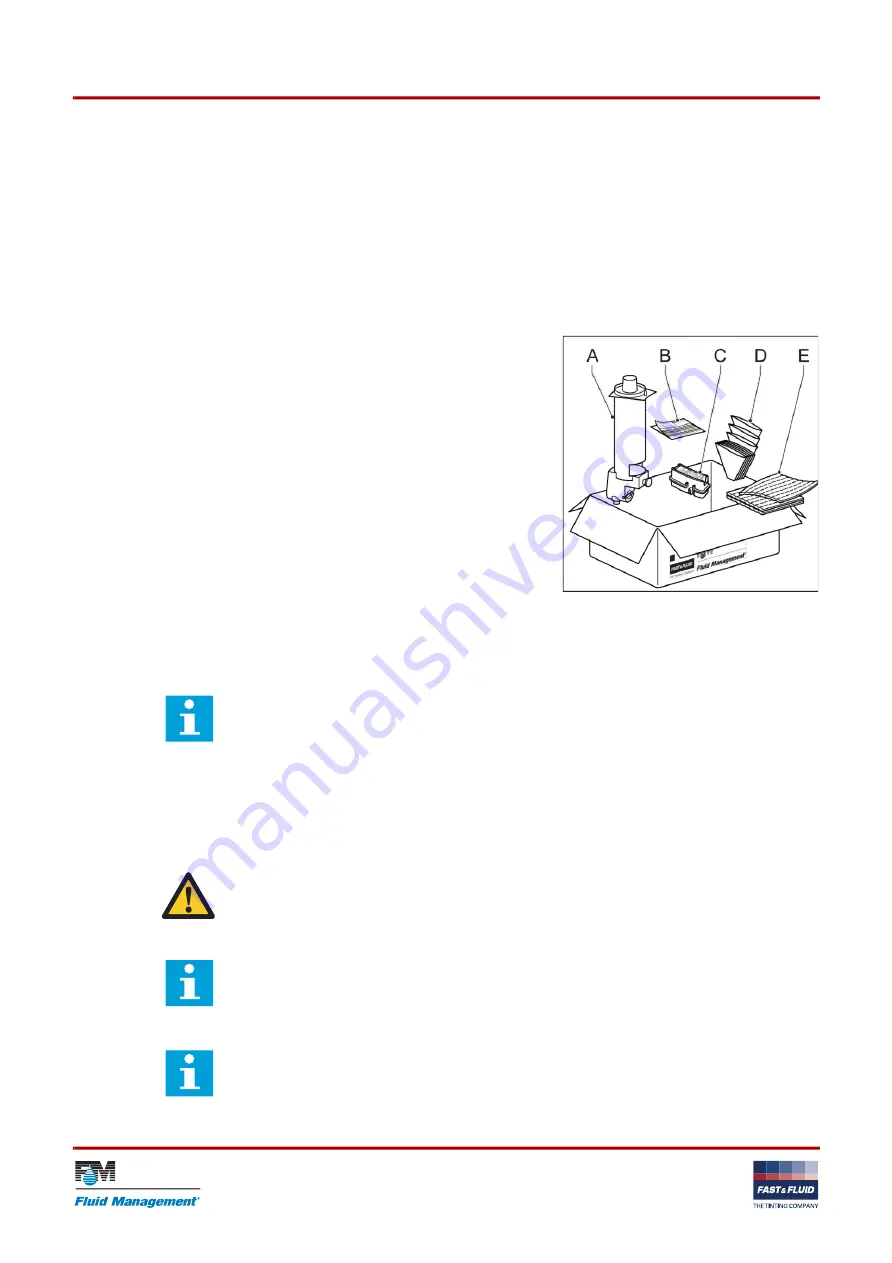

To keep your Blendorama in optimal condition, we highly recommend you to use the Blendorama Maintenance

Kit. The Blendorama Maintenance Kit contains everything you need to keep your machine in optimal condition

for the period of 1 year.

A:

Replacement canister with pump (1x)

B:

Blendorama schedule sticker (1x)

C:

Replacement brush unit (3x)

D:

Paper funnel (200x)

E:

Blendorama cleaning cloth (3x)

-

The replacement canister with pump (A) should be used as a

spare part and can be used whenever one of the canisters

needs to be replaced.

-

The Blendorama schedule sticker (B) gives you a clear

overview of the maintenance tasks and a reminder to keep

your machine in optimal condition.

-

Replace the brush unit (C) every 4 months for optimal

performance.

-

Use the Blendorama paper funnels (D) for the clean filling and refilling of the canisters.

-

Use the Blendorama cleaning cloth (E) with a non-organic cleaning liquid to clean the machine and the

nozzles.

Note

The Blendorama Maintenance Kit is available through

your machine supplier.

3.3.2

General cleaning: daily

1. Clean the machine with a damp Blendorama cleaning cloth and remove all spilled colorant or

other fluids.

CAUTION

Do not use cleaning agents based on organic solvents

to clean plastic parts of the machine.

Note

Remove spilled colorant and other fluids as soon

as possible.

Note

Do not drain spilled colorant or other fluids in the

sink. Observe the local regulations.

Содержание Blendorama III Series

Страница 1: ...Original Manual of www fluidman com V 1 0 www fast fluid com...

Страница 24: ...6 7 Electrical diagram 244...