25

Installation and Servicing

SECTION 2 - INSTALLATION

INST

ALLA

TION

2.11 CONDENSATE DRAIN

T

his appliance is fitted with a siphonic 75mm condensate trap

system that requires filling before operating the appliance for the

1st time or after maintenance.

All condensate pipework should conform to the following:

a. Where a new or replacement boiler is being installed, access to

an internal ‘gravity discharge’ termination should be one of the

main factors considered in determining boiler location.

b. Plastic with push fit or solvent connections.

c. Internal plastic pipe work a minimum of 19mm ID (typically

22mm OD)

d. External plastic pipe must be a minimum of 30mm ID (typically

32 OD) before it passes through the sleeved wall.

e. All horizontal pipe runs, must fall a minimum of 45mm per metre

away from the Boiler.

f. External & unheated pipe work should be kept to a minimum

and insulated with Class “O” waterproof pipe insulation.

g. All installations must be carried out in accordance to the

relevant connection methods as shown in the “Condensate

installation diagrams” & BS6798.

h. Pipe work must be installed so that it does not allow spillage

into the dwelling in the event of a blockage (through freezing)

i. All internal burrs should be removed from the pipe work and any

fittings.

In order to minimise the risk of freezing during prolonged very cold

spells, one of the following methods of terminating condensate

drainage pipe should be adopted.

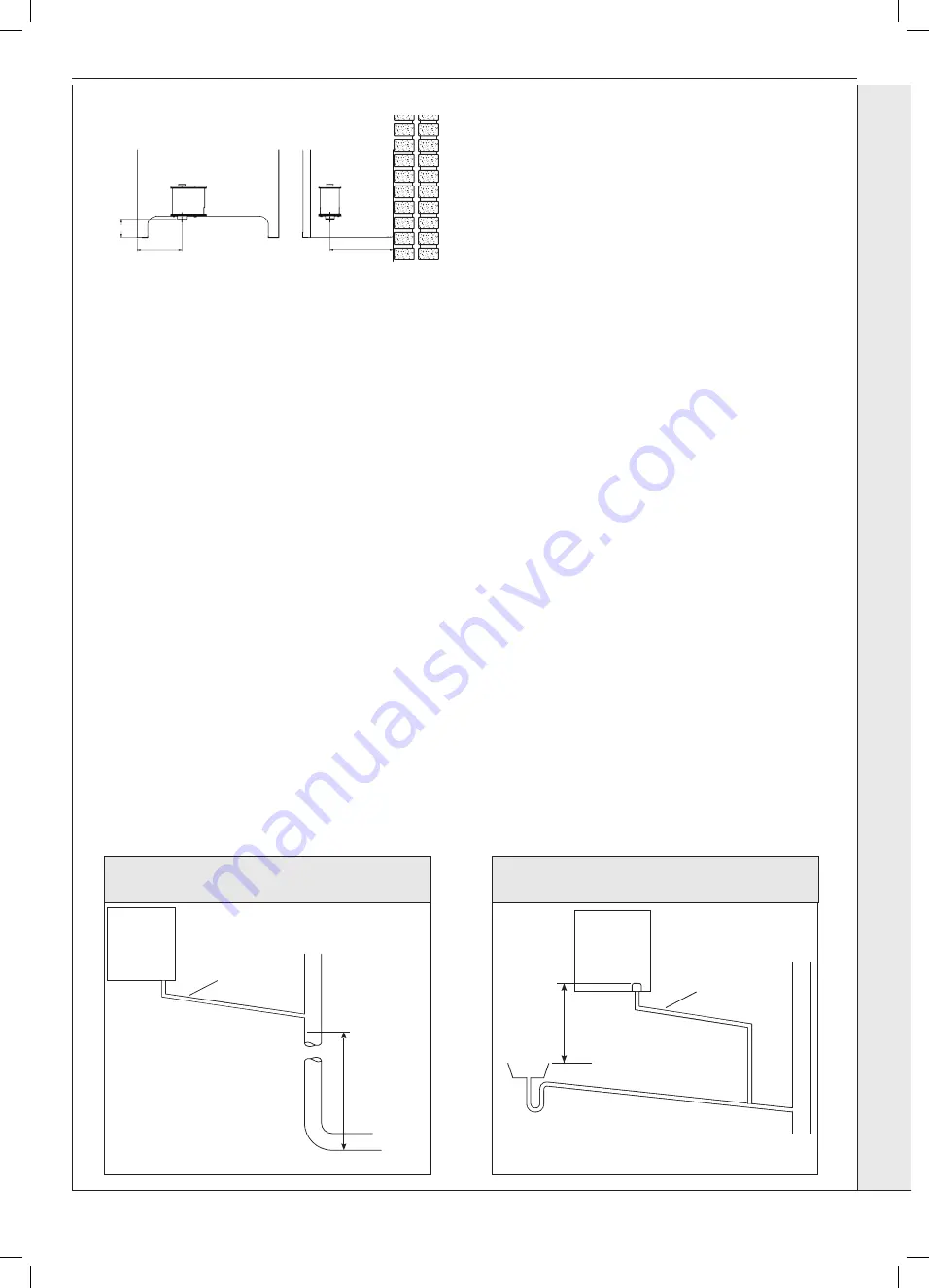

Internal Drain Connections

Wherever possible, the condensate drainage pipe should be routed

to drain by gravity to a suitable internal foul water discharge point

such as an internal soil and vent stack or kitchen or bathroom

waste pipe etc. See Figs 1 and 2.

Note

. For installations where the PRV is required to terminate

into the Condensate Drain Pipe, a proprietary termination and

back flow prevention kit MUST be purchased separately from a

plumbers merchant. The installation instructions for the kit MUST

be followed.

Condensate Pump

Where gravity discharge to an internal termination is not physically

possible or where very long internal pipe runs would be required

to reach a suitable discharge point, a condensate pump of a

specification recommended by the boiler or pump manufacturer

should be used terminating into a suitable internal foul water

discharge point such as an internal soil and vent stack or internal

kitchen or bathroom waste pipe etc. (fig 3).

External Drain Connections

The use of an externally run condensate drainage pipe should

only be considered after exhausting all internal termination options

as described previously. An external system must terminate at a

suitable foul water discharge point or purpose designed soak away.

If an external system is chosen then the following measures must

be adopted:

The external pipe run should be kept to a minimum using the most

direct and “most vertical” route possible to the discharge point, with

no horizontal sections in which condensate might collect.

-

For connections to an external soil/vent stack see Fig 4.

Insulation measures as described should be used.

-

When a rainwater downpipe is used, an air break must be

installed between the condensate drainage pipe and the

downpipe to avoid reverse flow of rainwater into the boiler

should the downpipe become flooded or frozen, see Fig 5.

-

Where the condensate drain pipe terminates in a purpose

designed soak away (see BS 6798) any above ground

condensate drain pipe sections should be run and insulated as

described above. See Fig 6.

-

Where the condensate drain pipe terminates over an open

foul drain or gully, the pipe should terminate below the grating

level, but above water level, to minimise “wind chill” at the open

end. The use of a drain cover (as used to prevent blockage by

leaves) may offer further prevention from wind chill.

Unheated Internal Areas

Internal condensate drain pipes run in unheated areas, e.g. lofts

basements and garages, should be treated as external pipe.

Ensure the customer is aware of the effects created by a frozen

condensate and is shown where this information can be found in

the user manual.

Condensate

Drain

Condensate

Drain

199

140

58

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Minimum

connection

height up to 3

storeys

Soil & vent stack

≥ 450

Sink/basin/

bath or

shower

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Internal soil & vent stack

≥ 100

Figure 1

- Connection of Condensate Drainage Pipe to

Internal Soil & Vent Stack

Figure 2

- Connection of a Condensate Drainage Pipe

Downstream of a Sink, Basin, Bath or Shower Water Trap to

Internal Soil Vent Stack

continued . . . . .

Содержание VOGUE MAX COMBI 26

Страница 4: ...4 Installation and Servicing...

Страница 6: ...6 Installation and Servicing...

Страница 74: ......