29

Henrad SE FF

- Installation

INSTALLATION

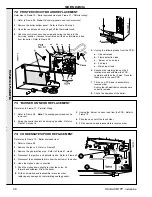

B. Gas Installation

1. The whole of the gas installation, including the meter, should be

inspected and tested for soundness and purged in accordance

with the recommendations of BS. 6891.

2. Purge air from the gas installation by loosening the gas cock

union and purge until gas is smelled.

3. Retighten the union and test for gas soundness.

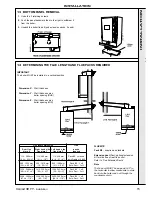

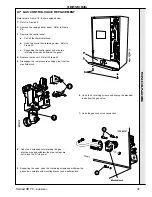

45 GAS CONNECTION

INST

ALLA

TION

WA

RNING.

Whilst effecting the required gas soundness test and purging air from the gas

installation, open all windows and doors, extinguish naked lights and DO NOT SMOKE.

Refer to Frame 2 for details of the position of the gas connection.

A MINIMUM working gas pressure of 20 mbar (8" w.g.) must be

available at the boiler inlet with the boiler firing. Refer to Frame

47 or 'Servicing' for details of the pressure test point position.

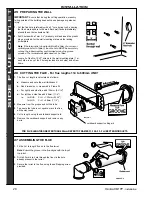

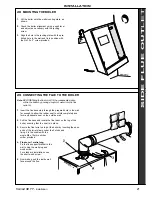

Extend a gas supply pipe NOT LESS THAN 15mm O.D. to the

boiler and connect to the gas service cock, situated at the

bottom right hand side of the boiler.

The connection MUST be from the RHS rear of the boiler and

from either ABOVE or BELOW.

Do not route the pipe behind

the control box.

A. Electrical Installation

1. Checks to ensure electrical safety should be carried out by a

competent person.

2. ALWAYS carry out the preliminary electrical system checks, i.e.

earth continuity, polarity, resistance to earth and short circuit, using

a suitable test meter.

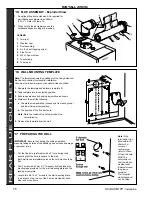

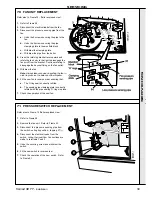

46 COMMISSIONING AND TESTING

Ensure that the gas supply pipe does not foul the boiler casing.

Note.

If the pipe run from the meter to the boiler is greater than

3m (10') 22mm O.D. pipe must be used.

To facilitate connection, it is recommended that the gas service

cock is not removed from the gas control valve.

A 1/2" BSP x 15mm connector, pre-fitted with a short stub

connection, should be screwed into the cock, using a suitable

sealant.

IMPORTANT. The gas service cock contains a non-metallic seal

so must not be overheated when making capillary connections.

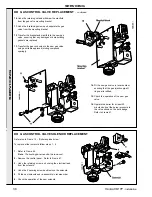

47 INITIAL LIGHTING

plastic cover and turn the screw CLOCKWISE to

reduce the

pressure or ANTICLOCKWISE to

increase the pressure. Refit

the cover.

15. Set the thermostat knob (B) to OFF.

16. Switch the electricity supply OFF.

17. Remove the pressure gauge and tube. Replace the sealing

screw in the pressure test point. Ensure a gas tight seal is

made.

18. Refit the boiler front and bottom panels, using the screws

previously removed.

19. Close the controls pod door.

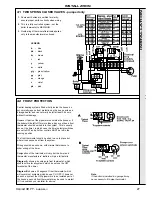

LEGEND

A

'Burner on' neon

B

Thermostat knob

C

Gas service cock

D

Inlet pressure test point

E

Burner pressure test point

F

Burner pressure adjuster

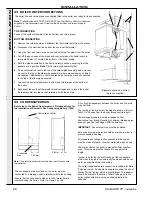

1.

Check that the system has been filled and that the boiler is not air locked

- air in the system could trip the dry fire ''stat (H)

2.

Check that all the drain cocks are closed and any valves in the flow and

return are open.

3.

Check that the electrical supply is OFF.

4.

Check that the flue 'stat (L) is calling for heat - press the reset button.

5.

Refit the boiler sealing panel - refer to Frame 21.

6.

Check that the gas service cock (C) is ON and that the boiler thermostat

knob (B) is OFF.

7.

Check that the dry fire thermostat (H) and overheat thermostat (J) are

calling for heat - press the reset buttons.

8.

Remove the screw in the burner pressure test point (E) and connect a

gas pressure gauge via a flexible tube.

9.

Switch the electricity supply ON and check that all external controls are

calling for heat.

10. Set the boiler thermostat knob (B) to position 6. The gas control solenoid

valve should open and the spark commence, continuing until the burner

is established.

11. Check that the burner lights smoothly and that the 'Burner on' neon

(A) illuminates. If this does not occur within 10 seconds, turn the

thermostat knob to OFF, wait for 5 seconds then repeat step 10.

If the burner still does not light refer to the 'Fault Finding' section.

12. Test for gas soundness around ALL boiler gas components, using leak

detection fluid.

13. Operate the boiler for 20 minutes to stabilise the burner temperature.

14. The boiler is spot rated. Check that the burner pressure corresponds to

the setting given on the data badge, located at the RHS of the boiler

casing. Adjust as necessary via the adjuster screw (F). Prise aside the

G

Fan pressure test point (Hi)

H

Dry fire thermostat reset button

I

Fan pressure test point (Lo)

J

Overheat thermostat reset button

K

Flue gas sampling point

L

Flue 'stat reset button (behind sealing panel)

Note.

The boiler is shown with the front panel

removed and the controls drop-down door open.

Содержание Henrad SE 30 FF

Страница 1: ......

Страница 2: ...2 Henrad SE FF Installation ...