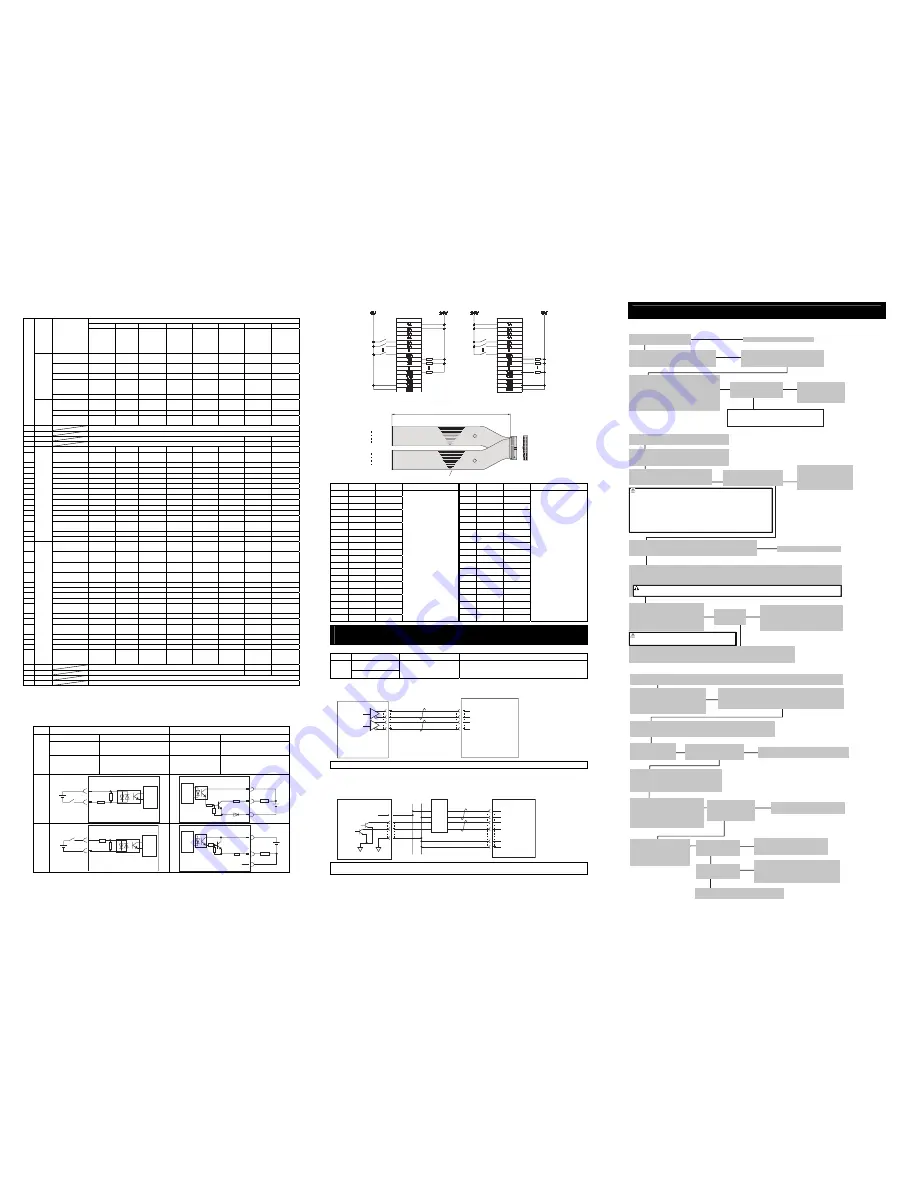

Signal Assignment for Each Mode

The signal assignment of I/O flat cable by the PIO pattern is as shown below. Follow the following table to connect the external

equipment (such as PLC).

Selection in Parameter No. 25 (PIO Pattern)

0 1 2 3 4 5 6

Category PIO

Functions

Positioning

mode

Teaching

mode

256-point

mode

512-point

mode

Electro-

magnetic

valve mode

1

Electro-

magnetic

valve mode

2

Pulse train

control mode

(For

Incremental )

Pulse train

control mode

(For

Battery-less

Absolute

Number of

Positioning Points

64 points

64 points

256 points

512 points

7 points 3

points

–

–

Home Return

Signal

{

{

{

{

{

×

{

{

Jog Signal

×

{

×

×

×

×

×

×

Teaching Signal

(Current Position

Writing)

×

{

×

×

×

×

×

×

Input

Brake Release

{

×

{

{

{

{

{

{

Signal during

Operation

{

{

×

×

×

×

×

×

Zone Signal

{

Δ

(Note1)

Δ

(Note1)

×

{

{

{

{

Pin

No.

Output

Position Zone

Signal

{

{

{

×

{

{

×

×

1A 24V

P24

2A 24V

P24

3A –

–

PP

PP

4A –

–

/PP

/PP

5A IN0

PC1

PC1

PC1

PC1

ST0

ST0

SON

SON

6A IN1

PC2

PC2

PC2

PC2

ST1

ST1

(JOG

+

)

RES RES

7A IN2

PC4

PC4

PC4

PC4

ST2

ST2

(Note2)

HOME HOME

8A IN3

PC8

PC8

PC8

PC8

ST3

–

TL

TL

9A IN4

PC16

PC16

PC16

PC16

ST4

–

CSTP

CSTP

10A IN5

PC32

PC32

PC32

PC32

ST5

–

DCLR

DCLR

11A IN6

–

MODE

PC64

PC64

ST6

–

BKRL

BKRL

12A IN7

–

JISL

PC128

P128

–

–

RMOD

RMOD

13A IN8

–

JOG

+

–

PC256

– – –

RSTR

14A IN9

BKRL

JOG

−

BKRL BKRL BKRL BKRL –

–

15A IN10

RMOD

RMOD

RMOD

RMOD

RMOD

RMOD

–

–

16A IN11

HOME

HOME

HOME

HOME

HOME

–

–

–

17A IN12

*STP

*STP

*STP

*STP

*STP

–

–

–

18A IN13

CSTR

CSTR/PW

RT

CSTR

CSTR

– – – –

19A IN14

RES

RES

RES

RES

RES

RES

–

–

20A

Input

IN15 SON

SON

SON

SON

SON

SON – –

1B OUT0

PM1

(ALM1)

PM1

(ALM1)

PM1

(ALM1)

PM1

(ALM1)

PE0 LS0 PWR PWR

2B OUT1

PM2

(ALM2)

PM2

(ALM2)

PM2

(ALM2)

PM2

(ALM2)

PE1

LS1

(TRQS)

SV SV

3B OUT2

PM4

(ALM4)

PM4

(ALM4)

PM4

(ALM4)

PM4

(ALM4)

PE2

LS2

(Note2)

INP INP

4B OUT3

PM8

(ALM8)

PM8

(ALM8)

PM8

(ALM8)

PM8

(ALM8)

PE3 – HEND

HEND

5B OUT4

PM16

PM16

PM16

PM16

PE4

–

TLR

TLR

6B OUT5

PM32

PM32

PM32

PM32

PE5

–

*ALM

*ALM

7B OUT6

MOVE

MOVE

PM64

PM64

PE6

–

*EMGS

*EMGS

8B OUT7

ZONE1

MODES

PM128

PM128

ZONE1

ZONE1

RMDS

RMDS

9B OUT8

PZONE/

ZONE2

PZONE/

ZONE1

PZONE/

ZONE1

PM256

PZONE/

ZONE2

PZONE/

ZONE2

ALM1 ALM1

10B OUT9

RMDS

RMDS

RMDS

RMDS

RMDS

RMDS

ALM2

ALM2

11B OUT10

HEND

HEND

HEND

HEND

HEND

HEND

ALM4

ALM4

12B OUT11

PEND

PEND/

WEND

PEND PEND PEND – ALM8 ALM8

13B OUT12

SV

SV

SV

SV

SV

SV

*ALML

*ALML

14B OUT13

*EMGS

*EMGS

*EMGS

*EMGS

*EMGS

*EMGS

–

REND

15B

OUT14 *ALM *ALM *ALM *ALM *ALM *ALM ZONE1 ZONE1

16B

Output

OUT15

(Note3)

LOAD/TRQS

*ALML

/*BALM

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

LOAD/TRQS

*ALML

/*BALM

*BALM/

*ALML

ZONE2 ZONE2

17B –

–

NP

NP

18B –

–

/NP

/NP

19B 0V

N

20B 0V

N

(Note) “*” in codes above shows the signal of the active low.

PM1 to PM8 indicate the alarm binary code output signal when an alarm is generated. [Refer to the Instruction Manual

for the details]

(Note 1) The setting can be changed over to PZONE if set in the parameter setting.

(Note 2) It is invalid before home-return operation.

(Note 3) *BALM is dedicated for ACON.

PIO Input and Output Interface

Input section

Output section

Input voltage

24V DC

±

10%

Load voltage

24V DC

Input current

5mA 1 circuit

Peak load electric

current

50mA/1 point

S

pecifi

ca

tion

ON/OFF voltage

ON voltage MIN. 18V DC

OFF voltage MAX. 6V DC

Leak Current

MAX. 2mA/1 point (PCON)

MAX. 1mA/1 point

(ACON, DCON)

NP

N

680

5.6K

P24

External

Power Supply

24V DC

Input

Terminal

Internal

Power

Source

Controller

15

P24

N

Load

External

Power Supply

24V DC

Output

Terminal

Internal

Power

Source

Controller

PNP

680

5.6K

N

External

Power Supply

24V DC

Input

Terminal

Internal

Power

Source

Controller

15

P24

N

Load

External

Power Supply

24V DC

Output

Terminal

Internal

Power

Source

Controller

NPN Specification

PNP Specification

I/O Cable

Model

:

CB-PAC-PIO

□□□

(Enter the cable length (L) in

□□□

Example. 020

=

2m)

No. Signal Name Cable Color

Wiring

No.

Signal Name Cable Color

Wiring

1A 24V BR-1

1B OUT0 BR-3

2A 24V RD-1

2B OUT1 RD-3

3A PP OR-1

3B

OUT2 OR-3

4A /PP YW-1

4B

OUT3 YW-3

5A IN0 GN-1

5B

OUT4 GN-3

6A IN1 BL-1

6B

OUT5 BL-3

7A IN2 PL-1

7B

OUT6 PL-3

8A IN3 GY-1

8B

OUT7 GY-3

9A IN4 WT-1

9B

OUT8 WT-3

10A IN5 BK-1

10B

OUT9 BK-3

11A IN6 BR-2

11B

OUT10 BR-4

12A IN7 RD-2

12B

OUT11 RD-4

13A IN8 OR-2

13B

OUT12 OR-4

14A IN9 YW-2

14B

OUT13 YW-4

15A IN10 GN-2

15B

OUT14 GN-4

16A IN11 BL-2

16B

OUT15 BL-4

17A IN12 PL-2

17B

NP

PL-4

18A IN13 GY-2

18B

/NP

GY-4

19A IN14 WT-2

19B

0V

WT-4

20A IN15 BK-2

Flat Cable

○

A

(Insulation-Displacement

Connectors)

AWG28

20B

0V BK-4

Flat Cable

○

B

(Insulation-Displacement

Connectors)

AWG28

Operation in Pulse Train Control Mode

(function for PLN and PLP Types only)

Pulse Train Input and Output Interface

Category Abbreviated Code

Signal Name

Contents of Functions

PP, /PP

Input

NP, /NP

Command Pulse Input

Inputs the command pulse train.

Input pulse frequency differs depending on the type.

[Refer to Basic Specifications]

●

When Host Unit is Differential System

(Although the example shows PCON, it is the same for ACON and DCON.)

Note1 : Use the same power source (0V) for the host open collector output, AK-04.

●

When Host Unit is Open Collector System [AK-04 (option) is required]

(Although the example shows PCON, it is the same for ACON and DCON.)

Note1 : 1) Use the same power source (0V) for the host open collector output, AK-04.

2) Have the cables as short as possible between the host unit and AK-04.

Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by referring to

the procedure below. “PC” stated in this section means “PC software”.

Pin No.

Pin No.

Load

Load

Flat Cable (20-core)

×

2

BK-4

BR-3

BK-2

BR-1

No treatment

conducted

No treatment

conducted

20A

20B

1A

1B

Half Pitch MIL Socket

HIF6-40D-1.27R (Hirose Electric)

A

B

L

0V

24V

DC

0V

0V

1

2

3

4

1

2

3

4

PCON

PIO Connector

3A

4A

17B

18B

19B

20B

Host Unit

Positioning Unit

Pulse

Command

0V

0V

PP

/PP

NP

/NP

/PP

PP

NP

/NP

NP

PP

0V

24V

Pulse Converter

AK-04

(to be purchased separately)

24V

PCON

PIO Connector

3A

4A

17B

18B

Host Unit

Positioning Unit

Pulse Command

(Line Driver:

26C31 or equiv.)

PP

/PP

NP

/NP

→

No →

Contact us or our distributor.

↓ Yes

No →

→

↓ Yes

← Yes

→

No →

Check Item

Is the Controller Status Display

LED turned ON in green [SV]?

Check the emergency stop circuit.

→

No →

↓ Yes

↓ Yes

↓

Check if there is any problem with the

installation of the actuator and the condition

of the actuator use exceeds the ranges of the

rated values.

Adjust the servo if necessary.

If an alarm is generated,

connect the PC or teaching

pendant and check the

content of the alarm to have

the right treatment.

Check Item

Any vibration or

abnormal noise?

No →

↓ Yes

Point Check Item

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

Check Item

Is the Controller Status

Display LED turned OFF?

Connect the teaching tool

such as PC to confirm the

content of alarm and have

an appropriate treatment.

Have the settings and checks suitable for the used

mode selected from “Positioner Mode” and “Pulse

Train Control Mode” below.

[In the case of Positioner Mode]

Check of Packed Items

Are there all the delivered items?

Installation and Wiring

Perform the installation of and wiring for the

actuator and controller.

Power Supply and Alarm Check

Connect a teaching tool such as PC, turn the

operation mode setting switch to “MANU” side and

turn the power ON for unit.

Select [Teaching Mode 1 Safety Speed Activated /

PIO Operation Invalid] in the teaching tool such as

PC.

PIO Pattern Settings

Set the used PIO pattern to Parameter No.25.

Safety Speed Setting

Set the Parameter No.35 if necessary.

The safety speed is set to 100mm/s at the delivery.

Servo ON

Turn the servo ON with the operation on the

teaching tool such as PC.

Caution

Please perform this process with the actuator away from the mechanical end or

interfering subjects as much as possible.

Put the actuator away if it interferes with surroundings. It may generate an alarm

if the actuator hit the mechanical end or interfering subjects when the servo is

turned ON.

The slider may get slightly dropped by self-weight if servo ON and OFF is

repeatedly performed at the same position. Be careful not to pinch the hand or

damage the work.

Safety Circuit Check

Does the emergency stop circuit (drive cutoff circuit) work properly and

turn the servo OFF?

Target Position Setting

Set the target position in “Position” Box in each position table.

Perform a home-return operation first when Direct Teaching is to be performed. When moving the actuator manually, set

the Brake Release Switch to “BK RLS” side for the brake equipped type. Put the switch back after the setting is complete.

Test Run Adjustment 1

Check the operation without mounting a

work and set the safety speed invalid on

the teaching tool such as PC, and then

check the operation with a work mounted.

Caution To ensure safety, it is recommended that safety

speed be enabled during initial movements.

Test Run Adjustment 2

1) Set the operation mode setting switch to “AUTO”.

2) Output the operation command from PLC to the controller and check the system operation.

Warning Be careful not to pinch fingers or damage the work with the dropped actuator when releasing the brake

in vertical orientation.

→

Check Item

Is the minimum unit of operation set to the value bigger than the

minimum resolution of the encoder?

Is the fraction of the electronic gear ratio reduced to its lowest terms?

← Yes

→

Check Item

Is the Controller Status Display

LED turned ON in green [SV]?

No → Confirm the content of alarm on the teaching

tool such as PC to have an appropriate treatment.

← Yes

↓ Yes

→

No →

No → Check the electronic gear ratio setting.

Confirm the command pulse train input

mode setting.

Confirm that there is no problem in the

actuator installation, the actuator operation

condition demands a voltage more than rated

voltage, and appropriate pulse trains are input.

Check if there is any problem in the way

of actuator mount.

Check Item

Is there any risk of

interfering with peripheral

equipment?

No →

↓ Yes

Can the positioning

operation be performed

normally?

↓ Yes

↓ Yes

Is it in condition without

any vibration and

abnormal noise?

Test Run Adjustment 3

Check the system operation conducted by PLC.

PIO Pattern Settings

Set the used 6 “Pulse train control mode” or 7 “Pulse train control mode for Battery-less Absolute” to Parameter No.25.

Set the Electronic Gear

[Refer to Instruction Manual]

Set the electronic gear ratio based on the

amount of actuator operation per pulse in

Parameters No.65 and 66.

Pulse Train Input Output Mode Setting [Refer to Instruction Manual]

Set the command pulse train input status for the parameter No.63 and No.64.

Put Operation Mode Setting Switch to “AUTO” side when the setting is complete.

Servo ON

Input servo ON signal

from PLC.

Safety Circuit Check

Check that the emergency stop circuit (or motor

drive-power cutoff circuit) operates normally to turn

OFF the servo.

Test Run Adjustment 1

[Operation Mode MANU]

Check with a teaching tool such as the

PC software with no work being loaded,

and check the operation range with JOG

operation with the work being loaded.

Test Run Adjustment 2

[Operation Mode AUTO]

Output the pulse train from PLC

to the controller and check the

system operation.

[In the case of Pulse Train Control Mode (for PLN and PLP types only)]