WARNING

Always wear the proper protective equipment in-

cluding eye protection and petroleum-resistant

gloves when handling hydraulic oil. Thoroughly

wash oil from exposed areas of skin as soon as

possible.

The hydraulic oil is hot at normal operating tem-

peratures. Be careful when draining the oil.

Never check for leaks by putting hands on hy-

draulic lines or components under pressure. Hy-

draulic oil under pressure can be injected into the

skin.

CAUTION

Protect the hydraulic system from dirt and con-

taminants when servicing the hydraulic system.

NOTE:

Tag hydraulic lines prior to disconnecting

to insure correct connection during installation.

NOTE:

If lift truck is equipped with quick discon-

nect hoses, see section Disconnecting Attachment

Hydraulic Quick Disconnect Hoses.

2.

Disconnect the hydraulic lines at the sideshift

cylinder. Put caps on the open hydraulic lines.

3.

Remove the lower mounting hooks by removing

the four capscrews securing the hooks.

4.

Remove two hairpins, two pins, and sideshift

cylinder from the carriage.

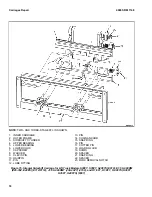

See Figure 14 for lift truck models

• S2.0-3.5FT (S40-70FT, S55FTS) (F187)

• H2.0-3.5FT (H40-70FT) (L177)

• J2.00-3.20XM (J40-65Z) (B416)

• E2.00-3.20XM (E45-65Z) (G108)

See Figure 15 for lift truck models

• S30FT, S35FT, S40FTS (E010)

• E1.50-2.00XM (E25-35Z, E40ZS) (E114/

F114)

• J1.60-2.00XMT (J30-40ZT) (J160)

• H1.6FT, H1.8FT, H2.0FTS (H30FT,

H35FT, H40FTS) (F001)

5.

Use a crane with a capacity of at least

450 kg (992 lb) to lift the outer frame away

from the inner carriage. Lay the outer frame

flat on a pallet or workbench.

Clean and Inspect

1.

Inspect the lower mounting hooks for wear. Re-

place the hooks if they are worn beyond the

wear limit. The wear limit clearance range is

0.76

mm

(0.03

in.)

minimum

and

1.52 mm (0.06 in.) maximum. See A in Fig-

ure 16.

A.

WEAR LIMIT - 0.76 mm (0.03 in.) MINIMUM AND

1.52 mm (0.06 in.) MAXIMUM.

B.

CLEARANCE ADJUSTMENT - 0.76 mm (0.03 in.)

MINIMUM AND 1.52 mm (0.06 in.) MAXIMUM.

Figure 16. Lower Mounting Hooks Wear Limit and

Clearance Adjustment

2.

Clean and inspect the carriage bars for damage

and smoothness. Ensure the bars are parallel

and the ends are flush.

3.

Clean the bearing areas. Inspect the sideshift

bearings for wear as follows:

a.

Remove the upper bearings from the upper

apron. If either upper bearing is worn to less

than 2.5 mm (0.1 in.) thickness, replace both

upper bearings by driving the upper bearings

from the upper apron.

4000 SRM 1148

Carriages Repair

19

Содержание J160

Страница 1: ...Hyster J160 J30ZT J35ZT J40ZT Forklift...