Table 1. Fork Tip Alignment

Fork Tip Alignment Specifications

Standard Fork

Lengths

Maximum Fork Tip

Difference

1

mm

(in.)

mm

(in.)

914

(36)

27

(1.08)

1067

(42)

32

(1.26)

1219

(48)

37

(1.44)

1372

(54)

41

(1.62)

1524

(60)

46

(1.80)

1829

(72)

55

(2.16)

1

Difference of alignment between fork tips must be

no more than 3% of the total fork length.

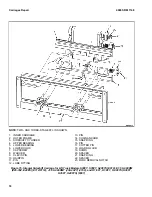

A.

HEEL OF FORK (MUST BE 90% OF DIMEN-

SION B)

B.

ORIGINAL FORK THICKNESS (DIMENSION B)

1. TIP ALIGNMENT (MUST BE WITHIN 3% OF

FORK LENGTH)

2. CRACKS

3. MAXIMUM ANGLE 93°

4. FORK REMOVAL NOTCH

5. CARRIAGE

Figure 8. Fork Check

3.

Check that the bottom of each fork is not exces-

sively worn.

4.

Check for smooth and proper operation of the

fork lock pins. Repair or replace any damaged

or broken fork lock pins or components and lu-

bricate, as necessary. See Figure 4.

CHECKS, LIFT TRUCKS

MANUFACTURED AFTER AUGUST, 2012

AND EQUIPPED WITH FORK

POSITIONER

WARNING

Never repair damaged forks by heating or weld-

ing. Forks are made of tempered steel using spe-

cial procedures. Always replace damaged forks as

a pair.

1.

Inspect forks for cracks and wear.

2.

Check alignment of fork tips. Difference in

height of fork tips must be less than three per-

cent of fork length. See Table 2 and Figure 9.

Some applications may require closer align-

ment. If forks DO NOT meet specification they

both must be replaced.

3.

Check that the bottom of each fork is not exces-

sively worn.

Table 2. Fork Tip Alignment

Fork Tip Alignment Specifications

Standard Fork

Lengths

Maximum Fork Tip

Difference

1

mm

(in.)

mm

(in.)

1219

(48)

37

(1.44)

1981

(78)

59

(2.32)

1

Difference of alignment between fork tips must be

no more than 3% of the total fork length.

4000 SRM 1148

Fork Replacement

9

Содержание J160

Страница 1: ...Hyster J160 J30ZT J35ZT J40ZT Forklift...